At the world’s leading welding and cutting trade fair, Trumpf will be showing a robot for arc welding that calculates its own welding path. This is made possible by a smart sensor that automatically determines the welding spots. The technology counteracts the shortage of skilled workers.

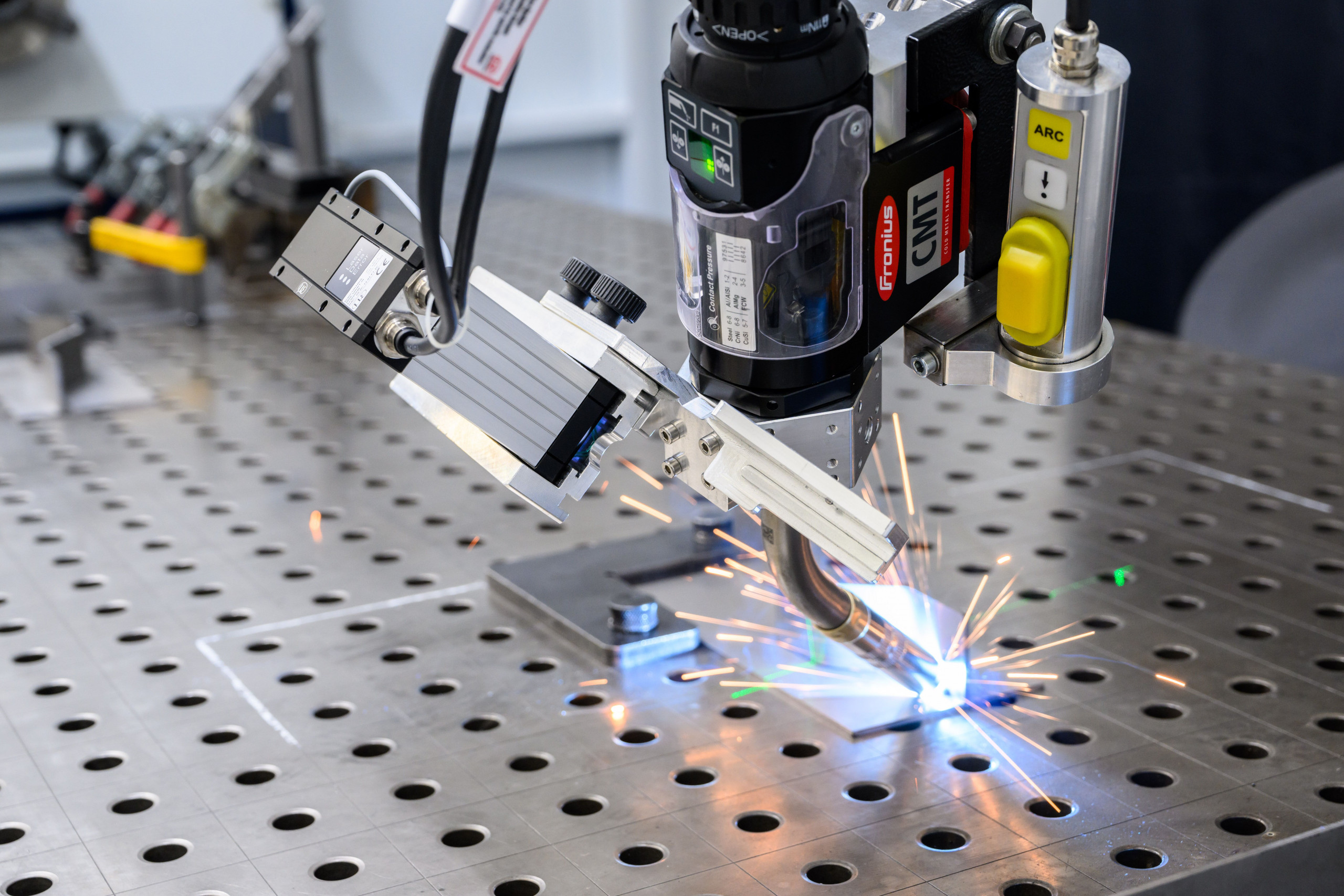

Trumpf is showing a robot that uses sensors to calculate its own welding path at the world’s leading trade fair “Schweissen und Schneiden” in Essen. Responsible for this is the new technology “Smart Seam Tracking”, which the high-tech company has developed together with the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. “With our solution, the welding robot programs itself. This makes it much easier for users to get started with automated arc welding and gives them a competitive edge,” says R&D Manager Sven Klingschat from Trumpf. The sensor is located at the head of the welding torch and automatically determines the welding path for each component.

© Trumpf (Photographer: Martin Stollberg)

Robot is ready to start in a few seconds

If a conventional welding robot is to change direction, the production worker must set a new welding spot in the software each time. This is particularly time-consuming for complex components with many corners or curves. With the Smart Seam Tracking function, the process is much easier. The user only has to bring the welding robot into the start position. The rest is done by the technology. With the help of the sensor, the robot automatically detects the welding path. Meanwhile, the associated software calculates the spot welds without wasting time and creates the welding program for the component. Within seconds, the robot can get started.

The solution makes it much easier for production workers to program the robot. “Even with complex components such as spiral bends, the process takes only a few seconds. What’s more, the employee doesn’t need any specialist knowledge,” says Klingschat. The intuitive user interface can also be used to commission various welding tasks, such as mating layers or identical seams.

Less scrap, more process stability

Smart Seam Tracking saves companies time and money. In addition, they relieve their employees. In addition, process stability increases as the robot automatically corrects its welding path. This allows the solution to better compensate for tolerances or distortions in components. The solution is suitable for any company that wants to increase productivity with the help of automation. Users who weld large and complex components benefit in particular. Since the weld track adapts individually to each component, companies achieve consistently high quality. Parts for wind power or screw conveyors for the animal feed industry, for example, can be manufactured without any problems. Trumpf is launching the solution for its TruArc Weld 1000 arc welding machine. Users who already own a TruArc Weld can retrofit it.

Facts & Figures

The high-tech company Trumpf offers manufacturing solutions in the fields of machine tools and laser technology. The company is driving forward the digital networking of the manufacturing industry through consulting, platform and software offerings. Trumpf is one of the technology and market leaders in machine tools for flexible sheet metal processing and in industrial lasers.

In 2022/23, according to preliminary figures, the company generated sales of 5.4 billion euros with around 17,900 employees. With more than 90 companies, the Group is represented in almost all European countries, in North and South America, and in Asia. Production sites are located in Germany, France, Great Britain, Italy, Austria and Switzerland, in Poland, the Czech Republic, the USA, Mexico and China.

Web:

www.trumpf.com