Metal processors know the problem: handling long bars, tubes, profiles and sheets must be done efficiently and quickly. Kasto solutions automate all processes – from the storage of raw materials to the picking of sections. And with the digital offerings, the user always has an overview of everything. This significantly increases the efficiency of storage and sawing.

© Kasto Maschinenbau GmbH & Co KG

Companies in the metalworking industries, such as machine and window construction, sheet metal processing and steel trading, store and process large quantities of metals. The areas of application are diverse, the stored goods very different. In addition to long goods such as bars, tubes and profiles, the companies also handle sheet metal. The following applies: storage space is valuable and should be used efficiently. The same efficiency is also required when processing and compiling the individual orders.

Powerful, fully automatic saws perform straight cuts or miter cuts in the industry. Some companies still rely on costly or material-intensive sorting solutions for palletizing and picking.

Robot handling systems from Kasto can remove the offcuts directly from the sawing machine and handle them gently. In addition to this, Kasto offers further solutions for end-to-end optimization of the entire process chain. In seven steps, users can optimize their processes for sawing and storing long goods and sheet metal.

Well organized: the Warehouse Management System

A high-performance system is required to keep everything running smoothly in the warehouse. Kastologic manages all processes. The software optimizes the travel paths, supports the operator with a graphical interface and visualizes the system. ERP system and WMS automatically exchange data via standard interfaces. The efficiency and performance of the overall system increase, and operating and assignment errors are virtually eliminated. Users can customize the software precisely to their requirements with different modules. This includes the control of automated storage systems, the integration of machines and comprehensive statistics for system analysis.

Individually automated: the storage solution

© Kasto Maschinenbau GmbH & Co KG

Standardized bearings are suitable for many applications and different materials. But sometimes it has to be more: increased efficiency, greater space savings, faster provision, greater variance.

The Kasto modular system enables precise adaptation to the individual material flow. For example, input and output stations can be tailored to the user’s requirements – for example with automatic bar separation. Thanks to an individual design with selectable storage lengths and heights, all formats used can be accommodated in a space-saving manner.

As an intelligent distribution system, Kastorail transports picking bundles for dispatch just as efficiently and ergonomically as individual materials between the processing steps. It works with a combination of manipulator and material polder chain conveyors. Installation on raised rails ensures optimum use of space.

Clean cut: the sawing machine

Band and circular saws from Kasto cut bar materials, panels and profiles to size with straight or miter cuts. In addition to high cutting performance, users demand short non-productive times. This is why, for example, material qualities and the matching saw blade can be permanently stored in the saws. The control system automatically selects the cutting technique according to the job. This not only reduces tool costs, but also results in significantly shorter cutting times.

In addition, fully automatic CNC production circular saws such as the Kastovariospeed can cut any long product to size, regardless of the material quality. And the sawing solution can also work together with the Kastosort robot handling system if required.

Integrated cutting: the sawing center

In the Kastocenter, computer-controlled storage and retrieval machines transport individual long items fully automatically to an integrated CNC sawing machine and automatically return the remaining pieces to storage. The software keeps stocks up to date and can trigger new orders if necessary. The flexible system consists of a storage system, saw and control system. Kasto optimally coordinates the components – so the sawing center can do as much as three to seven individual saws.

