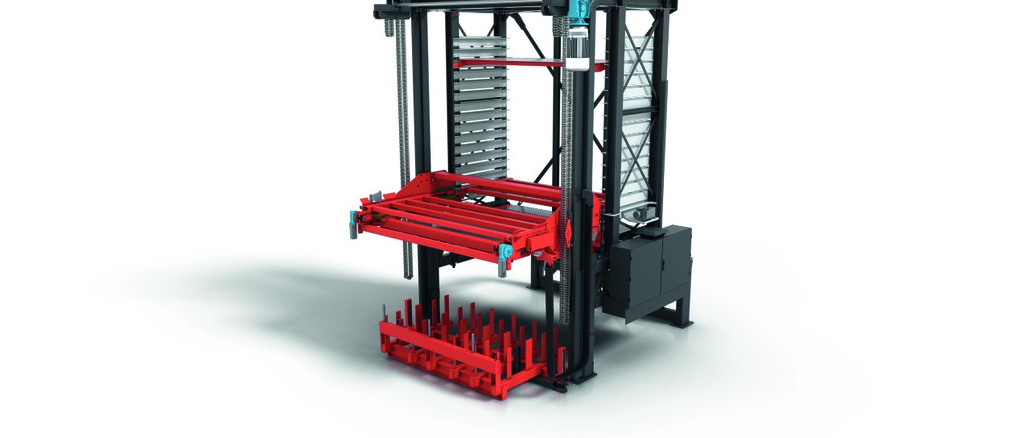

With the ByTower Compact automation solution, the productivity of a Bystronic laser cutting system can be significantly increased without taking up too much space. Due to its small footprint, the ByTower Compact enables low-manpower production for any size of company.

Not every sheet metal processing company has enough space available to set up new facilities or expand existing ones. Bystronic supports its customers in this situation with the new ByTower Compact: The new loading/unloading system with integrated storage enables unmanned or unmanned production with automated cassette changeover for any size of operation thanks to the low space requirement. It automates the work process of the laser cutting system and ensures that more parts can be cut per time unit.

Thanks to the sophisticated design of the ByTower Compact, sheet metal workers can thus increase the productivity of their Bystronic laser without taking up too much space. This is possible because the system is installed vertically directly above the shuttle table. The tower height is tailored to each requirement in order to make the best use of the available space.

The system allows two different configurations (with or without wooden pallet) to store packs of sheet metal directly on the machine, depending on the delivery. The material is thus immediately available.

The ByTower Compact is also suitable as a buffer store in which the material is prepared for low-man shifts at night and on weekends. Series orders can thus also be completed at off-peak times, the material handling is handled by the ByTower Compact. Materials for upcoming orders are conveniently prepared without interrupting the processes at the machine.

Further advantages of the ByTower Compact: It offers space for storing a wide variety of material types and thicknesses as well as for the return storage of the cut parts. Thanks to the compact, vertical design, the available floor space is used in the best possible way. It automates the work process and ensures low-manpower production. Reduced set-up times and an optimal material flow ensure high utilization of the laser cutting system – because sheet metal is stored where it is needed: at the machine.