With the appointment of Andreas Bügener as the second managing director, the next generation is also moving up in the management of the blast machine manufacturer Agtos.

In the presence of the shareholders and the staff of the headquarters in Emsdetten, Managing Director Antonius Heitmann introduced Mr. Bügener as the second man at the top during a works meeting.

This gives customers, suppliers and other business partners of Agtos the confidence to continue the forward-looking and close cooperation.

The mechanical engineering company, founded in 2001, has already been preparing for the future for several years. Initially, investments were made in the buildings at the headquarters in Emsdetten and in the production plant in the Polish town of Konin. Then an ERP system was introduced that spanned both locations. The associated process changes necessitated personnel changes among employees and some department heads. Thus, the appointment of Andreas Bügener as Managing Director is the logical next step.

Andreas Bügener, who comes from the region, values common goals on which everyone can work together effectively. He has a technical background and several years of sales and project experience. Previously, he was managing director of the Belgian subsidiary of a larger, international group of companies.

Right at the beginning, he emphasizes that he considers the topics of digitalization, sustainability and customer loyalty essential for a successful future for Agtos. This means that the successful development of Agtos can continue.

Competence in blast wheel technology

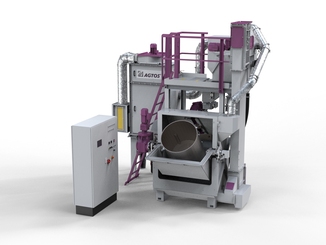

Agtos has been on the market for over twenty years. Around 160 employees work at the two sites. In Emsdetten, the company’s headquarters, the concept development as well as the design of the shot blast machines takes place. Production is located in the Polish town of Konin near Poznań.

Shot blast machines are used for cleaning, derusting, roughening, solidifying and finishing (optical enhancement) of surfaces. Predominantly, workpieces made of metal are processed, but the blasting effect can also be used for concrete and plastic parts. The size and weights of the parts to be machined vary greatly. Therefore, the machines are often adapted to the specific requirements or specially developed for this purpose.

The constant focus on customer requirements has resulted in the company being regarded as a specialist in the design and manufacture of shot blast machines, especially for foundries, even beyond the region. Therefore, customers on all five continents work with blasting machines from Agtos.

In addition to new wheel blast machines, Agtos offers used blast machines. This is advantageous for companies that need a shot blast machine at very short notice or use it only temporarily.

The abrasive used in the wheel blast machines does not only act on the workpiece surfaces. The abrasive effect is also noticeable in the blast machines. Therefore, service, i.e. stocking and delivery as well as installation of spare and wear parts, plays a major role. In addition, maintenance, repair and modernization work is also carried out on machines from other manufacturers. These are always carried out by experienced professionals.

Web:

www.agtos.de