Siblings Susanne Kunschert and Thomas Pilz, Managing Directors of Pilz in Ostfildern, report on the 2022 financial year and provide an outlook for 2023. Excerpts from their speeches.

2022 was both a difficult and a positive year for Pilz. On the one hand, the terrible news about war and natural disasters. Added to this were the interruptions in the supply chain and the shortage of components, which meant many difficult negotiations and sometimes emotional discussions with suppliers as well as customers for Pilz employees.

But, on the other hand, we at Pilz have together managed to make the best of such unfavorable and imponderable economic conditions. That is why there is great joy throughout the company at the good result: in 2022, Pilz achieved 403.3 million euros in sales, representing growth of 15.8 percent – more than the industry as a whole. This means that despite the supply chain and component problems, Pilz has produced and shipped more units than ever before.

“We owe this to our comparatively good ability to deliver and thus to the employees who work so tirelessly beyond today to ensure that we can produce and deliver. My mother Renate Pilz coined the phrase that we don’t just want to work together, but for each other. For each other for the customer. That is what makes us strong and that is what has sustained us. For this, my brother and I would like to take this opportunity to thank all our employees worldwide for their commitment and their heart and soul, with which they work for the company and our customers every day,” praised Susanne Kunschert.

The export share rose by 1.1 percentage points to 76.3 percent in 2022. Pilz has grown particularly strongly in Asia. However, Germany remains the largest single market for Pilz.

© Pilz

Focus remains on delivery capability

In general, the supply chains have stabilized and component availability has improved – but there can be no talk of a sustained easing of the situation. Individual components are temporarily no longer available from one day to the next. One of the main tasks of purchasing is therefore still escalation management. Semiconductors, for example, are now more readily available, but the bottleneck still exists, goods have to be allocated and delivery times often exceed one year. Therefore, Pilz continues to prioritize the issue of delivery capability. The task force on the supply chain remains in place. Pilz has been able to make up a large part of the backlog in recent months. However, this was only possible with additional shifts, for example at night or on Saturdays.

75 years mushroom

This year, Pilz celebrates his 75th birthday. In 1948, during the economically difficult time after World War 2, Hermann Pilz, the grandfather of Susanne Kunschert and Thomas Pilz, founded a glassblowing company in Esslingen. In the 1960s, his son Peter Pilz, father of the two current managing directors, transformed the company with his pioneering spirit from glass apparatus engineering to electronics, and he initiated not only the technological change but also the internationalization that still characterizes Pilz today. He founded the first subsidiaries in the 1970s – in Austria, France and Switzerland.

Thomas Pilz looks back: “In the early 1970s Pilz was one of the first companies in Europe to launch PLC systems on the market. In the 1980s, by now under the leadership of our mother Renate Pilz, the company then established modern, electronic machine safety with the PNOZ, the world’s first safety relay. In the 1990s and 2000s, Renate Pilz recognized the possibilities of digitalization for automation. Since the end of 2017, my sister and I have been running the company together, as managing partners in the third generation.”

So Pilz has changed again and again. Common to all times of change is the joy of innovation, says Thomas Pilz. But also: “Our Christian values are our roots, our foundation. They are expressed in the interaction, trust, reliability and helpfulness at Pilz. … That’s how we were able to take on challenges and become the company we are today. We look back on our anniversary with deep gratitude and full of joy. Our employees make our company. In this gratitude we include our suppliers and our customers, because without customers no company, without suppliers no production. We have developed from the founding generation to an established medium-sized company today. That’s not something you can take for granted.”

And he continues: “The company’s existence has to be earned anew every day. Pilz will continue to exist because the company will continue to change. It’s a question of continuing to develop, because standing still is harmful to any organism. That means we will continue to work on the technical challenges and take advantage of the opportunities that present themselves.”

Sustainability is firmly anchored

Thomas Pilz continues: “It is our duty to ensure that future generations can live in a world in which they can feel safe, healthy and comfortable. It has always been anchored in our corporate objectives that we want to work and produce in ecologically designed buildings, in an environmentally aware, energy-saving and cost-conscious manner. This is how we understand sustainability at Pilz holistically – for people, machines and the environment.”

Pilz published its first sustainability report in accordance with the German Sustainability Code. The second, then international report, will follow this year. Occupational safety is a priority at Pilz. Management wants to create a work environment that promotes employee health. Therefore, in recent months, work has been done on an important certification. The result: Pilz meets the first international standard for occupational health and safety management systems, ISO 45001.

