What is the climate impact of a press hardening line during its lifetime? And how does the use of press-hardened parts affect the climate performance of vehicles? This information is requested by many vehicle manufacturers and can now be provided by AP&T.

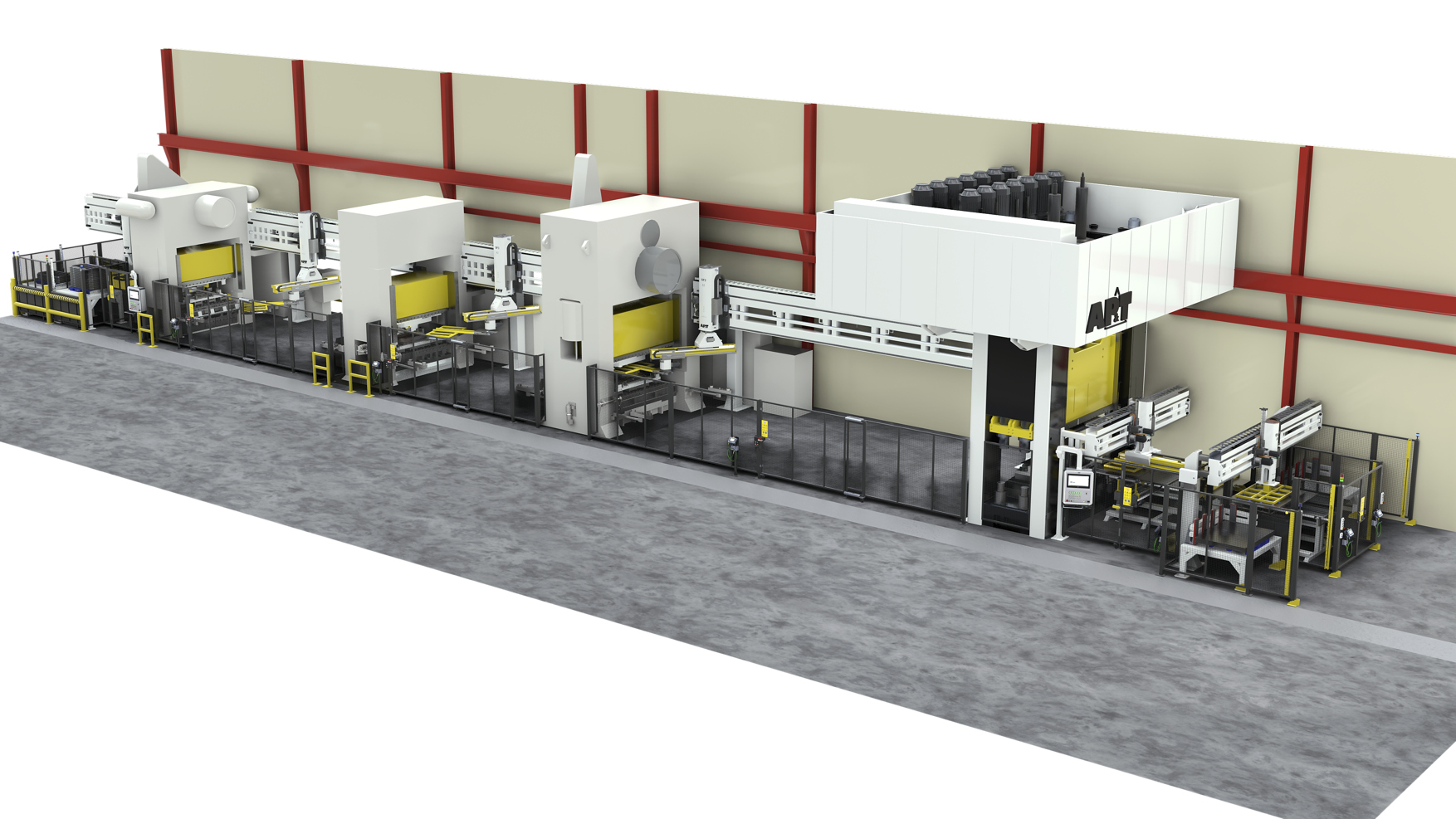

In cooperation with the Swedish research institute RISE, AP&T has comprehensively analyzed the life cycle of a typical press hardening line. The analysis covers climate impacts at all stages of a plant whose expected useful life is 20 years, from iron ore extraction to recycling of the machine at the end of its life. Ongoing maintenance and a rebuild have also been included in the calculations.

In addition, they have analyzed how the overall climate emissions of the final product – a passenger car – are affected by the components used in its structure.

“The data that life cycle assessments provide primarily give us a stable basis for our own further climate work and help us prioritize more easily which measures we should focus on. In addition, we can provide our customers with a third-party verified, factual basis that helps them calculate and report the total climate impact of their products and make the right decisions for the future,” explains Christer Bäckdahl, CTO at AP&T.

Many factors influence the result

The extent of the climatic impact of a press hardening line during its life cycle depends on many parameters that vary from case to case. In general, AP&T’s analyses show that the majority of climate emissions are related to energy consumption during the operational phase. However, the extent is largely determined by the energy mix, that is, the energy sources used to generate the electricity needed to operate the facility. Hydro and wind power have little impact on climate, while emissions from fossil fuels such as coal, oil, and fossil gas are significant.

“This leads to different results depending on where the generation takes place. For example, the Swedish energy mix has only one-fifth of the climate impact of the UK. But regardless of where production takes place, it is always important to optimize energy consumption and choose energy-efficient alternatives. Take our servo-hydraulic press, for example, which is up to 70 percent more energy efficient than our conventional hydraulic presses.”

An interesting question is what the climate performance of a finished car is during its life cycle, taking into account the materials used to manufacture the structural parts. When you factor in the steelmaking process and how the parts are made, which is better: press-hardened steel or cold-formed high-strength steel?

“Thanks to the fact that press hardening strengthens the steel, less material is needed for the individual parts. This reduces the weight, making the car lighter than when cold-formed steel is used. This has a positive effect on the car’s energy consumption and climate impact, and far outweighs the emissions generated during material production and component manufacture,” says Bäckdahl.

With many automotive manufacturers asking for the kind of information that lifecycle analysis can provide, AP&T expects to see more analysis of specific equipment and products in the future.

“We will continue to expand this offering because we know many customers will benefit,” Bäckdahl says.

Also in cooperation with RISE, AP&T recently carried out a corresponding life cycle analysis of a production line for the hot forming of high-strength aluminum.

AP&T at the Blechexpo

Under the motto “One Responsible Partner”, the company will present its total offering for the sheet metal forming industry. Market-leading products and new business models offer customers the best conditions for maximum performance and sustainable profitability over the entire useful life of their assets.

AP&T offers turnkey solutions for fiber and sheet metal forming based on its extensive knowledge of processes and machinery and its long-term commitment to its customers’ business. The company’s overall portfolio includes complete production lines with presses, automation, tooling, heat treatment equipment and services such as maintenance, spare parts supply, optimization and rebuilds.

Hall 8, at booth 8501

Web:

aptgroup.com/en