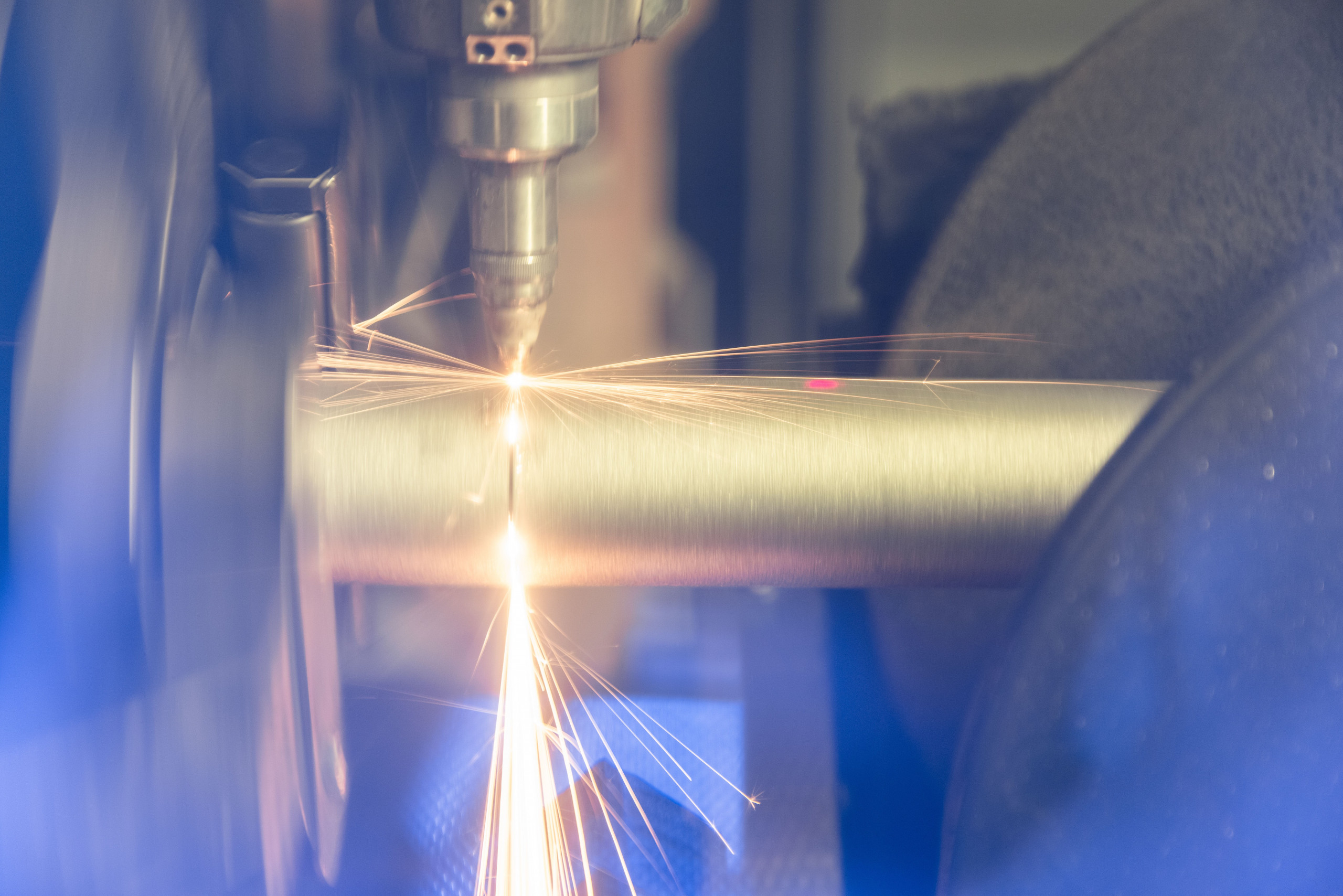

At the Tube trade fair in Düsseldorf, Trumpf presented a new unloading automation system for its laser tube cutting machines.

With the “unloading automation interface with longitudinal conveyor belt”, the laser tube cutting machine automatically forwards the cut tubes to an automation system that sorts the components or delivers them to downstream operations for further processing. This avoids errors and reduces operator involvement.

“The technology proves once again that Trumpf, as a solution provider, responds optimally to the requirements of metalworking companies. The high level of operator involvement in laser tube cutting is a major challenge for many companies. Our solution helps them to counteract the shortage of skilled workers and better utilize their machines. This gives them productivity and competitive advantages,” promises Product Manager Raphael Heinzelmann from Trumpf. Compared to many other technologies, the operator involvement with laser tube cutting is high. Due to the very high productivity of the TruLaser Tube machines, a production employee must regularly sort the cut tubes.

In times of a shortage of skilled workers, many companies lack the personnel to do this. In addition, the cut pipes are usually large and unwieldy. It is therefore difficult for companies to recruit employees for this task. Trumpf’s unloading automation provides a remedy here. Trumpf offers the solution for its TruLaser Tube Series 5000 and 7000.

Particularly suitable for medium and high quantities

With the new solution, the cut pipes are automatically fed onto a conveyor belt. This transports the components into the safety area of the automation system. An integrator takes them from there and processes them further, for example a robot or a handling device. When it comes to integrators, Trumpf relies on solutions from well-known partners such as Starmatik and Transfluid. In addition, the open concept of the laser cutting machine is retained and it is still possible to unload the components manually without any restrictions. This is particularly advantageous for small batch sizes or intermediate production runs.

Trumpf’s unloading automation system also has a digital interface that transmits all relevant information about the components to the integrator. The Trumpf programming software Programming Tube automatically makes this data available to the integrator via the digital interface of the TruLaser Tube. For example, the Starmatik robot can sort the cut parts or transport them directly to the next work step without having to teach individual positions.

In addition, the digitization solution saves time and reduces the susceptibility to errors. Trumpf’s unloading automation is particularly suitable for companies that produce medium and high quantities, but also for contract manufacturers that process orders of different sizes. Common applications can be found in the furniture industry, in the manufacture of fitness equipment or in the agricultural machinery sector.

Tube process chain fully automated

With unloading automation, Trumpf offers tube processing companies the final link to automate the entire process chain, including laser tube cutting. Some time ago, for example, the company launched a loading automation system on the market to load the raw material directly from the bulk warehouse independently. Users can also automate tube bending or welding with the help of Trumpf. Trumpf also works together with well-known partners from the industry in the tube processing chain. In addition to Starmatik and Transfluid, Stopa is also a member.

Facts & Figures

Trumpf offers manufacturing solutions in the areas of machine tools and laser technology. The company is driving forward the digital networking of the manufacturing industry through consulting, platform and software offerings. Trumpf is one of the technology and market leaders in machine tools for flexible sheet metal processing and in industrial lasers.

In 2022/2023, the company generated sales of 5.4 billion euros with around 18,400 employees. With more than 80 companies, the Group is represented in almost all European countries, in North and South America and in Asia. Production sites are located in Germany, France, the UK, Italy, Austria, Switzerland, Poland, the Czech Republic, the USA, Mexico and China.

Web:

www.Trumpf.com