Pilz focuses on quality

High product quality also means fewer returns and less scrap. Should a device nevertheless be defective, Pilz offers customers the option of returning it to us. The employees at the Repair Center check to what extent the defective device can be reused by repairing it or by replacing individual components. In addition, customers in Germany are offered the opportunity to take back products at the end of their life cycle. In the past, Pilz has already been able to increase the recycling rate of waste to 95 percent.

Because the company wants to minimize CO2 emissions, it has determined the CO2 footprint for one product as an example. The result: The polycarbonate casing has the largest share of CO2 emissions in this case. That is why the development department is currently working intensively on the switch to “greener” plastics. Pilz is also cooperating closely with Linz University of Applied Sciences in a research project to develop environmentally friendly materials. Pilz equipment used for machine safety must comply with the specifications of the various international testing authorities This naturally also applies to recyclable or bio-based plastics.

Presence or digital: the mix makes the difference

Especially the work on such future topics requires the exchange, the community of people. The best way to achieve this is to be present in direct interaction. “At Pilz, we are therefore extremely pleased that our employees will be able to return to their workplace at the company once the Corona pandemic is over. After all, this is the center of work. Of course, we offer our employees the opportunity to work on a mobile basis two days a week. This gives them more flexibility and thus makes it easier to balance family and career. Ultimately, it’s the mix that makes it!” promises Thomas Pilz.

Plus also for headcount

Pilz employed 2,399 people in 42 countries worldwide as of December 31, 2022. This is an increase of 2.7 percent. In Germany, the number of employees was 1,010 (reporting date Dec. 31, 2022), an increase of 1.7 percent. Pilz traditionally places great value on strong in-house training: At its headquarters, the company had 43 trainees on December 31, 2022, including 21 students from the Baden-Württemberg Cooperative State University (DHBW). In 2023, the aim is to enable a further 21 young people to start their careers, 8 apprentices and 13 DHBW students. One focus of our global human resources activities is training and knowledge transfer. Last year Pilz successfully rolled out an international competence management system for 220 employees in the engineering and consulting departments. In this way, Pilz is achieving its goal of being able to offer its customers services, i.e. consulting, engineering and training, at a uniform level in all subsidiaries worldwide.

Further investments planned worldwide

“Uncertainties and crises will continue to accompany us. We had to and have to accept the way things are and always make the best of it and put all our energy into creativity,” Susanne Kunschert expects. “At Pilz, we have always reinvested our profits in order to be able to continue to grow independently. By 2025 we want to invest around 38 million euros at our global production sites at our headquarters in Ostfildern (Germany), in Betschdorf (France), Bad Ragaz (Switzerland) and Jintan (China), for example in the expansion and renewal of SMD production, relay production and intralogistics. The aim is to remain flexible by means of networking and digitization, for example by using driverless transport systems or building an automated warehouse.”

In this way, Pilz not only increases efficiency and capacity, but also meets the technical challenges to plants such as miniaturization in electronics or the shortage of skilled workers. “The investments in our existing plants are also a commitment to our production sites, three of them in Central Europe. Ostfildern in particular, as our headquarters, is and will remain the place where our entire value chain plus development, IT and HR are based,” confirms Susanne Kunschert. “Development and production belong together at Pilz. Pilz has made a good start to 2023, and we are aiming for renewed growth in terms of sales and headcount, despite the continuing difficult conditions. Looking ahead to 2023, we are still a long way from being able to talk about a normal year again. But we are moving forward optimistically – with a joyful ‘Yes!’ to what lies ahead for the company,” she concludes.

