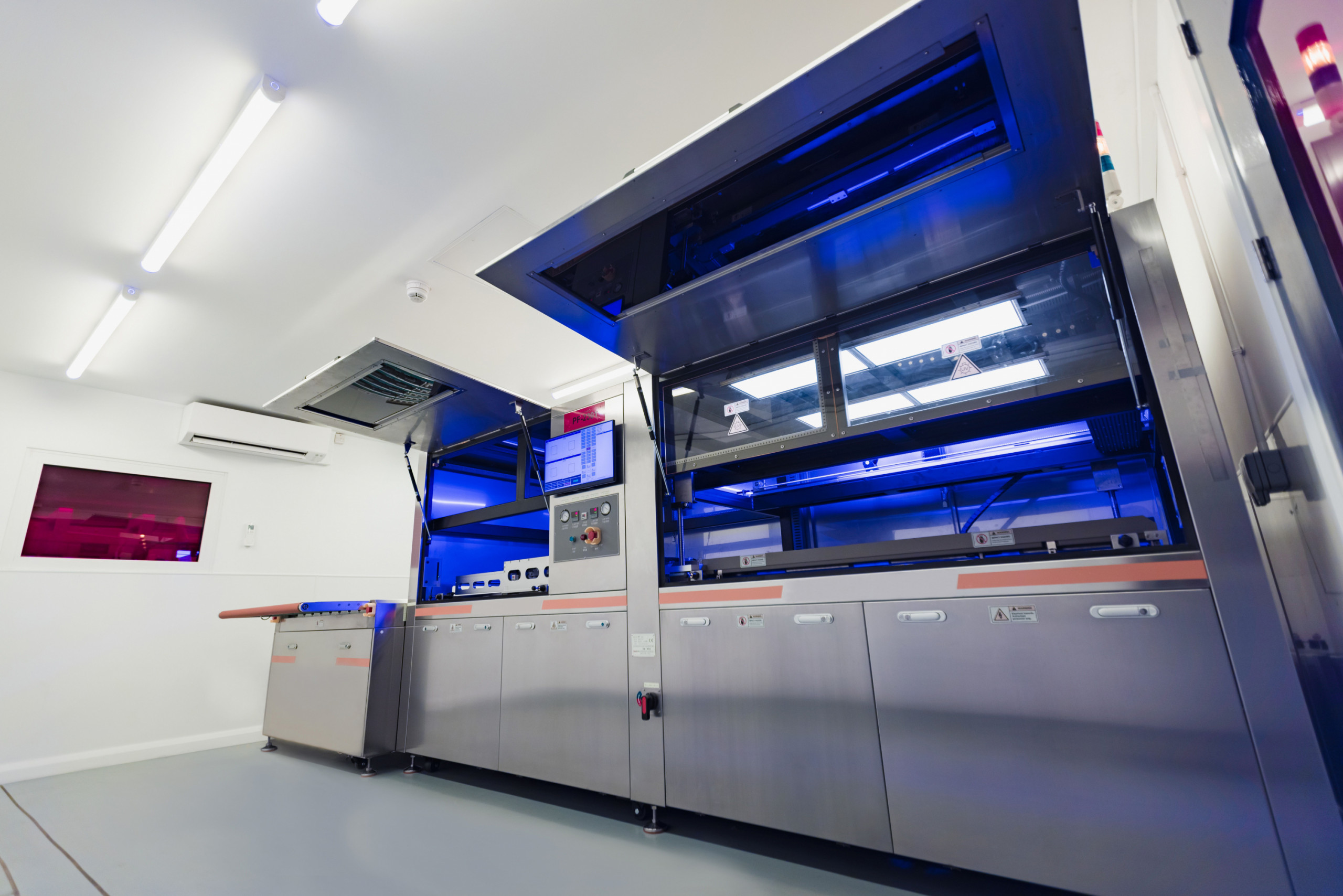

Precision Micro, a global supplier of chemically etched components, is investing in three new etching machines and dedicated semi-automatic print frames at its Fort Dunlop site in Birmingham to expand production capacity and capabilities.

© Precision Micro

With this investment of EUR 2.1 million, the new etching room contains three highly efficient etching machines and a special semi-automatic printing frame.

The new print frames are – probably for the first time in the industry – a design that prints photographic masks on larger metal sheets up to 1500 x 600 mm with minimal human intervention to increase throughput and offer customers more favorable costs. In addition, increased automation improves component quality by eliminating the problem of foreign bodies that can interfere with photochemical etching, while facilitating manual handling of the heavier material.

Driven by global demand for next-generation energy technologies, for example, hydrogen generation and storage, carbon capture, “green” energy storage, and electric and fuel cell vehicles, this expansion enables Precision Micro to supply larger and thicker etched sheet metal parts in higher volumes.

This investment in the production of components such as distribution plates for heat exchangers of printed circuits for heat loss recovery and hydrogen precoolers, connectors between busbars and batteries in electric vehicles, and bipolar plates for fuel cells and electrolyzers for hydrogen production, will benefit companies that want to use these products and overcome capacity constraints in the existing supply chain.

© Precision Micro

Karl Hollis, Precision Micro’s Technical Director, commented, “We have worked closely with our suppliers to develop this new equipment in line with our ESG strategy to automate large parts of our manufacturing process, use less energy and achieve the same consistent results. Chemical etching is often the only suitable method for producing the precision components needed for many new sustainability technologies. This latest investment of €2.1 million is the next stage in our expansion and we are pleased to be able to support our customers in their rapid growth.

In 2019, Precision Micro invested EUR 5.1 million in facilities and new equipment, increasing the company’s etching capacity by 30 percent to create new opportunities in renewable energy markets. The latest measure has brought about an increase of another 40 percent.

Precision Micro also plans to start up a fourth etching machine in the new etch room in early 2024.