The Schröder Group exhibited a wide range of sheet metal working machines at Stand 1805 in Hall 1 of Blechexpo. The presentation will focus on swivel bending machines for all sheet thicknesses and automation solutions for a wide range of applications. Highlights include the MAK 4 Evolution UD, which bends 6 mm thick sheets to a width of 3200 mm, the PowerBend Multi with the option of conical bending, and the brand new EVO DuoBend, a swivel bending machine with two bending beams.

The top model in the range of industrial swing bending machines is the MAK 4 Evolution UD for sheets up to 6 mm thick. The equipment of the machine with its generous upper beam stroke of 1090 mm includes up-and-down bending beam and suction plate stop. As a special function of the POS 3000 3D graphic control, Radius Step Bending will be shown.

The EVO DuoBend makes its first public appearance. This motorized swing bending machine (useful length 4000 mm, sheet thickness 4.0 mm) works with two independently operated bending beams. After the up-and-down bending press, Schröder thus introduces a second possibility for manufacturing large-area products with counterbends without having to turn the sheet. Bending of a negative bend is performed by the upper bending beam and bending of a positive bend is performed by the lower bending beam. This eliminates the need to bypass already bent product legs, which means that there are no longer any restrictions due to the maximum bypass radius of less than 200 mm. The EVO DuoBend will appear at Blechexpo with a fully automatic tool changer, as has proven itself in practice on the MAK 4 Evolution UD with molds up to 500 mm high as a great relief during setup. Hans Schröder Maschinenbau GmbH has been nominated for the innovation award “Blechexpo best-Award 2023” with the EVO DuoBend.

© Schröder Group

Rotatable upper beam

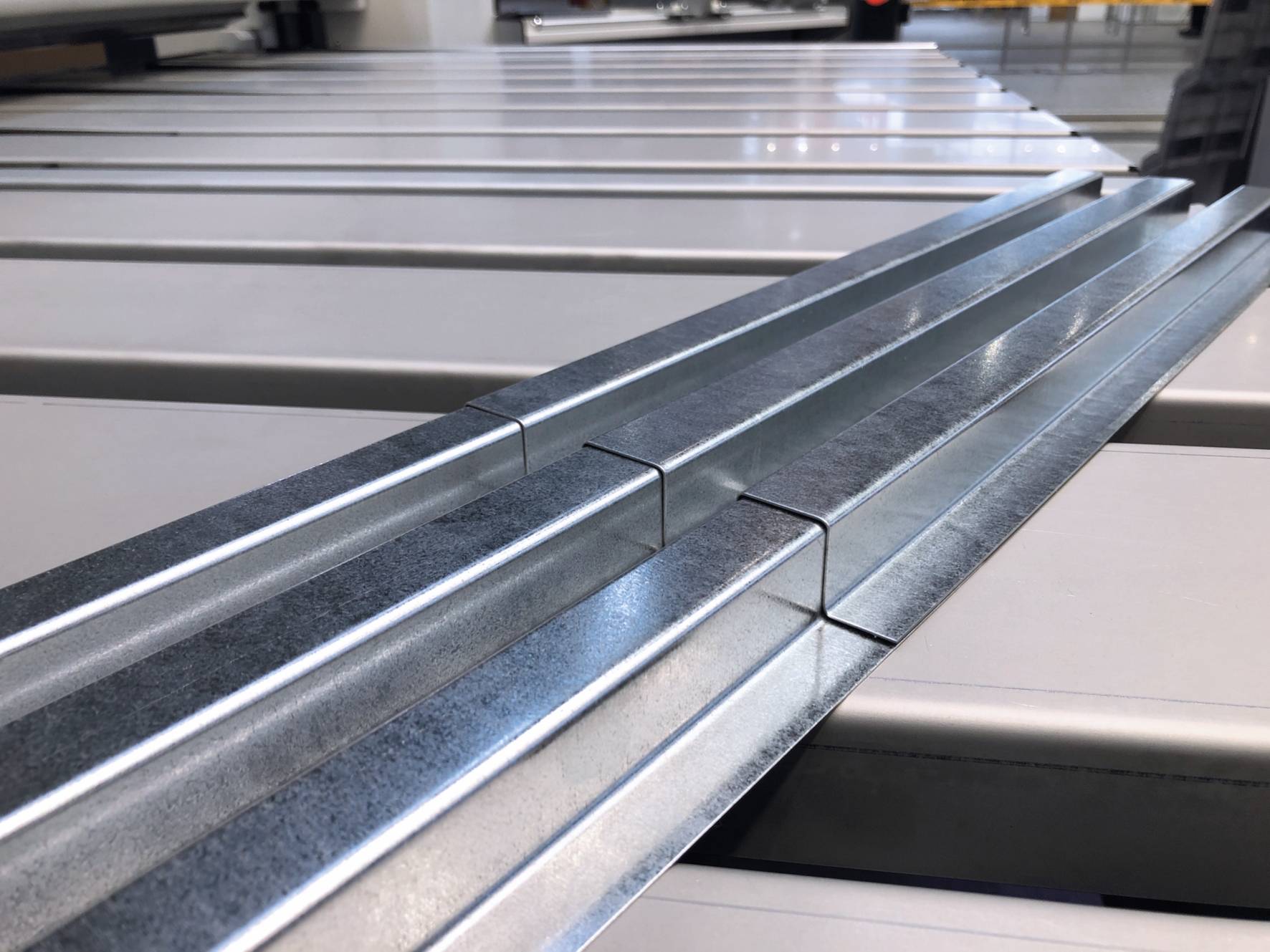

With the option of the rotatable upper beam, the Schröder Group offers the possibility to quickly switch between tool stations and geometries with different clearances. Both the PowerBend Professional and the PowerBend Multi will be shown at the show with improved rotating top cheeks. The PowerBend Multi also features a new squeeze function that allows hollow envelopes to be produced entirely by bending with the bending beam. The swivel range of the bending beam was extended to 190° for this purpose. In a very short time, the following stop variant has also become an insider tip among the machine options of the PowerBend Multi: conical bending. With the unique two-axis backgauge, form-fit plug-in profiles can be produced quickly and easily with precision in the tenth of a millimeter range. This eliminates the need for manual finishing in applications where edges are not parallel, such as parapet or wall copings, roof edge flashings, verge flashings, and claddings that are to have a slope.

Perfect radii

Also on display at Blechexpo are the round bending machines of the Schröder-Fasti brand. These are especially appreciated for roll geometry with a crown that allows particularly uniform radii. Beading and flanging machines are also on the stand, as are the ASK 3 manual press brake segmented on all cheeks and the two powerful MHSU and PDC motorized guillotine shears with NC positioning stop.

Background

The Schröder Group consists of Hans Schröder Maschinenbau GmbH based in Wessobrunn-Forst, Schröder-Fasti Technologie GmbH based in Wermelskirchen and SMU GmbH based in Leinburg-Weißenbrunn.

Founded in 1949, Hans Schröder Maschinenbau GmbH combines tradition and modernity in mechanical engineering: Successfully managed as a quality and customer-oriented family business, Hans Schröder Maschinenbau specializes in the development of modern machine concepts for bending and cutting sheet metal.

Through the integration of Fasti-Werke in 2006 and with a worldwide presence, the Schröder Group is now one of the leading suppliers of machines for swing bending, cutting, beading, flanging and round bending of all types of sheet metal. The variety of precision machines ranges from proven solutions for the craft to innovative high-performance machines for automatic industrial production. In 2021, the Schröder Group was expanded to include the tool manufacturer SMU GmbH. Today, the Schröder Group employs a total of more than 300 people at various locations in Germany and abroad.