Anyone who wants to cut rolled ingots and plates precisely and reliably to the desired length needs the right sawing technology – and so does the construction and tool steel specialist JKZ Bučovice. The Czech steel trader and machining service provider relies on Kastobbs block band saws for this purpose: The power packs impress with high precision and smooth running and can easily cope with large dimensions and heavy workpieces.

© Kasto

Structural and tool steels are the specialty of JKZ Bučovice, a.s. – and in a wide variety of geometries, grades and dimensions. Founded in 2000 in Bučovice, Czech Republic, some 40 kilometers east of Brno, the company is one of the country’s leading service providers for toolmaking. In addition to numerous customers in the Czech Republic, JKZ also delivers to Slovakia, Poland, Austria, Germany, Slovenia, Hungary, Romania and the Baltic States, among others. 125 employees generate sales of around 20 million euros a year. The company permanently stocks around 10,000 tons of steel on a storage area of 15,000 square meters.

In addition to a wide variety of materials, a broad processing spectrum is also crucial to JKZ’s success. The portfolio includes various technologies such as flame and plasma cutting, grinding and deep hole drilling. A machine park with a total of 20 three- and five-axis machining centers makes it possible to reliably prepare even large workpieces with dimensions of up to 2.5 x 4.5 meters according to the customer’s wishes. The first station for most raw materials, however, is the sawmill: an impressive 35 automatic bandsaws in all dimensions are ready here to cut the required steels precisely and efficiently to the appropriate length.

Proven supplier for sawing and storage technology

For many years now, JKZ has relied on the sawing machines of Kasto Maschinenbau GmbH & Co KG from Achern in Baden. The oldest models have been in use for almost 20 years – and still reliably fulfill their purpose. In addition, a Kasto UNITOP 5.0 transfer storage system has enabled the automated and compact storage of 5,000 tons of long metal goods at the site since 2015.

“This not only enabled us to optimize our material flow and delight our customers with shorter delivery times and a lower error rate, but also to create additional space for further processing machines,” explains Managing Director Marek Hermann. “This was an important point for us because the demand for machined material is steadily increasing at the companies we supply.”

