Atlantem, a French manufacturer of windows, doors, facades, and closure devices and gates made of various materials, used the construction of its new plant in Saint-Sauveur-des-Landes to optimize the flow of materials within the company. For the storage technology, Atlantem chose Kasto to supply material to 15 upstream and downstream workstations and to unload finished products.

© Kasto

Atlantem, a subsidiary of the Hérige Group (formerly VM Matériaux) headquartered in Noyal-Pontivy in Brittany, employs 850 people at nine sites in France. In fiscal 2019, sales amounted to 140 million euros. The company manufactures aluminum, PVC, wood and hybrid windows. The portfolio also includes roller shutters, gates and entrance doors – currently the most comprehensive offer on the French market in this sector. Atlantem supplies its products exclusively to specialized companies throughout France through four distribution channels. Important customers are the construction industry, the building materials trade and plumbers. No products are exported.

Since its foundation in 1995, Atlantem has been growing steadily, also through the acquisition of several companies. To continue to be successful, the manufacturer faces clear challenges. Jérémy Jouvrot, Head of Continuous Improvement, explains: “Our customers demand quality products at competitive prices. Our strength is to offer all marketable products of window, door and facade construction as well as closure devices in all materials.”

Industry 4.0 requirements implemented

The move into the new headquarters in Noyal-Pontivy last year is an important milestone in the company’s history. The new administration building was designed in collaboration with the workforce and also serves as a showcase for the know-how of the entire Hérige Group. A year earlier, construction of a new plant in Saint-Sauveur-des-Landes in Brittany had already begun. 20 million was invested in an area of 18,000 square meters. There the company now manufactures multi-material windows and doors. Jérémy Jouvrot emphasizes: “We have created a factory with a high degree of networking. This 4.0 plant is intended as a showcase for our industry and will serve as a pilot project for the optimization of our other plants.” Atlantem also wanted to optimize its internal process flows with this new building. The company was therefore looking for an efficient solution for storage and to automatically supply the blank: “We wanted to have a central system for our entire profile storage and to automatically feed all our sawing machines. We also needed a dedicated station that would allow us to prepare orders by picking from several cassettes and also sort and store the profiles coming back from our painting facility,” explains Jouvrot.

© Kasto

References were clear

Atlantem did not make the search for a suitable partner for this project easy. In order to draw up specifications with all the important values and select a supplier for the new storage system, the experts visited around ten companies already equipped with various solutions available on the market. In the end, Kasto was chosen – and for good reasons: “The world-renowned company offers efficient and highly automated options for storing profiles,” explains Jouvrot. In addition, Kasto scored points by having its own subsidiary in France and a field service team located near the new plant that can always act quickly when needed. Kasto’s bearing and sawing technology experts finally recommended the Unicompact model.

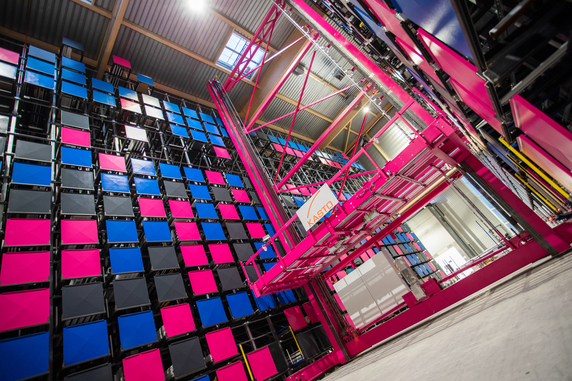

Kasto has designed this as a honeycomb storage system for a demand from about 400 places. It can accommodate loads of up to 8,000 kilograms per storage bin and can be used either as a self-supporting silo structure with roof and wall cladding or as a free-standing unit in existing buildings. The high storage density ensures efficient use of space. Fast cassette changes in fully automatic operation enable optimum supply times for the processing machines with only a small number of personnel. The Kasto Unicompact warehouse also carries out a permanent inventory. For the user, this means optimal inventory control. Different orders can be picked efficiently and economically. The storage system also has a modular design – changes or capacity adjustments can therefore be implemented quickly.

In Saint-Sauveur-des-Landes, the Kasto experts built a Unicompact warehouse 51.7 meters long, 22.2 meters wide and 16.1 meters high. A total of 1,504 storage spaces are now available there. The cassettes with a length of 6,600 millimeters, a width of 760 millimeters and a loading height of 770 millimeters each take a maximum load of one ton and allow profiles to be stored directly in the cassette or with customer racks. The energy-efficient storage and retrieval machine (SRM) reaches speeds of up to 160 meters per minute in longitudinal travel, while the lifting beam reaches speeds of up to 50 meters per minute. The stacker crane enables simultaneous handling of two cassettes: it picks up cassette A from a station and transports it to a preselected compartment. Once there, the stacker crane removes cassette B from the compartment. It then moves forward by one cassette width and places cassette A in the empty storage compartment. Then the stacker crane brings cassette B to the station.

Modern drive technology in combination with the Kasto system software ensures optimum driving behavior of the RBG. Jerk-free starting and braking processes prevent the profiles from slipping during cassette transport. The control of all positions in longitudinal and lifting travel is fast and energy-efficient. The system is controlled by the Kastologic warehouse management software. It independently manages article and inventory data as well as processing orders. Thanks to the modern, ergonomic and graphical user interface, system operation is very simple – just like the menu navigation: error displays and diagnostics output in plain text allow the user to immediately recognize the operating status. A transportable, ergonomic control panel with seven-inch touchscreen completes the system and allows the stacker crane to be moved in dead-man mode during maintenance work.

© Kasto

All expectations are met

The new warehouse solution has convinced those responsible at Atlantem. “Kasto has fully met our high expectations. The system, on which we prepare the orders from several cassettes, works smoothly and fully automatically,” says Jouvrot. “The control software is linked to our ERP system and was delivered with flawless customizations to match our way of working,” he adds. In addition, Atlantem has secured the stock management and simplified the handling operations for feeding the machining stations. “The new Kasto warehouse has also significantly reduced the workload for our employees,” says the continuous improvement manager.

Jérémy Jouvrot is also very satisfied with the cooperation with Kasto. “The Kasto team works professionally and knows its job perfectly. Almost all of our contacts speak French, which makes communication easier. Despite the country-specific cultural differences, we were able to complete this project on time and without going over budget,” summarizes Jouvrot, adding confidently, “We will use Kasto again for future solutions for our other sites. Kasto now understands our requirements, giving us a distinct advantage over our competitors. Because our ERP system now interfaces with Kasto software, this also simplifies the implementation of future projects.” Jouvrot thinks back to her last order: “The recent delivery of a UNITOWER also made it possible to improve the storage and management of leftovers.”

Web:

www.kasto.com