The specialists from Jouhsen-Bündgens will be providing information at Wire (Hall 11, Stand G51 ) about the PrecisionGrind PG3 and PrecisionGrind PG11 needle grinding machines for grinding on particularly short sections. Also on display will be the PrecisionCut UD0, a straightening and cutting machine for particularly thin wires.

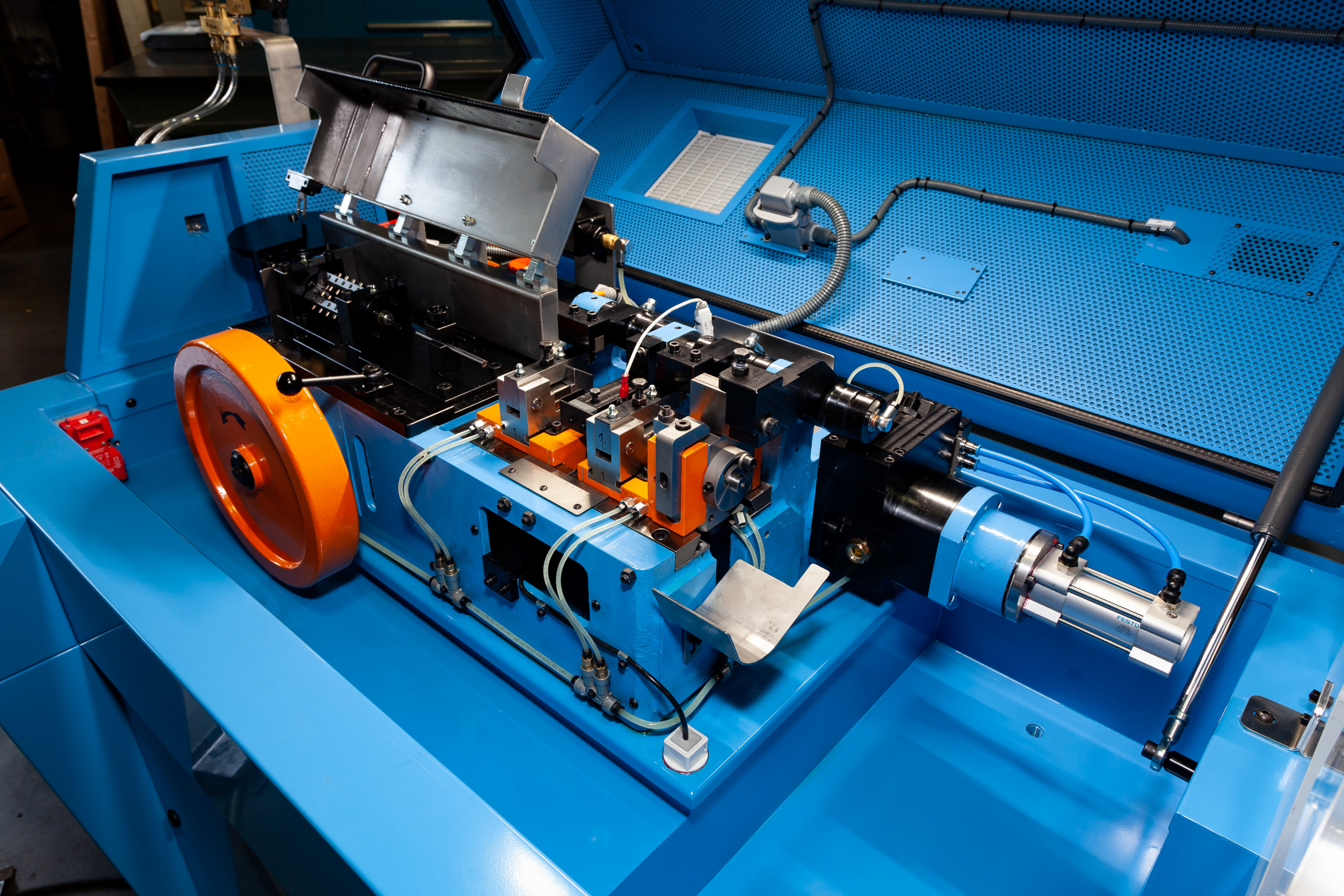

“When it came to center grinding sections smaller than 35 mm, proven center grinding machines had previously reached their limits,” says Managing Director Dr. Peter Renz, describing the challenge. Shorter needles were therefore shortened to the desired size after grinding the tip. The two needle grinding machines PG3 and PG 11 provide a remedy: They are designed so that sections from a length of 20 mm and a diameter of 0.25 to 2.50 mm can be machined.

© Jouhsen-Bündgens

Saves time, material and personnel

The short blanks are separated and positioned from the magazine by a grooved conveyor wheel. A transport unit conveys them along the grindstone. Says Dr. Renz, “It’s this particular design feature that allows for short section guidance.” Those who use PG 3 or PG 11 for grinding the tips of short sections therefore benefit from time and material savings. Both needle grinding machines operate with a magazine system for part supply and removal. While the sections are processed from a magazine, no operators are required. Only the change of magazines is performed manually. This reduces manpower requirements and thus improves the cost-effectiveness of center grinding.

Precisely adjustable grinding process

Both machines allow grinding of concentric tip shapes (convex, concave or even straight) on sections of different diameters. The length and shape of the tips as well as the machine output are precisely adjustable via motorized adjustments in the x,y and z axes. The needle grinding machines PG3 and PG11 are suitable for a wide range of products. Typical examples are needles used in the medical field. However, the spectrum ranges from fishing hooks to perforating tips for thin films or sheets for lithium-ion batteries.

Flexible and secure solution

Wherever short needles with a part length of 20 mm to a maximum of 80 mm – or even 140 mm depending on the tip shape – are required, these two center grinding machines provide an efficient solution. A closed machine housing makes them particularly safe and yet easily accessible from all sides. Drive and electronics are integrated.

© Jouhsen-Bündgens

Experience live

“Our trade show team is looking forward to explaining to visitors the benefits of the machines in our broad portfolio,” said Dr. Renz. A special highlight for him is finally being able to present the PrecisionCut UD0 straightening and cutting machine at the booth. The UD0 is particularly convincing for applications in the medical sector, as it is suitable for straightening and cutting wires with a diameter of 0.05 to 1.5 mm as well as sections from 3 to a maximum of 3,000 mm in length.

Web:

www.jouhsen.de