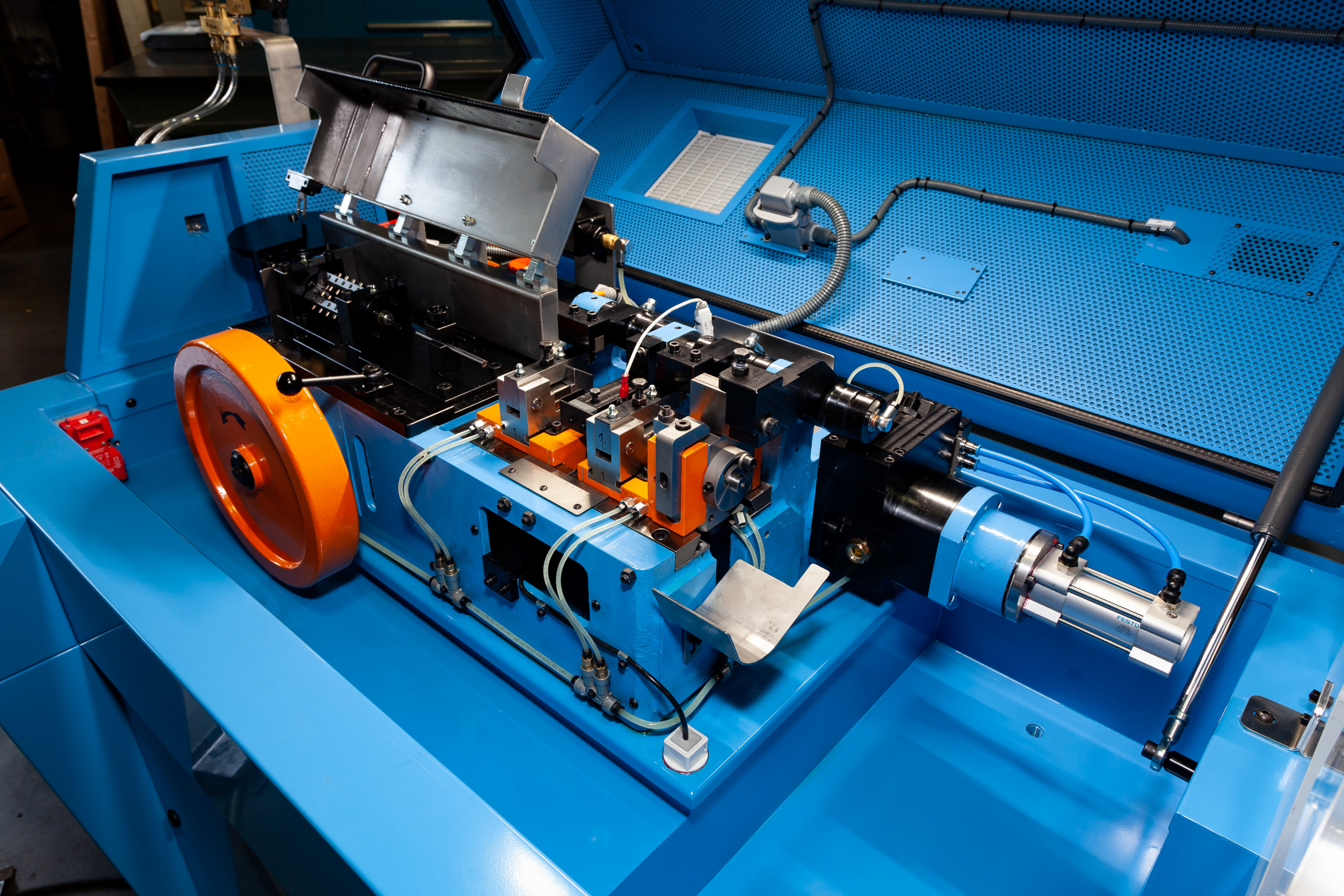

At Interwire, Jouhsen-Bündgens presented the benefits of the latest generation of its UD0. It offers an efficient solution for rotary straightening and precise cutting of thin and long sections from a wide variety of materials. The PrecisionCut UD0 is Jouhsen-Bündgens’ answer to the increasing demands on wire processing, which are fully met by this combined straightening and cutting machine.

The UD0 is suitable for straightening and cutting wires made from a wide variety of materials such as carbon steels, titanium alloys, stainless steels, nickel-based alloys, cobalt-based alloys, bronzes, nickel silver, heat conductor alloys, nitinol, etc. “It is even possible to process carrier wires with metallic coatings, such as gold,” says Dr. Peter Renz, Managing Director of Jouhsen-Bündgens Maschinenbau GmbH. This is made possible by the flexibility to use different straightening bodies depending on the sensitivity and desired surface and, if necessary, to straighten using liquids.

Best results even with thin and long sections

An optionally available driven support keeps thin, long sections absolutely straight. It is available in lengths of 1 meter, 1.5 meters or 2 meters. The stacker picks up the straightened wires and transports them further. Depending on the requirements profile, socket-socket or socket-knife cutting is available for the precise cutting of wire or tube sections, so that even extremely thin wires can be cut to length without any problems and to a high quality.

Web:

www.jouhsen.de