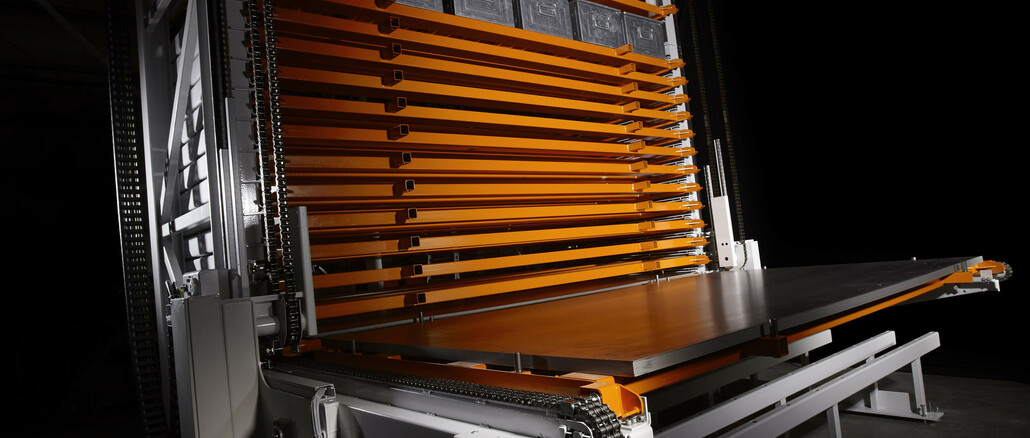

With the tower storage system Kastoecostore, the metal saw and storage technology specialist Kasto has a compact and standardized solution in its portfolio that is ideally suited for the storage of sheet metal, pallets and flat goods in various formats. The automated system scores with its low space requirement and high storage density, flexibility in material intake, short access times and an attractive price-performance ratio. For optimum performance, the Kastoecostore is equipped with the latest drive and control technology. This makes it particularly dynamic and precise and extremely easy to operate.

The Kastoecostore tower storage system is available in system heights of three to eight metres and is suitable for storing sheet metal, pallets and other flat materials with dimensions of up to 1,524 x 3,048 millimetres. Alternatively, it is available in the special format 1,524 x 4,000 millimetres. Flat pallets with a load capacity of up to three tons are used as load handling devices. Users can define up to three different heights between 50 and 950 millimeters per storage system. The Kastoecostore thus makes effective use of the available space. The tower bearing is particularly suitable for applications with a high variety of materials – for example in craft workshops, workshops, factory fitters’ shops or as buffer storage between production areas.

The load handling devices are automatically stored and retrieved and brought to the optimum loading and unloading height by means of a hoist. An additional lifting device such as a forklift truck is not required for cassette retrieval. This ensures short access times and an ergonomic way of working. The drive technology is equipped with modern frequency converters from Siemens, the drive motor is mounted stationary. This enables particularly dynamic and precise storage and retrieval operations. Robust roller chains ensure long-lasting and low-maintenance operation. The steel structure consists of standardized rolled sections and is dimensioned in accordance with the applicable earthquake guidelines. A comprehensive safety concept based on a safety control system prevents malfunctions and avoids costly downtimes.

In addition, the Kastoecostore is equipped with the AdvancedControl machine control system as standard. This is easy to use thanks to an intuitive user interface with touch screen. This allows fast and error-free work, even with frequently changing operating personnel. In addition, the bearing can also be installed close to the machine due to its compact dimensions.

The warehouse is covered by accessories such as movable station trolleys for rear loading and unloading as well as plug-in bolts for the pallets for individual storage space division. With the Kastoecostore, users get a space-saving solution for storing different goods with different dimensions.