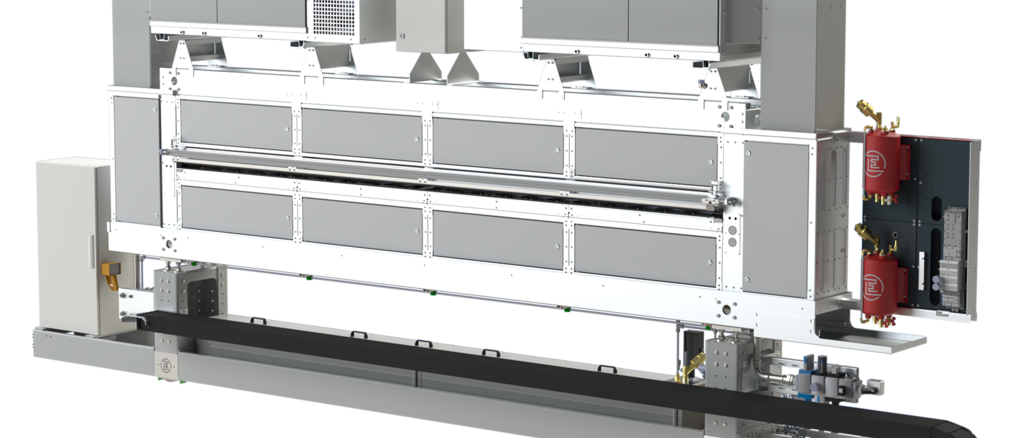

At Euroblech, Eckardt will be showing a large spray oiler from the EQS series for the first time. The machine is designed for strip widths of up to 4100 mm and, thanks to its streamlined design, can be integrated into existing process lines in a versatile manner. In addition, Eckardt will present a selection of its smaller roller and spray systems. Integrated dosing solutions round off the panorama.

EQS stands for Eckardt Quality Spraying and is a further development of the EOS large-scale spraying systems. In particular, customer requirements in terms of compactness and flexibility have been incorporated into the machine update, which focuses on the following aspects:

Precise integration: The modular design and shortened overall length provide the prerequisites for uncomplicated integration into the existing installation space and thus make the machine particularly attractive for retrofitting requirements.

➢ Improved occupational/environmental protection: The release of oil mist into the ambient air is reduced to a maximum via a multi-stage filter system. Significantly longer filter service lives – pre-filtering already in the extraction section, extraction at the bottom/top – increase cost-effectiveness in operation.

➢ Minimal maintenance effort: Improved accessibility to all areas allows maintenance work to be tackled without cumbersome handling. By optimizing details at many points in the design (including flanged nozzles), the maintenance intervals can be stretched overall.

➢ Flexible control integration: The EQS spray oiler can be integrated into many common control systems: Siemens S7, Siemens TIA Portal, Allen Bradley, Beckhoff, Bosch Rexroth …

Roller and spray oiler for smaller formats

There is also room for the smaller oiling formats at the Eckardt booth. On display is a selection of roller systems from the WF series, where the oiling rollers are adjusted either by springs or pneumatic lifting cylinders. EOS 1 series spray systems are also on the starting line. This allows strips and blanks to be oiled on both sides over the entire surface or on selected strips.

Metering solutions for wall and floor mounting

Eckardt’s EDS dosing systems are another focal point of the trade show presentation. These are complete systems – pressure vessels, valves/feed lines, dedicated dosing control – for wall or floor mounting. Its modular basic design offers practically unlimited options for the arrangement of components and enables precise integration under the respective spatial and process-related conditions.

Background

Eckardt Systems, founded in 1992, is a manufacturer of oiling systems and cleaning and preservation equipment for industrial production. The company is family-run in the second generation and employs around 30 people. The product range includes roller oilers, squeeze-on oilers and spray systems, which are available in several versions for different material widths In addition, there are oil mist separators as well as complete systems according to customer-specific requirements. In addition, Eckardt offers a wide range of high-performance spray and spit nozzles and metering systems, as well as lubricants and oils under its own ROTOL brand.

Euroblech Hall 27, Booth G156