Things had to move quickly at the Swabian company Gebr. A major order for the production of around half a million sheet metal parts per year called for a top-class production technology solution. Together with Yaskawa Europe, the company set about implementing a production cell.

© Yaskawa Europe GmbH

The Swabian automotive supplier Gebr. Binder enjoys an excellent reputation in the industry. The family-owned company based in Neenstetten is considered reliable, customer-oriented, innovative and supplies OEMs all over the world. With around 800 employees, the company is dedicated to forming technology and sheet metal processing. The fact that a major German car manufacturer approached the company, which has expanded rapidly in the past, with an order for the series production of a sheet metal construction to accommodate the on-board batteries of certain vehicle series speaks volumes for the company’s reputation and performance.

Thomas Pflüger, mechanical engineer and head of the joining technology department at Binder: “To be able to handle an order of this size – the maximum production output is around half a million battery frames per year – it was clear that it would not be possible without investing in a completely new, highly automated system that integrates the necessary spot welding, testing, marking and handling processes.”

One operator, two robots, three stations

The Binder engineers immediately set to work on an initial rough draft that conceptually outlined the main stations of the new robot cell. This concept formed the basis for Yaskawa Europe, whose specialists were entrusted with the detailed planning and realization of the

complete system.

Roland Hermann, Senior Key Account Manager at Yaskawa, recalls: “It was clear to all of us that we would only be able to achieve the cycle time specifications for this large series part by using two six-axis robots, one for spot welding and another for complete handling. In addition, a three-station solution was recommended, which allows all processes to be implemented in parallel and therefore with neutral cycle times. While parts are inserted manually at the first station, they can be welded at station two and checked and removed at station three.”

© Yaskawa Europe GmbH

Sophisticated solution with impressive details

If you look at the recently commissioned system, it impresses with a whole host of well thought-out details, but also with a very small footprint. Of course, every component was selected with maximum performance and reliability in mind.

