In the production chain, the quality of processes such as coating, bonding, welding and assembly depends crucially on the cleanliness of the components. Component cleaning must therefore ensure that the respective cleanliness requirements are achieved in a stable and economical manner. The basic seminar “Quality assurance in component cleaning” imparts the necessary knowledge in theory and practice. The event on employee qualification will be held by the Fachverband industrielle Bauteilreinigung (FiT) e. V. on 1. and 2 December 2021 in Frankenthal.

In the manufacturing chain of production, component cleaning is a quality-critical production step in all industrial sectors that has gained enormous importance. The cleaning expertise of the employees is therefore an essential building block in order to ensure the component cleanliness required for subsequent processes such as coating, bonding, heat treatment, welding and assembly, not only in a stable manner, but also economically and to avoid costly reworking or even rejects. However, as this know-how is not taught in training or studies, there are often large gaps in knowledge in this area.

With the basic seminar “Quality assurance in component cleaning”, the Fachverband industrielle Teilereinigung (FiT) e. V. offers a corresponding qualification solution for personnel in this field. The event, organised by fairXperts GmbH & Co KG, will take place on 1. and 2 December 2021 in Frankenthal, Palatinate.

For maximum learning success, the number of participants is limited to 40. Understanding, designing and controlling cleaning processes In this seminar, experienced experts from the cleaning industry give lectures on the basics of how component cleanliness can be achieved stably and efficiently through efficient quality control and optimised processes and plant technology.

The topics of the theoretical part are:

– Quality assurance in component cleaning

– Chemistry of the cleaning process: aqueous and solvent

– Process and plant technology: aqueous and solvents

– ultrasonic cleaning technology

– Component design and batching suitable for cleaning, product carriers

– Policies and procedures – Recommendations for users

– Process and plant engineering: Bath maintenance and media preparation

– Monitoring of the process media

– Control of component cleanliness

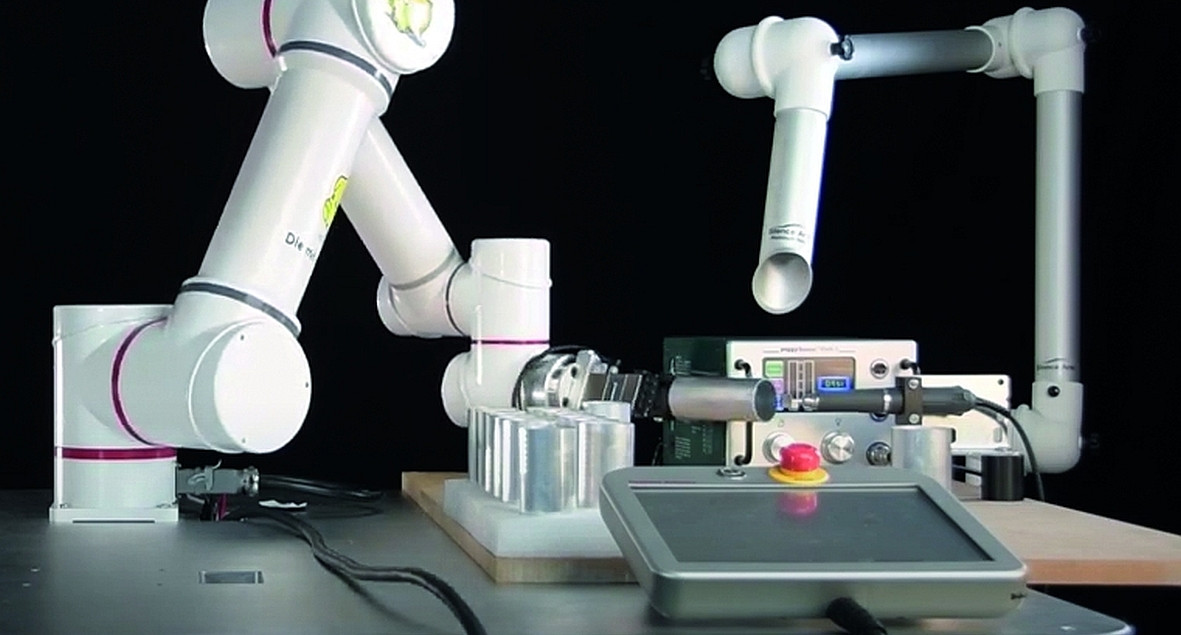

In the practical courses, the modes of action of cleaning mechanisms are demonstrated and approaches to their practical and effective use are shown. In addition, the participants learn about proven measuring devices and measuring methods and their use in everyday practice.

Internship Topics:

– ultrasound

– Chemistry: emulsifying, demulsifying

– Selection of the cleaning concept

– Checking component cleanliness – filmic contamination

– Checking component cleanliness – particulate contamination

– Surfactant control with bubble pressure tensiometers

– Builder control with ultrasonic sensor technology

With this programme, the FiT’s basic seminar is aimed at specialists and managers from development and design, technology and work preparation as well as production and quality assurance. The industries addressed include the automotive industry, mechanical engineering, electrical engineering and electronics, precision mechanics, optics, surface and coating technology, medical technology and other industrial sectors in which component cleanliness is a quality criterion.

Web:

www.fit-online.org