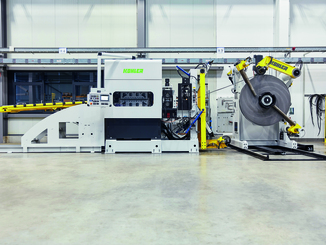

Sheet Metal Coils

Threading tools for sheet metal working

As soon as internal threads are produced in sheet metal working, the tool of choice is the thread cutter – also known as thread former. Compared to classic thread cutting, […]

Copyright: bbr Bänder Bleche Rohre - bbr Bänder Bleche Rohre ist eine eingetragene Marke der Hanser Verlag GmbH & Co. KG