The FairXperts anniversary event stands for optimal knowledge transfer and effective information gathering on technologies for deburring, precision surface manufacturing and industrial component cleaning. These are topics that are becoming increasingly important in manufacturing due to transformation processes and higher quality requirements. The 10th Symposium Deburring Technologies and Precision Surfaces will be held on 17th and May 18th, 2022 at the K3N in Nürtingen.

Changing requirements for the properties of surfaces, new and modified manufacturing processes, the trend towards automation and digitalization of manufacturing processes, and the demand for sustainable production are just some of the challenges that have to be mastered as a result of structural change in further areas of industry. They also have an impact on manufacturing steps such as deburring, the production of precision surfaces, and component cleaning.

In order to be able to meet requirements in these areas in the best possible technical and economic way, information and knowledge about new developments and trends are just as indispensable as best-practice solutions. These topics will be the focus of the 10th specialist conference on deburring technologies and precision surfaces organized by fairXperts GmbH & Co. KG.

Concentrated know-how for optimized processes

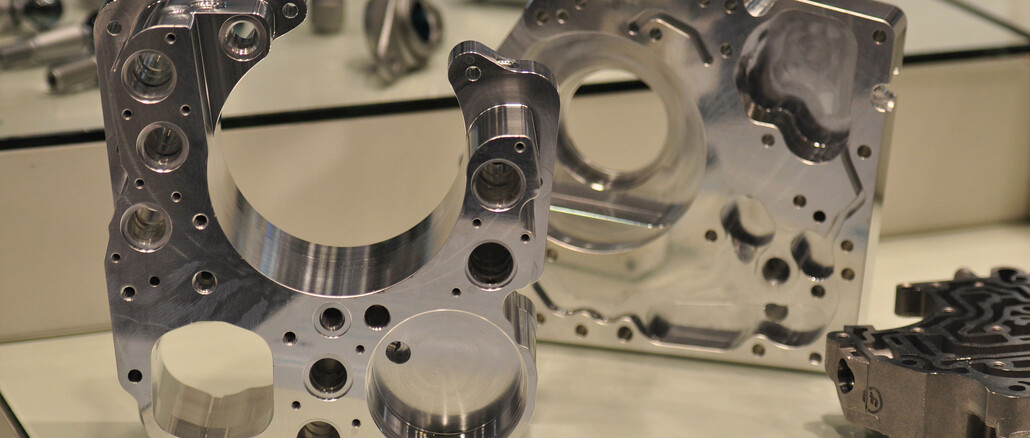

The anniversary event of the private trade fair and conference organizer will be held on 17th and 18th May 2022 in the culture and conference center K3N in Nürtingen. It is divided into six thematic blocks. The session “Mechanical deburring with tools” provides information on innovative deburring solutions for series production. Among other things, effective technologies for deburring cross holes of less than two millimeters and for machining multiple cross holes in a single operation will be presented.

The lecture series “Mechanical deburring with special systems”, for example, will focus on a new blasting technology for highly efficient, energy-saving and gentle processing of components and surfaces made of metal and plastic. Efficient solutions are also presented for the machining of cross bores as well as internal surfaces.

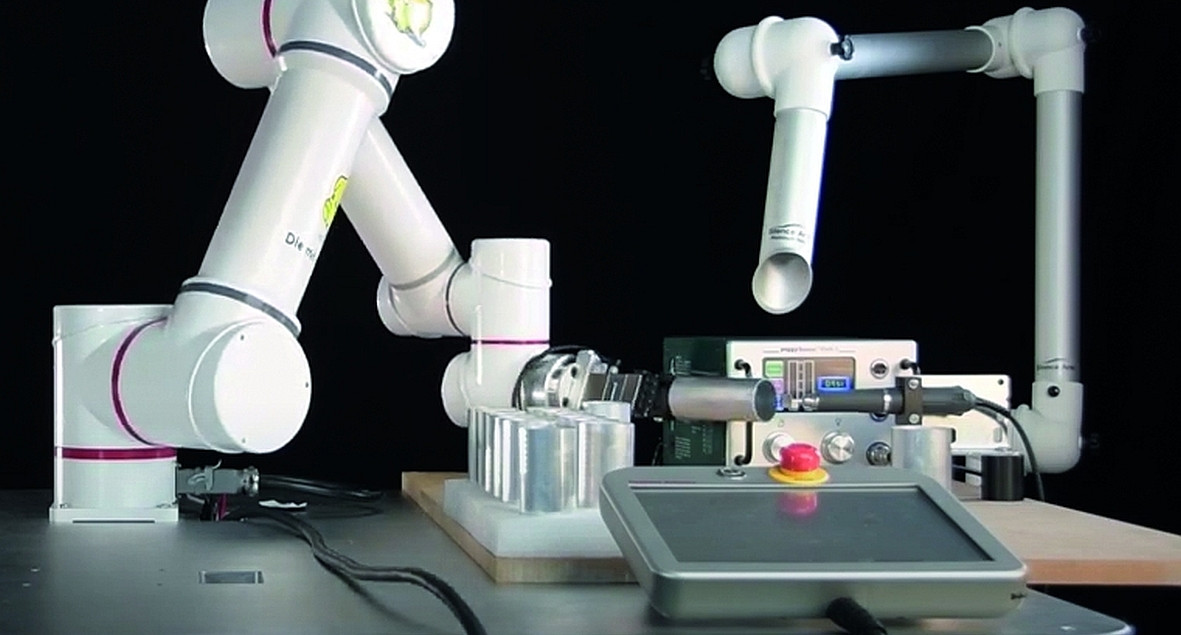

Non-contact deburring with ultrasound as well as the basics, areas of application and advantages of laser deburring are addressed in the block “Non-mechanical deburring with special machines”, as are the technical and economic aspects under which the use of electrochemical deburring in production makes sense. The ever-increasing tendency to automate production processes will be addressed at the conference with the topic block “Mechanical deburring with industrial robots”.

Whether it is the quality of subsequent processes such as coating, bonding and assembly, or ensuring perfect component function – clean workpieces in line with requirements are a must. The session “Cleaning surfaces with process reliability – removing burr residues” will provide information on solutions for achieving the required component cleanliness in a stable and efficient manner and on the role played by the design of the pre-processes.

Increasing requirements and demands

Increasing quality requirements and more stringent demands on traceability also require systematic and reproducible recording and documentation of the results achieved in surface engineering processes such as deburring. Solutions for this will be presented in the lecture block “Automated quality inspection of surfaces”.

The lecture program will be rounded off by an accompanying exhibition. At this event, participants benefit not only from the presentation of new developments and practice-oriented process solutions, but also from the direct exchange of experience with experts. It thus offers valuable suggestions for process optimization in one’s own operation. The target group of the conference are specialists and managers from production, work preparation, technology, process engineering, quality assurance as well as development and design of the various industrial sectors.