The Hanover-based abrasives manufacturer Vereinigte Schmirgel- und Maschinen-Fabriken AG (VSM) has launched the successor to its Stearat Plus series: VSM Alu-X.

© VSM

With Alu-X, VSM has developed an abrasive series that is specifically aimed at the requirements of grinding non-ferrous metals and thus replaces the familiar VSM Stearat and Stearat Plus series. The abrasive combines two effective VSM technologies in one product: The VSM Ceramics grit technology with continuous self-sharpening is supplemented by the VSM Alu-X active abrasive additional layer for significantly better chip removal.

“Improved chip removal and therefore fewer tool changes, more workpieces per shift and a grease-free workplace: These are the requirements our customers place on abrasives for processing non-ferrous metals such as aluminum,” explains Heiko Schaefer, Product Manager at VSM. “And we are happy to meet these requirements with our Alu-X series.”

“The new Alu-X additional layer significantly reduces chip adhesion and therefore clogging of the abrasive. The ceramic series XF733 and XK733X with Alu-X therefore have increased performance with up to 40 percent more material removal. In addition, there is reduced chip adhesion, which leads to a longer tool life with fewer tool changes,” continues Heiko Schaefer.

Less cleaning, longer sanding

© VSM

Abrasive greases and oils extend the service life of conventional abrasives when it comes to aluminum processing. This is not necessary with Alu-X. The grinding-active additional layer and the semi-open ceramic grit lead to significantly reduced chip adhesion. With Alu-X, the workplace remains grease-free and the extended service life increases the sanding time.

Whether for preparing or removing weld seams, deburring, grinding off sprues, grinding out imperfections as part of repair grinding or to achieve the desired technical surface quality: almost all grinding work with non-ferrous workpieces can be carried out easily with the Alu-X series from VSM.

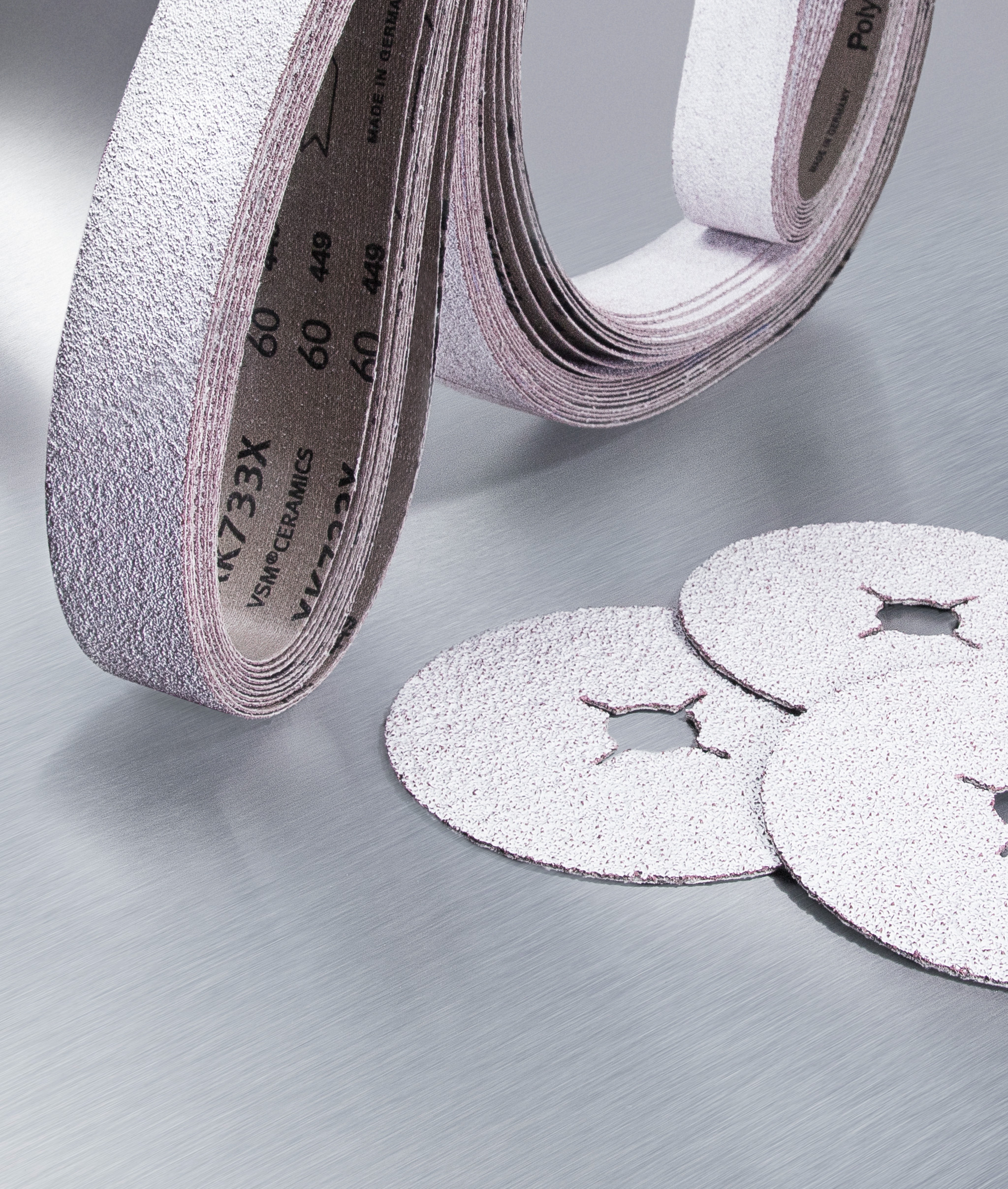

VSM Ceramics with Alu-X is available as fibre disc XF733 in grit sizes 24, 36, 60 and 80: suitable for coarse sanding at low to medium pressure. And as sanding belt XK733X in grit sizes 24, 36, 40, 60, 80 and 120. Optimized for coarse sanding at medium pressure, also suitable for wet sanding.

➢ The VSM aluminum oxide sanding belts KK732X, KK532F and KP532E are also part of the Alu-X series. These products are available in grit sizes from P36 to P600, making them real all-rounders. The abrasive grain produces a matt finish and is particularly recommended for contour processing.

Inhose production makes you flexible

At its headquarters in Hanover, VSM not only develops and produces all abrasives on a flexible backing, but also the ceramic abrasive grains. In-house production of the abrasive grain can have a decisive influence on the performance of the abrasives. With its in-house development department, VSM is also able to improve existing solutions and drive innovation.