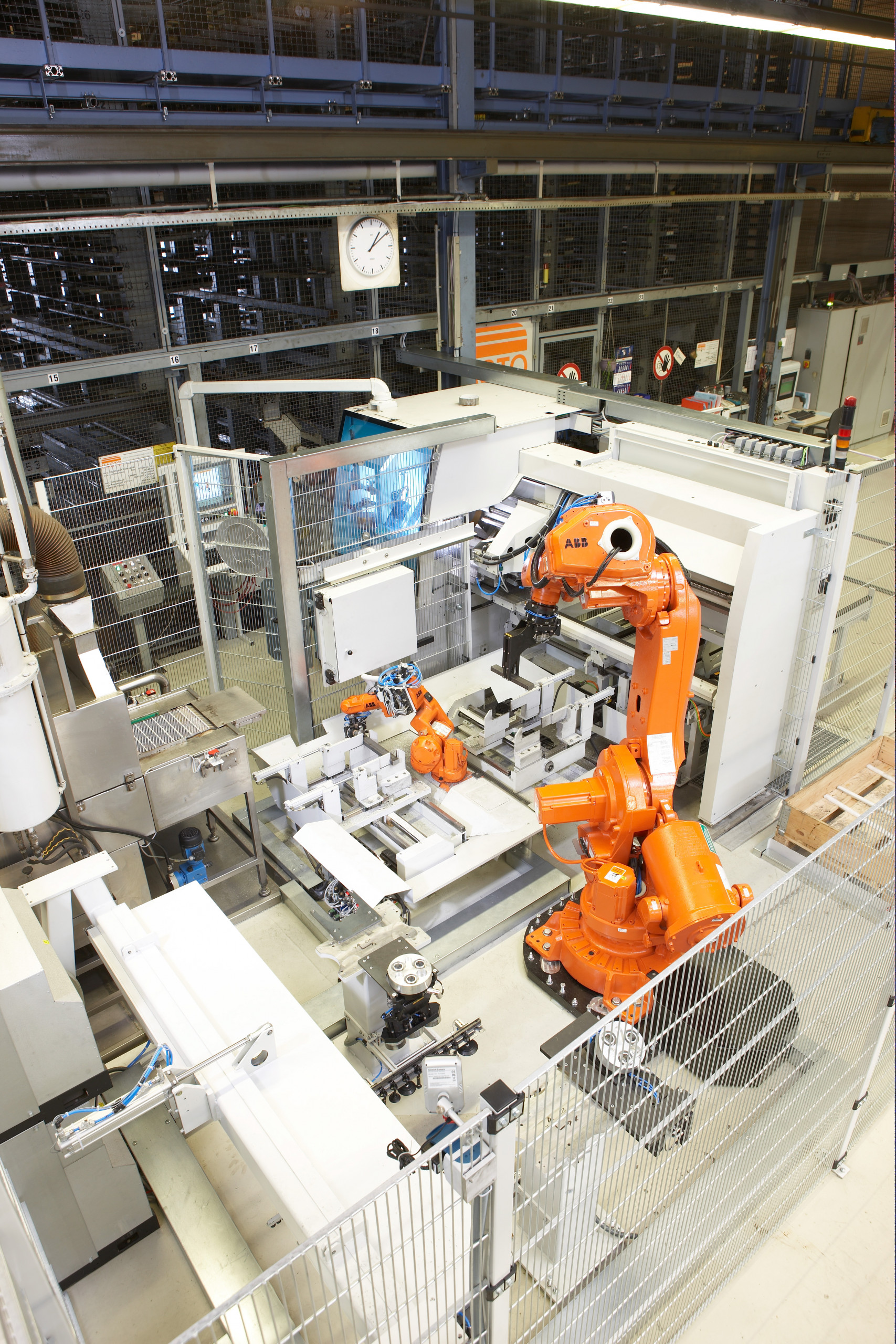

Everything in order: material handling

After sawing is before shipping. The sawing specialist has developed the Kastosort robot handling system to automate palletizing and order picking. It is waiting to be used directly behind the saw: to transfer workpieces to subsequent processes such as deburring, length measurement and marking or to pack them directly. To do this, the robot automatically calculates the stacking pattern with the highest packing density. It draws the required information directly from the ERP system. The decentralized, self-organized program logic eliminates the need for teach-in or programming by the user.

© Kasto Maschinenbau GmbH & Co KG

Always with you: the app

With the Kastoapp, users can keep an eye on the status of all Kasto sawing machines in the network. In this way, relevant parameters such as article, cut-off length, target and actual number of pieces and cutting speed are always present. Kastologic mobile supports employees in the warehouse. For example, you can simply trigger a reorder by scanning the QR and barcodes when removing the product from the magazine. If an error occurs in the operating process, the apps inform the user and enable a quick response.

A complete overview: remote maintenance

With the help of augmented reality, Kasto VisualAssistance offers an easy way to maintain machines and systems remotely. Service employees support users with operation and fault diagnosis via a direct remote connection. At its heart is an interactive app for tablets, smartphones or smart glasses.

Background

The Kasto Group, based in Achern, Baden (Kasto Maschinenbau GmbH & Co. KG), specializes in sawing, storage and automation technology for long metal products and sheet metal. The company is a global market and technology leader for metal sawing machines, semi-automatic and automatic long goods and sheet metal storage systems, automatic handling equipment for metal bars, sheets and blanks, as well as the associated intelligent software.

With 180 years of experience, Kasto is one of the oldest family businesses in Europe. 170 patents, more than 140,000 sawing machines delivered all over the world and over 2,400 automatic storage systems installed testify to the company’s success. In addition to a branch plant in Schalkau, Thuringia, Kasto has subsidiaries in England, France, Singapore, China, Switzerland and the USA as well as sales and service partners in many other countries.

Web:

www.kasto.com