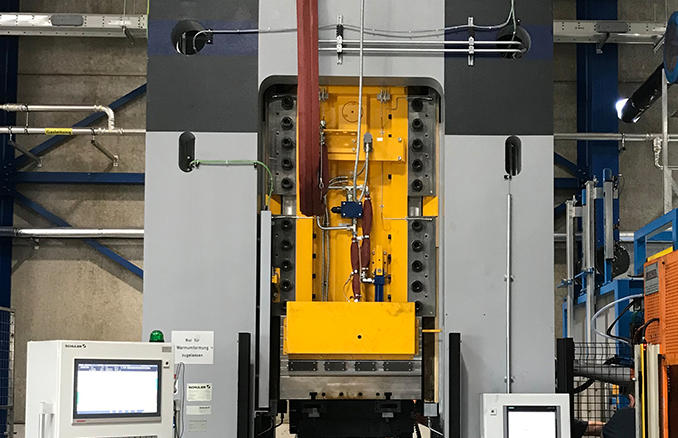

Kaiser Aluminium-Umformtechnik GmbH, based in Fluorn-Winzeln and Dunningen-Seedorf, is regarded as a leading German manufacturer of forged aluminium components for small and medium-sized series. Now the company from the Black Forest has successfully commissioned its first servo screw press from Schuler. On the PAR 360 SDT system, highly complex chassis components for the automotive industry are produced in semi-automatic operation.

“With this investment, we are further expanding our market position as a competent partner for forged parts and components in the aluminum sector,” expects Managing Director Thomas Kaiser. “The installation of the press at our new location in neighbouring Dunningen-Seedorf should also be seen as an investment in the region and the country.”

Schuler now uses only servo motors instead of the previous squirrel-cage drives in its screw press series. The advantages are a lower machine height and improved drive controllability as well as higher starting torques with shortened stroke cycle times. In addition, working with full working capacity at reduced lifting heights becomes possible. A closed water cooling circuit for the servo motors replaces the previous cooling system with fresh air supply from outside and leads to an optimized temperature stability of the drive system independent of operational air conditions.

Background

Schuler offers customer-specific technology in all areas of forming technology – from networked presses to press shop planning. In addition to presses, the product portfolio also includes automation and software solutions, tools, process know-how and service for the entire metalworking industry. Customers include automotive manufacturers and suppliers as well as companies from the forging, household appliance and electrical industries. Presses from the Schuler Group mint coins for more than 180 countries. As a provider of innovative system solutions, we support our customers worldwide in the digital transformation of forming technology. In fiscal year 2019, Schuler generated sales of 1.136 billion euros. Schuler AG, founded in 1839 at its headquarters in Göppingen (Germany), is represented by approximately 6,000 employees at production locations in Europe, China and America as well as service companies in over 40 countries. The majority of the company is owned by the Austrian Andritz Group.