With the Powercut 2 swing-cut shear, RAS has reinvented the operation of industrial swing-cut shears. 3190 x 6.3 mm cutting performance, torsion-free cuts, a clever material sorting system and a redesigned operating concept open the door to a new generation of shears.

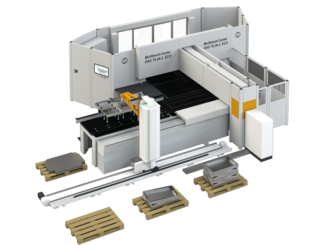

The large and clearly arranged 15″ touch monitor on the new RAS Powercut 2 immediately catches the eye and can be moved along the entire front of the machines. In front of the LED-lit cutting area, large-area and beveled table plates with ball rollers facilitate material handling. Recessed grips between the table plates and deep recesses in the finger guards ensure good material utilization with maximum safety. The working level, raised to 850 mm, offers the best ergonomic conditions. With the mobile table extensions, even large metal sheets are optimally supported.

High speed in kerf setting and fence positioning were also the focus of RAS engineers. Even in the standard version, the backgauge has a depth of 1000 mm, which can be optionally extended to 1250 mm or 1500 mm. The very flat cutting angle between the upper and lower knives produces torsion-free cuts even with strip widths of about 10 to 15 x sheet thickness. The cutting length can be individually adjusted and a fast sequence of up to 64 strokes per minute ensures brisk cutting speed and high throughput.

The integrated cuttings sorting system separates good parts from scrap and can discharge the blanks at three different angles of inclination. Depending on the sensitivity of the material, the blanks can thus be discharged quickly or gently. With the return transport function, the machine returns cut sheets to the front of the shear table. This significantly reduces travel and handling times for the operator.

The safe discharge of small parts that enter a container on the front of the shear has been redesigned. Cuttings fall into a large-volume scrap container that can be pulled out from under the shear in different directions, depending on the space available. For maximum speed when cutting small or narrow components, the sorting system remains in a down position.

The safety and maintenance concept is also designed according to the latest findings. The hydraulic tank, for example, is located on the side of the machine stand and is easily accessible for oil changes. Large side recesses simplify knife changes, which are rarely necessary anyway due to the gentle swing cut.

The highlight in terms of operator ergonomics, however, is undoubtedly the completely new 15″ touch control. Due to the large screen and the operating functions displayed purely with icons, input is very fast and intuitive. Casual users of the shear can enter only the basic inputs in the manual operation, such as sheet thickness, material type, stop dimension and number of pieces.

More experienced users choose the advanced mode. Here, the sorting functions and the selection of the cutting length are possible in addition. Experts can enter an entire cutting program. There, several program lines can be processed one after the other as complete cutting jobs. The programs can be saved and reloaded for later use.