The MHSU motorized guillotine shear is a proven classic from Hans Schröder Maschinenbau GmbH. The machine has now been overhauled. The most important innovation is a patented sheet holding device that increases handling flexibility. In addition, sheets can now be processed from the coil.

Schröder Group

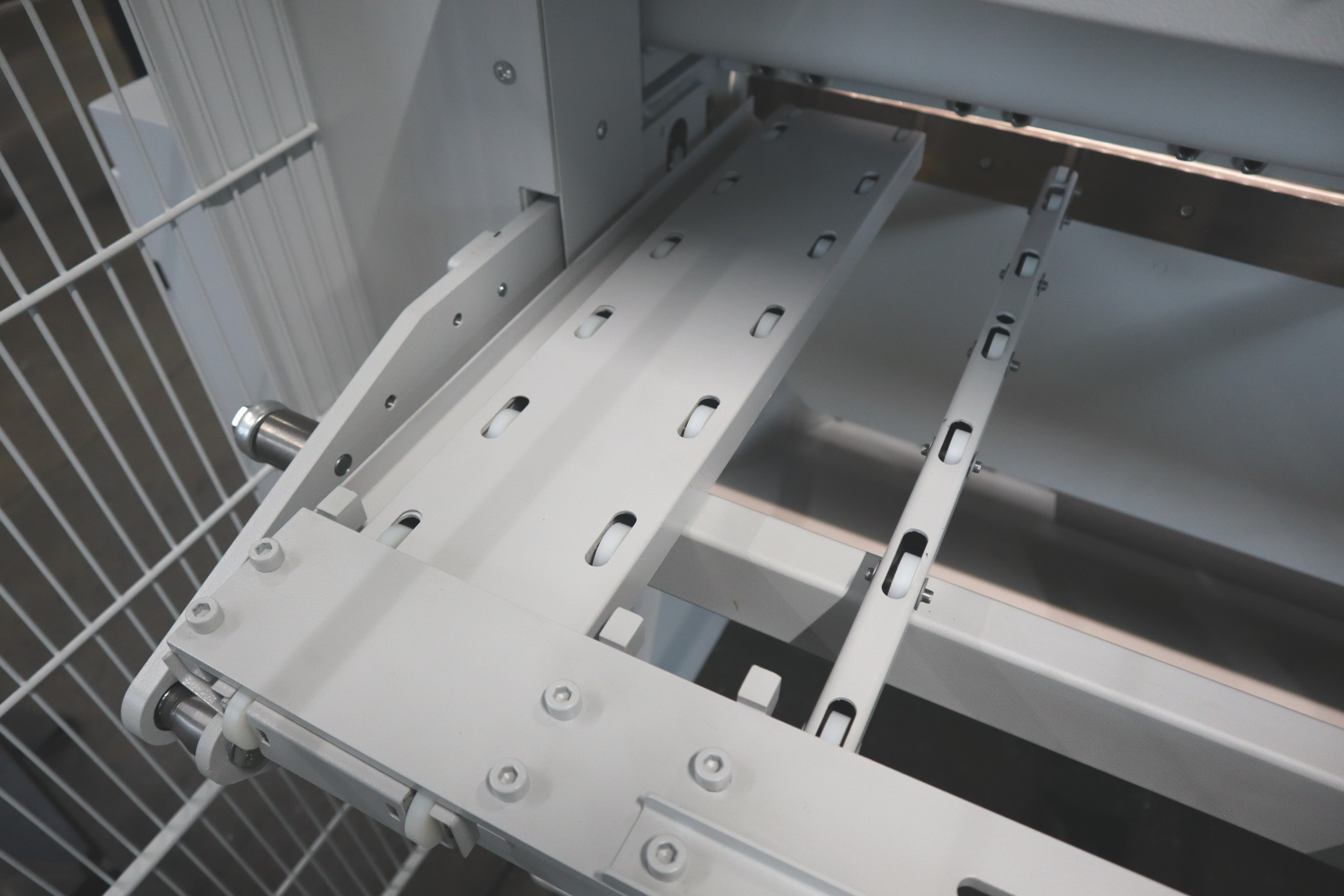

In the past, you had to decide how to deal with the clippings if you opted for the sheet holding device (BHV). With the new patented BHV from MHSU, Schröder from Wessobrunn-Forst offers a versatile electronically controlled mechanism: The device can guide sheet sections either forwards into the sheet chute or backwards onto a stacking carriage. For particularly sensitive surfaces, the BHV can also remain horizontal so that the clippings can be removed from the machine manually. This setting is also suitable for dividing tableware. The option of defining the forwarding of the cut material for each cut in the control system can be used as a scrap diverter: For example, the trimmed cut is routed to the sheet chute at the front, while the good parts are routed to the stacking carriage at the rear.

Further improvements

The geometry of the hold-down device has been modified to offer more operating freedom, and a small parts chute makes it easier to handle particularly narrow sections. Another new feature is the coil feed-through with safety package. The sheet holding device and backgauge are lowered to create space for feeding through sheets of any length.

The MHSU is still available in various versions, from 1000 to 3200 mm wide and for sheets from 1.5 to 4 mm thick. Various drive capacities are also available. In continuous operation, the MSHU achieves 34 strokes per minute.