With the new “Assembly to Nesting” (A2N) technology, IT expert Lantek is launching a tool onto the market that enables sheet metal production to complete in just a few minutes what previously took hours: reading in 3D drawings of individual parts and even complete assemblies with a large number of individual parts, processing them and calculating them for production. In Germany, Lantek is presenting the innovation for the first time at Euroblech in Hanover.

There are a variety of programs and formats for 3D design in sheet metal fabrication – and every company works with a different one. When requesting the production of a three-dimensional part or assembly, sheet metal fabricators must ask their customers to provide the file format they can work with. If this is not possible, they have to break parts down into their individual components, unwind each workpiece, convert it into a 2D format and recognize and define the remaining components such as screws, nuts or washers. To do this, processors draw on tables they have created themselves with bending radii and shortening factors and the expert knowledge they have gathered over the years on material quality, sheet thickness and special features of bending tools.

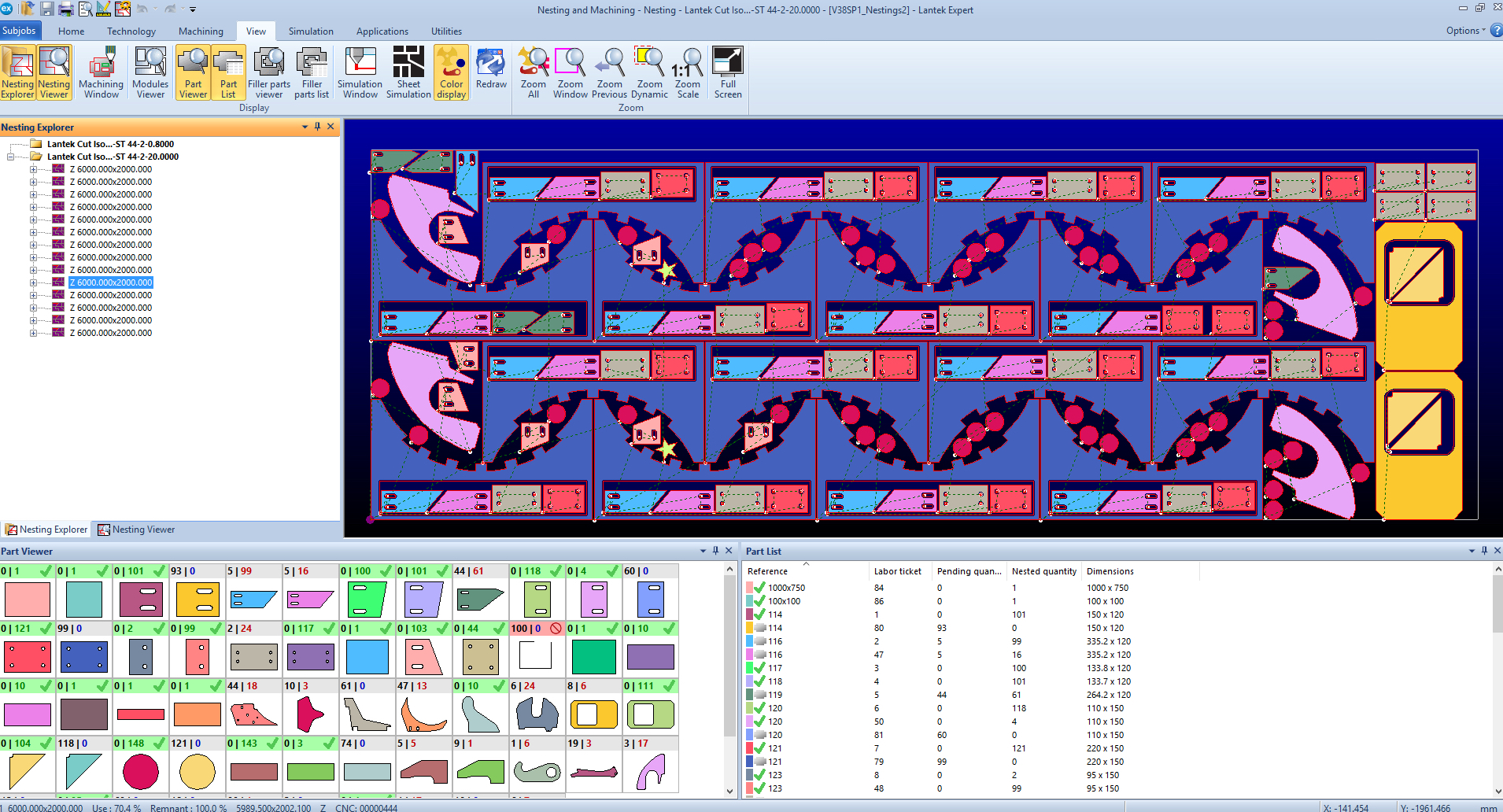

© Lantek

Automatically read, process and calculate 3D file formats

“What sheet metal fabricators need many hours for, Assembly to Nesting does in just a few minutes,” promises Christoph Lenhard, Head of the German Lantek office. With “Assembly to Nesting” (A2N), Lantek customers can now directly import a large number of standard 3D file formats, which then automatically unwinds the parts and converts them into 2D formats for production.

The experts store their individual know-how when installing A2N, which converts it into formulas and applies them automatically in future. However, if the company is already working with Lantek Bend, A2N obtains the necessary information on tools and material reductions during the bending process via the link with the bending software. The cloud-enabled A2N technology can have an impact at different points, depending on the stage of digitalization the company is at and how advanced its Lantek software architecture is.

If the company only uses the 2D and 3D nesting software tools Lantek Expert and Lantek Flex3D, A2N handles the components and imports them there.

If the company uses the Lantek MES Manager software for production management, A2N ensures that complete 3D assemblies are stored there as articles with all components.

If the company even works with the quotation system Lantek Integra Quotes, A2N offers the advantage that the automatically processed assemblies, including all purchased parts, are stored there and can be transferred directly to the quotation.

“For our customers, the technology means a huge time saving, because it is the missing link for the automated production of three-dimensional parts,” says Lenhard.

“And anyone who has heard of it would rather have it yesterday than today.”

Euroblech Hall 11, Stand C08.

Web: www.lantek.com/de