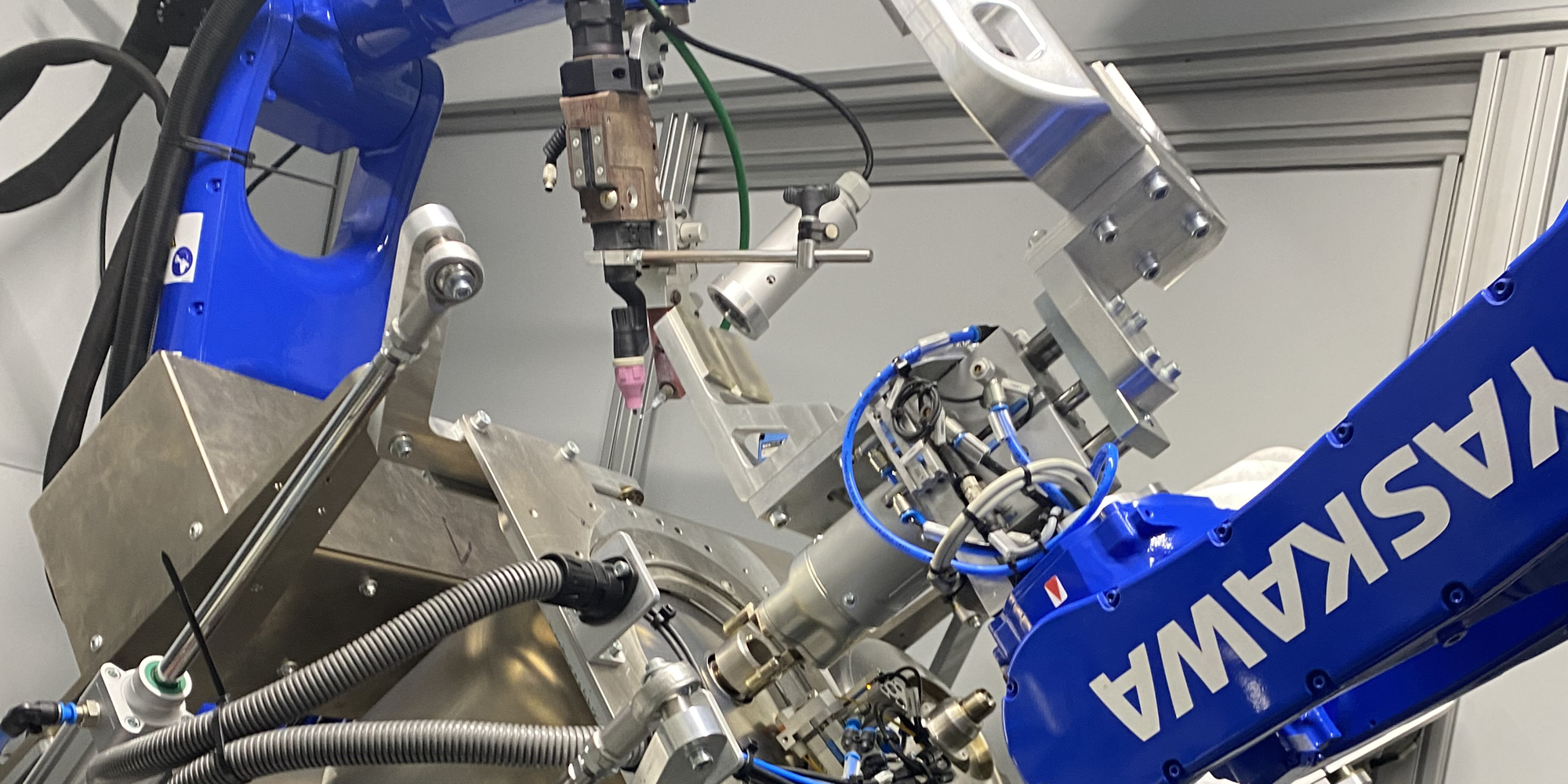

This starts with the robots: Spot welding is performed by a slim Motoman six-axis robot from the powerful SP series, while a fast and equally precise GP88 is responsible for the handling processes. Thomas Pflüger comments: “There was no great need for discussion when it came to selecting the robots. We already have several Yaskawa robots in use and know that the “Motomänner” meet our requirements one hundred percent. They are highly reliable endurance runners that master every production marathon with flying colors.”

Trimmed for maximum availability

All other components should also keep availability high thanks to their quality. The components in use include a lightweight servo welding gun, an automatic cleaning and changing station for the electrode caps, a 2D camera system from Cognex for quality assurance, a class 1 marking laser from Trumpf, a Siemens PLC and, of course, a state-of-the-art welding controller from Bosch Rexroth with permanent monitoring of the welding parameters.

A highlight of the system is the 3-station vertical positioner, which is equipped with two fixture nests per station, i.e. for the parallel processing of six battery frames. Roland Hermann: “The special feature here is that this solution is based on a Yaskawa standard product, the R-1000 positioner, which has a vertical rotary axis. We have equipped this modular basic drive with a base plate designed for the automatic devices and implemented the three-station solution on it. The 120 degree rotation required for the application is implemented purely by software during operation. The positioner axis is integrated into the master controller of the robots as a fully-fledged robot axis.”

© Yaskawa Europe GmbH

Briefly outlined: the workflow in the cell

The sheet steel construction to be welded, which comes from the in-house forming technology, consists of two individual parts, the larger battery frame and a smaller holding plate. An operator inserts the two parts into the first fixture nest and repeats this process for the second nest. Once the operator has left the safety area, the clamping device automatically secures the parts and moves the table on to station two.

Here, the Motoman spot welding robot from the SP series sets a total of eight welding points per component, five to fix the frame and three to attach the retaining plate. “It is impressive to see the precision and dynamics with which the welding robot works and how well thought-out the programming has to be in order to be able to approach the welding points within the narrow sheet steel construction with the large servo gun. It’s really millimeter work here,” says Thomas Pflüger.

Cycle time determining: Cleaning and changing the electrode caps

The condition of the electrode caps is of course decisive for the process. The regular cleaning of the caps by milling off the resulting zinc layer as well as the replacement after a certain number of milling processes are carried out fully automatically at the station without any intervention by the operator. As this process is one of the processes that determines the cycle time, the robot was positioned with the shortest possible travel paths in mind when positioning the cleaning and changing station.

Once spot welding is complete, the positioner cycles through another 120 degrees to station three. Here, the presence and correct position of grub screws and a nut are checked using a camera while still in the fixture. After a successful QA check, the slim Motoman GP88 simultaneously removes the two components with its pneumatic double gripper and moves to the laser marking station, where the components are given a numerical letter code for identification and part traceability.

There was no need for special additional laser protection devices when implementing the marking process, as the components are guided to the marking head by the handling robot in a laser-safe manner. This is achieved by the robot applying predefined pressure to the sealing elements of the marking head, thus meeting the laser safety requirements. In the final step, the six-axis robot places the I.O. parts on a conveyor belt, which is unloaded manually. The handling robot places components that are declared as not OK by either the camera or the welding control system in a separate box that is monitored for the number of pieces.

The entire system is controlled by a higher-level Siemens S7 PLC with visualization, to which the two Yaskawa YRC 1000 robot controllers are connected via Profinet. The system has been running smoothly on both the software and hardware side since it was commissioned. The decision in favor of Yaskawa has therefore never been regretted at Binder.

Web:

www.yaskawa.de