Founded in 1917, Aida was, according to its self-description, the first company in the world to develop and market presses with servo drive (DSF – Direct Servo Former). To date, more than a thousand servo presses have been built.

© Aida

Aida’s servo presses allow the number of forming stages to be reduced while maintaining the same product quality. This is made possible by the soft touch function. Here, the ram movement is slowed down on contact with the material. According to the manufacturer, Aida DSF presses can achieve a significant increase in product quality.

Aida’s energy management system, is based on highly efficient capacitor packs that eliminate the need for energy storage in the flywheel. Load peaks in the forming process can be bridged by the previously stored energy of the capacitors. The mains connection is thus comparable to that of a mechanical press.

All Aida servo presses have servo motors (Aida DSF) specially designed for forming. According to Aida, these are up to five times more powerful than commercially available servo motors.

Aida unveiled the new DSF-NE2 in early 2021. This 2-point servo press features high rigidity thanks to the monoblock frame and high flexibility thanks to the freely programmable servo movement (DSF technology from Aida).

Aida servo motors are installed in the DSF-NE2 presses. These have high torque at low speed, which allows high performance in forming and punching. In order to reduce the deflection under load to less than 0.1 mm/m, all components of the monoblock frame are tested using the FEM method.

The presses of the DSF-NE2 series guarantee low noise and low vibrations thanks to innovative design and state-of-the-art production features in multiple forming with various degrees of forming. This allows production and maintenance cycles to be extended. With up to 120 strokes per minute, this press series stands for absolute top performance, according to Aida. The DSF-NE2 series was awarded Product of the Year in the category “Stamping and Forming Technology” at the Euroblech Awards 2022 in Hanover.

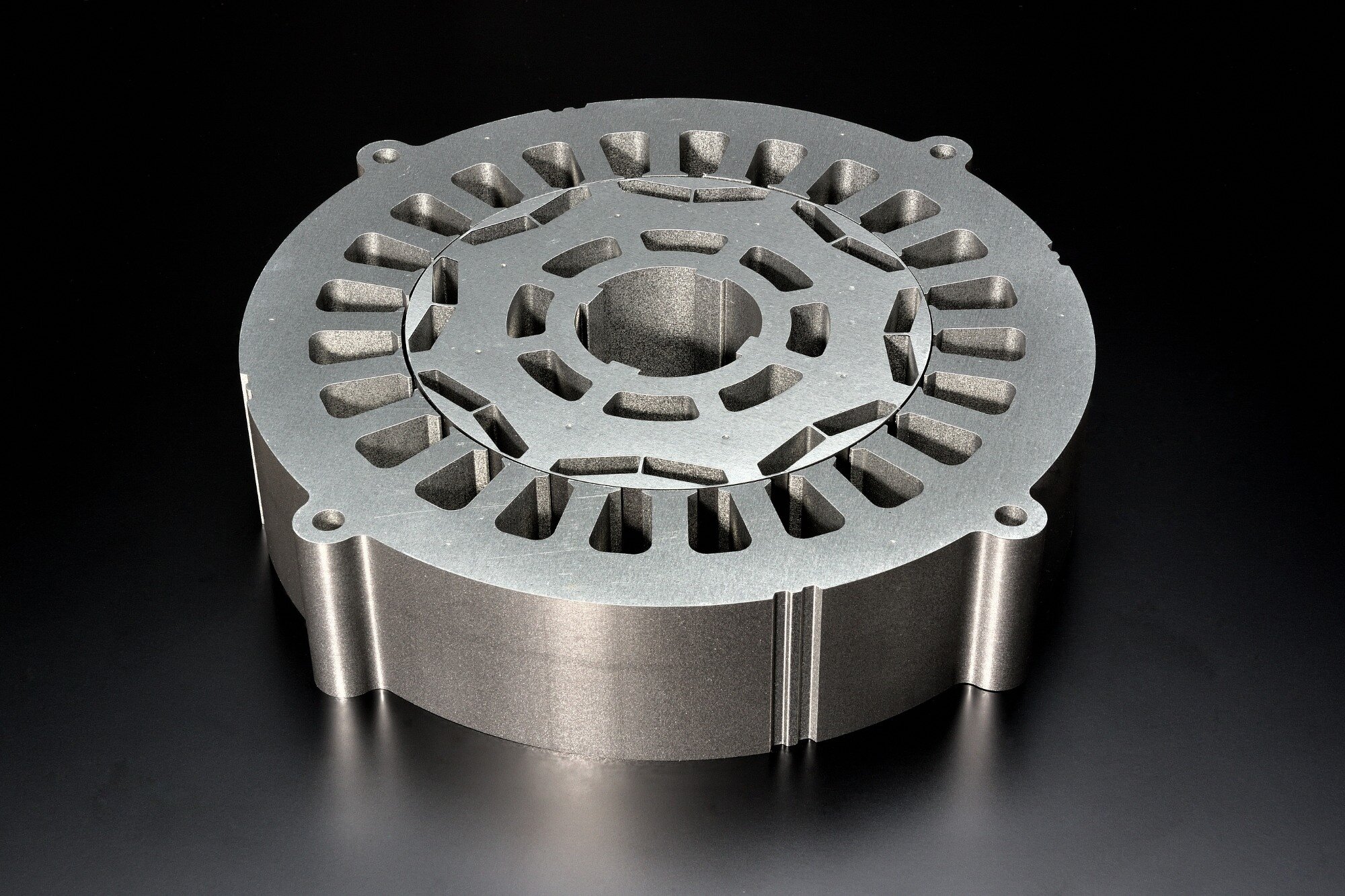

Blechexpo 2023 in Stuttgart is expected to provide visitors with the opportunity to obtain more information about Aida’s DSF-NE2 series. Furthermore, other types of presses such as high-speed presses and precision forming presses will also be presented. The high-speed presses are used in the field of engine core production. Precision forming presses are indispensable for the production of high-tech components for e-mobility, such as bipolar plates for hydrogen-powered cars.

© Aida

For reliable and high-quality production of EV/HEV motors, Aida introduced the MSP series high-speed laminating presses in 2002. The MSP presses, specially developed by Aida, are characterized by accuracy and high rigidity.

To enable two-row production, the high-speed press MSP-3000-370 was launched. Due to its large clamping surface, molds with a size of up to 3700 mm can be clamped. All the precision requirements of the MSP series are also met by the MSP-3000-370. Hundreds of MSP presses have been delivered to customers’ production sites worldwide. Aida’s customers include the most important suppliers to the automotive industry.

At this year’s Blechexpo, the AET Electronic Transfer developed by Aida will be presented. The transfer, developed for the aftermarket, enables the transport of components in multi-stage molds within the press. The AET transfer can be easily retrofitted to all types of presses, regardless of whether the drive is by flywheel or servo. This makes the Aida transfer the optimal solution for integration into existing presses.

Web:

Hall 8 – Booth 8302

www.aida-europe.com