75 years mushroom

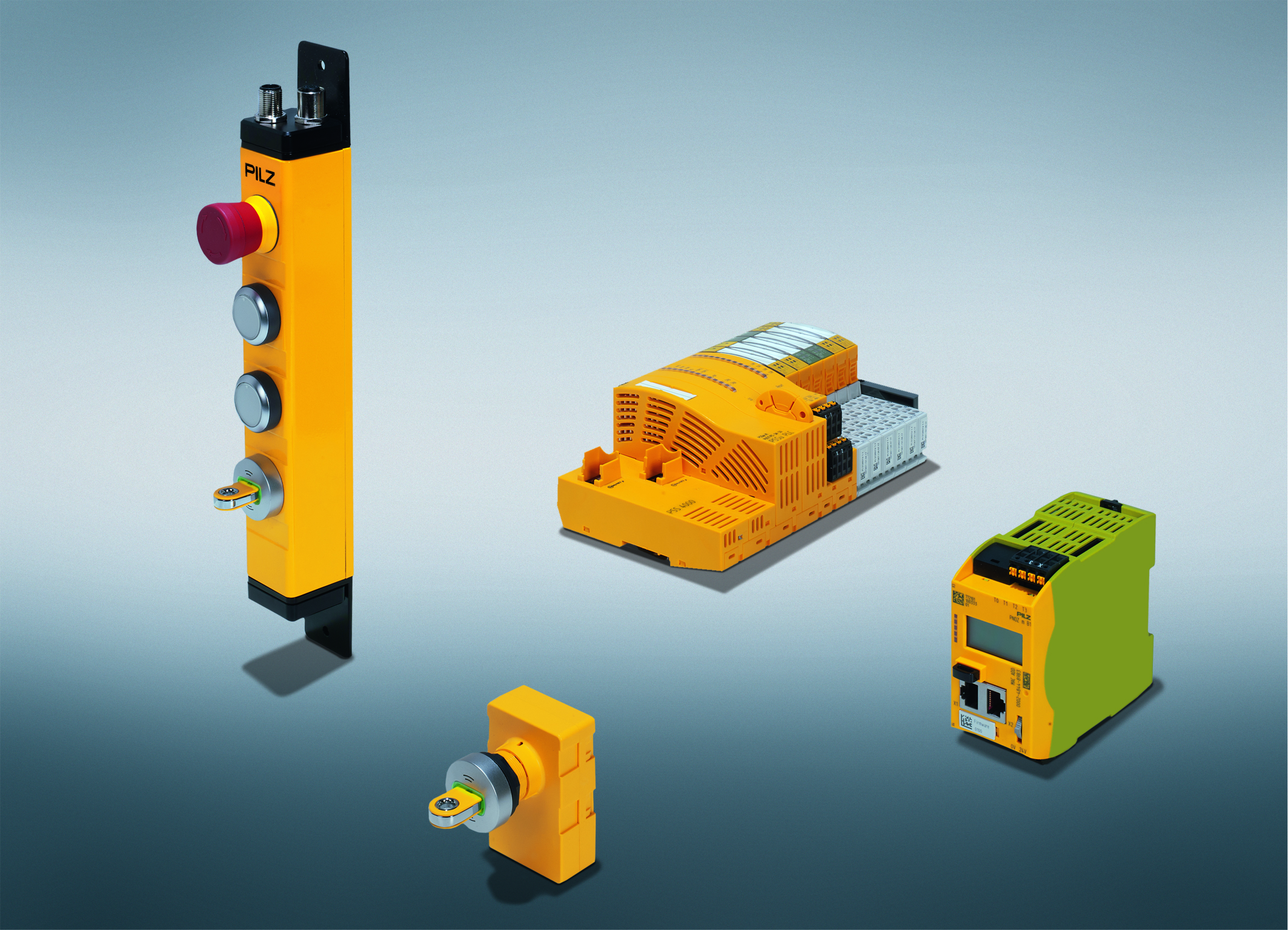

As a global supplier of products, systems and services for automation technology, Pilz 2023 can look back on a 75-year success story: Founded in 1948, the Pilz Group now employs around 2,500 people in 42 subsidiaries and branches. The pioneer of safe automation, headquartered in Ostfildern, Germany, creates safety for people, machines and the environment worldwide with its complete automation solutions. The portfolio of the technology leader includes sensor, control and drive technology as well as systems for industrial communication, diagnostics and visualization. An international range of services including consulting, engineering and training rounds off the portfolio. The solutions for safety and security are used in numerous industries beyond mechanical and plant engineering, such as intralogistics, rail technology and robotics.

Specialist forum “Safety + Automation” – Complete program available

The complete program for the popular “Safety + Automation” specialist forum is now available on the Pilz website. The forum will be held for the first time as part of Moulding Expo at Messe Stuttgart (June 14, 2023). Visitors will learn everything they need to know about safety and security in a program of presentations covering a wide range of topics. The forum will focus on practical applications from the field of machine safety, including safety and security in machine and plant construction, as well as the amendment of the Machinery Directive (MRL) to the Machinery Ordinance: What is a “significant change” to machines and plants? How is a safety assessment of existing machines carried out? What are the latest developments in EN ISO 13849-1 or the new machinery regulation? How is the future shaping up in terms of machine safety? Visitors to Moulding Expo will find the technical forum in the atrium at Hall 1, directly at the East Entrance.

Web:

www.pilz.com