Bruderer presented two innovations at Blechexpo 2025: the B3 machine control for BSTA automatic punching presses and the BSP punching package control for rotor-stator production. Both premieres are characterized by higher process reliability, intuitive operation and maximum productivity with high quality. The BSP is available as an option fully integrated into the machine control system or as a stand-alone solution.

At Blechexpo from October 21 to 24 in Stuttgart, Bruderer will be demonstrating its new products live in action, together with a BSTA automatic punching press, the BSV servo feed and a partner tool from Erich Grau GmbH.

© Bruderer

The new standard for automatic punching presses?

The B3 control system is a completely new development based on the experience gained from over 5,000 installed B and B2 systems. It is intuitive to operate, which minimizes the amount of training required. Its user interface with tile look can be freely configured; role-based access rights increase security. The 21-inch touchscreen allows direct access to all functions of the punching press and connected peripheral components – including those from third-party suppliers.

Installation and set-up have been made more flexible and process control has been enhanced. For the first time, tools, slides and turning stations can be set up and monitored automatically at the touch of a button using an intelligent parameterization system. This means that automatic punching presses can be monitored with less effort.

Reliable: now and in the future

The tool, pressing force and position are controlled in a central operating window. Additional envelope curve monitoring promptly indicates changes to individual modules, allowing errors to be detected more quickly. If the BSP punching package control is used, an integrated continuous strip thickness measurement also contributes to greater process reliability.

OPC UA interfaces enable end-to-end networking with machines, production control systems and IIoT applications. The B3 control system will be available on new machines from 2026; existing Bruderer automatic punching presses can be retrofitted from mid-2026.

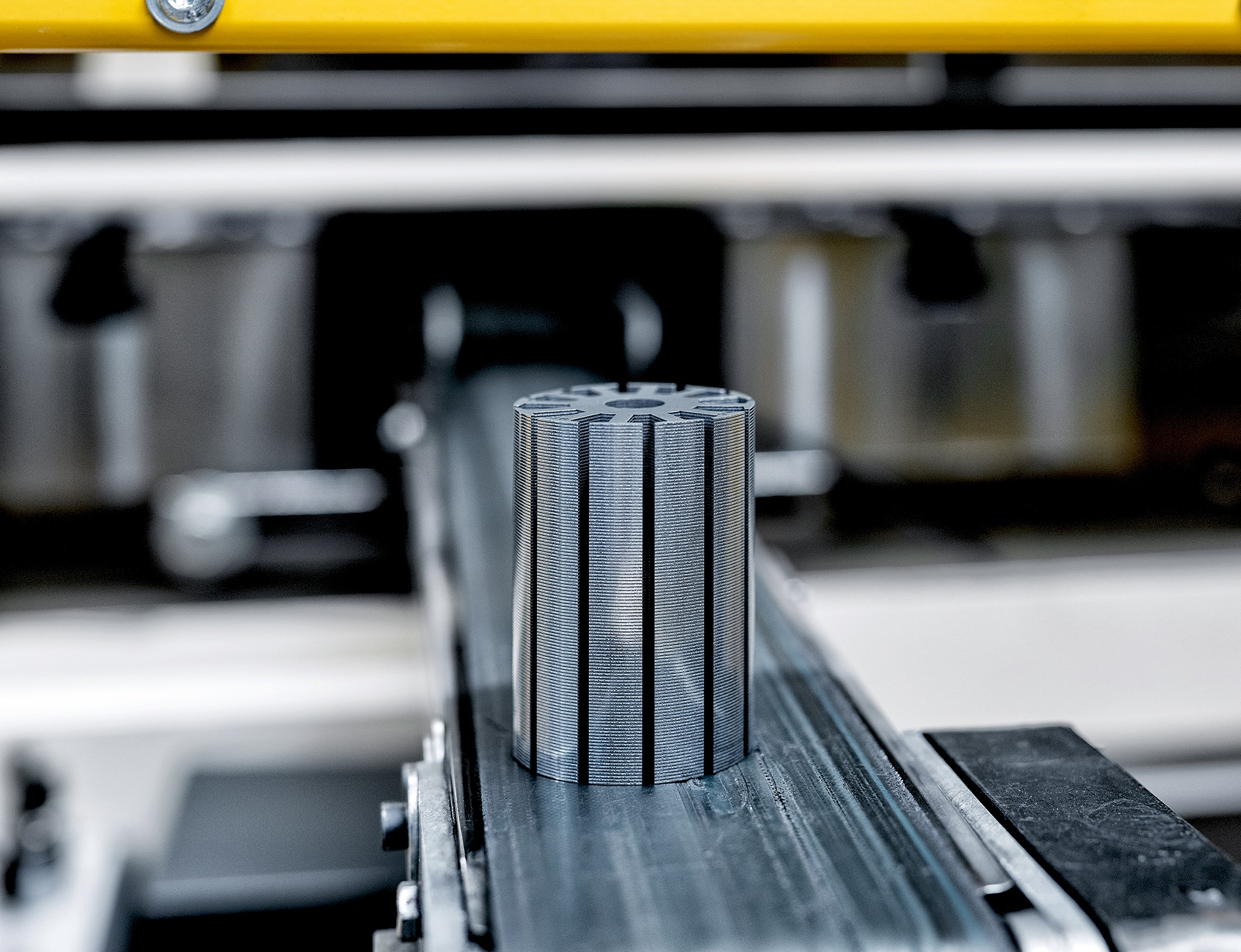

BSP: Specialized in rotor-stator production

The new BSP punch packaging control is an efficient solution for the growing market for the production of electric motor and transformer components. The system is based on B3 technology and enables complex packaging strategies with simple operation.

The BSP supports high-precision packaging strategies with up to eight program channels available in parallel. Reusable sheet shapes, diagnostic and statistical functions and the export of relevant process data facilitate optimization in line with Industry 4.0.

A key feature is the automatically configuring components, which speed up set-up and reduce the risk of errors. Up to six turning stations can be set up via plug-and-play, motors are automatically detected, parameterized and monitored. Slides and tool locking devices also set themselves up automatically, eliminating the need for time-consuming manual adjustments.

Extensive process control

The BSP also integrates comprehensive measuring and monitoring technology. In addition to position monitoring for up to eight channels, it offers a patented strip thickness measuring system with package height regulation. Material fluctuations from ±0.01 mm are detected inline and automatically compensated, ensuring constant product dimensions. The new BSP punching pack controller is now available integrated into the B3 controller and as a stand-alone version.

Background

Bruderer AG develops and manufactures durable, high-performance precision automatic punching presses with press forces of 180 to 2500 kN for µ-precise punching and forming with up to 2300 strokes/min. The product range also includes servo, roller and gripper feeds. The owner-managed family business also undertakes contract manufacturing of stamped parts on a small scale. The export share amounts to around 95 percent.

Bruderer supplies its systems to customers worldwide in the automotive, electrical and electronics, watchmaking, medical technology and packaging industries.

High-precision stamped parts, connectors and rotor-stator laminations manufactured on the Swiss precision systems can be found in numerous everyday objects: In cell phones and computers, vehicles, watches, medical devices as well as in kitchen appliances, furniture and an increasing number of electric motors in all industries.

The company was founded in 1943 and, in addition to its production site in Frasnacht (Switzerland), has numerous subsidiaries, competence centers and branches around the world. This enables Bruderer to provide fast service and a reliable supply of spare parts worldwide.

Hall 6, Stand 6309