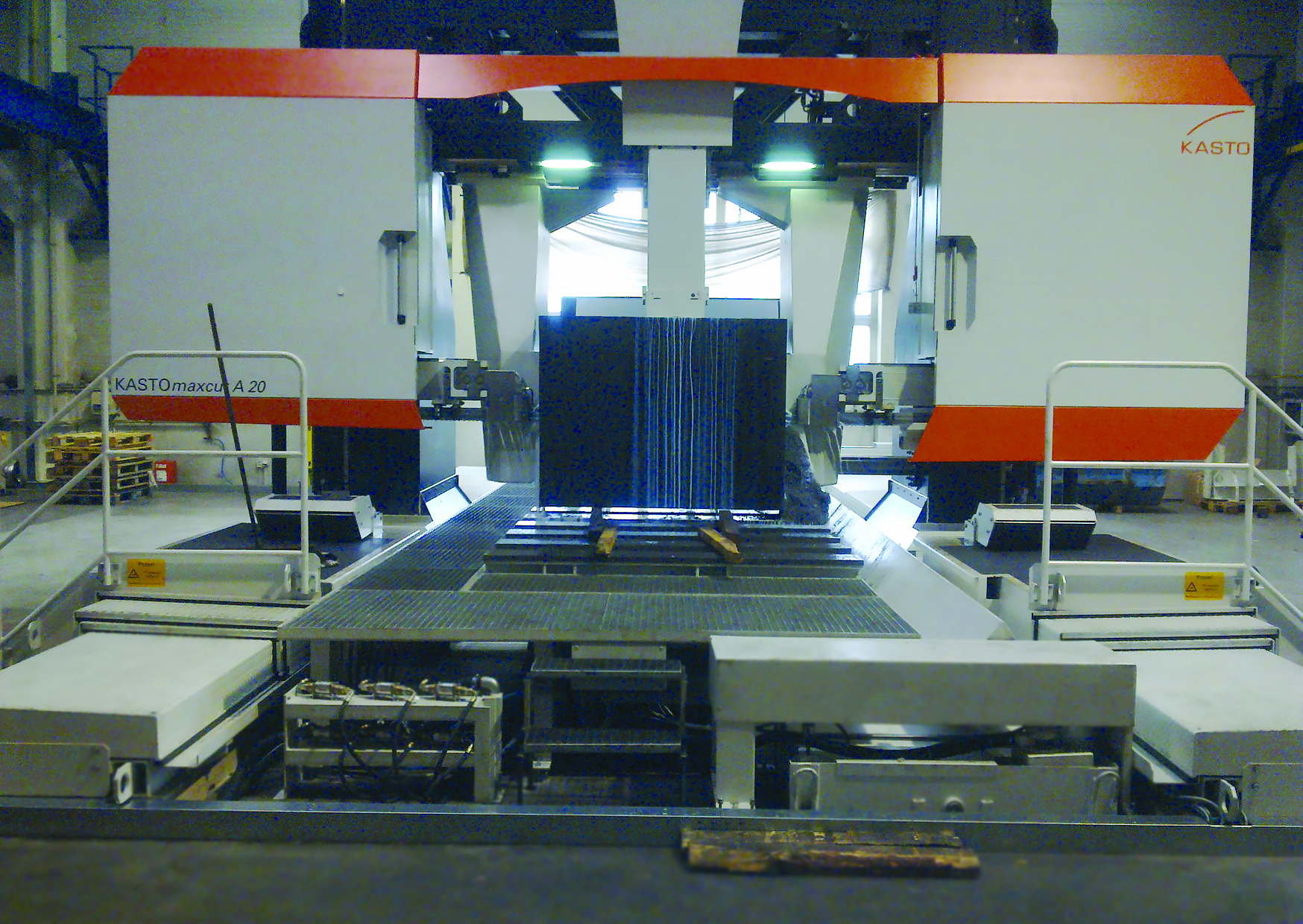

JKZ used the gained space, among other things, for the purchase of two new fully automatic log band saws of the type Kastobbs A 3×20. These giants are specially designed to make up different cross-section dimensions from rolled blocks and plates, square or flat materials. They can handle cutting heights of up to 420 millimeters and cutting lengths of up to 7,000 millimeters. The load-bearing capacity of the material support table is an impressive 56 t. This makes the Kastobbs a real powerhouse that can easily handle even large dimensions and heavy workpieces.

© Kasto

Additional capacities for machining large parts

“We have already had extremely positive experience with two older models of the same series,” Hermann reports. “The two machines purchased in 2006 and 2007 are still serving us very well today. And since there are only a few competitors who are equipped to machine large parts like we are, we decided to further expand our capacity here in order to be able to serve the high demand even better.” The demands of the customers are not without their own: in addition to the constant availability of numerous materials and short delivery times, toolmaking also requires particularly high quality and precision of the machined workpieces.

Thanks to the additional reinforcement of the machine park, however, JKZ can cope with this perfectly. “The Kastobbs saws are very robust and reliable, and on top of that they work extremely accurately,” finds Managing Director Hermann. Characteristic of the series is the long-cutting work. The saw unit travels on rails with hardened and ground rollers arranged on the sides. The workpiece remains fixed on the saw table. “This makes the machines particularly space-saving compared to other models,” clarifies Hermann. The Kastobbs’ torsion-resistant welded construction ensures tool life as well as high precision.

Flexible to use and easy to operate

© Kasto

The electronically controlled saw feed can be optimally adjusted by the employees at JKZ to the material quality and the cross-section of the material to be sawn. The speed of the saw band is also infinitely variable. “This makes the band saws flexibly suitable for a wide range of tasks,” says Marek Hermann happily. All display and operating elements of the Kastobbs are located on a control panel that travels with the machine. This ensures maximum overview, an unobstructed view of the workpiece and safe control of the cutting process.

Another useful feature of the fully automatic Kastobbs A is the 0°/90° belt twist. “This enables us to saw workpieces in both longitudinal and transverse directions,” Hermann explains. “This enables unmanned operation from complete block to finished cut workpiece.” Of course, it is also an advantage that the sawing and storage technology come from the same manufacturer: “All components harmonize smoothly and are networked with each other and with our ERP system via well-functioning interfaces,” explains the managing director. “This ensures an efficient flow of materials from incoming goods to shipping.”

Products and service are equally convincing

Those responsible at JKZ Bučovice are completely satisfied with the cooperation with Kasto. “From joint planning to installation and commissioning to maintenance and servicing: Kasto’s service is really competent and always has an open ear for our individual questions or requests,” describes a happy Marek Hermann. “We are very happy to have such a reliable partner who knows the challenges of the steel trade inside out and supports us in meeting them with innovative, functional and future-proof solutions.”

Web:

www.kasto.com