Fagor Arrasate is taking another technological leap forward by incorporating laser cutters into its steel and aluminum processing lines. This technology complements the cooperative’s technical capabilities, opens up new business areas such as electric vehicles, and increases its sales by 15 million euros.

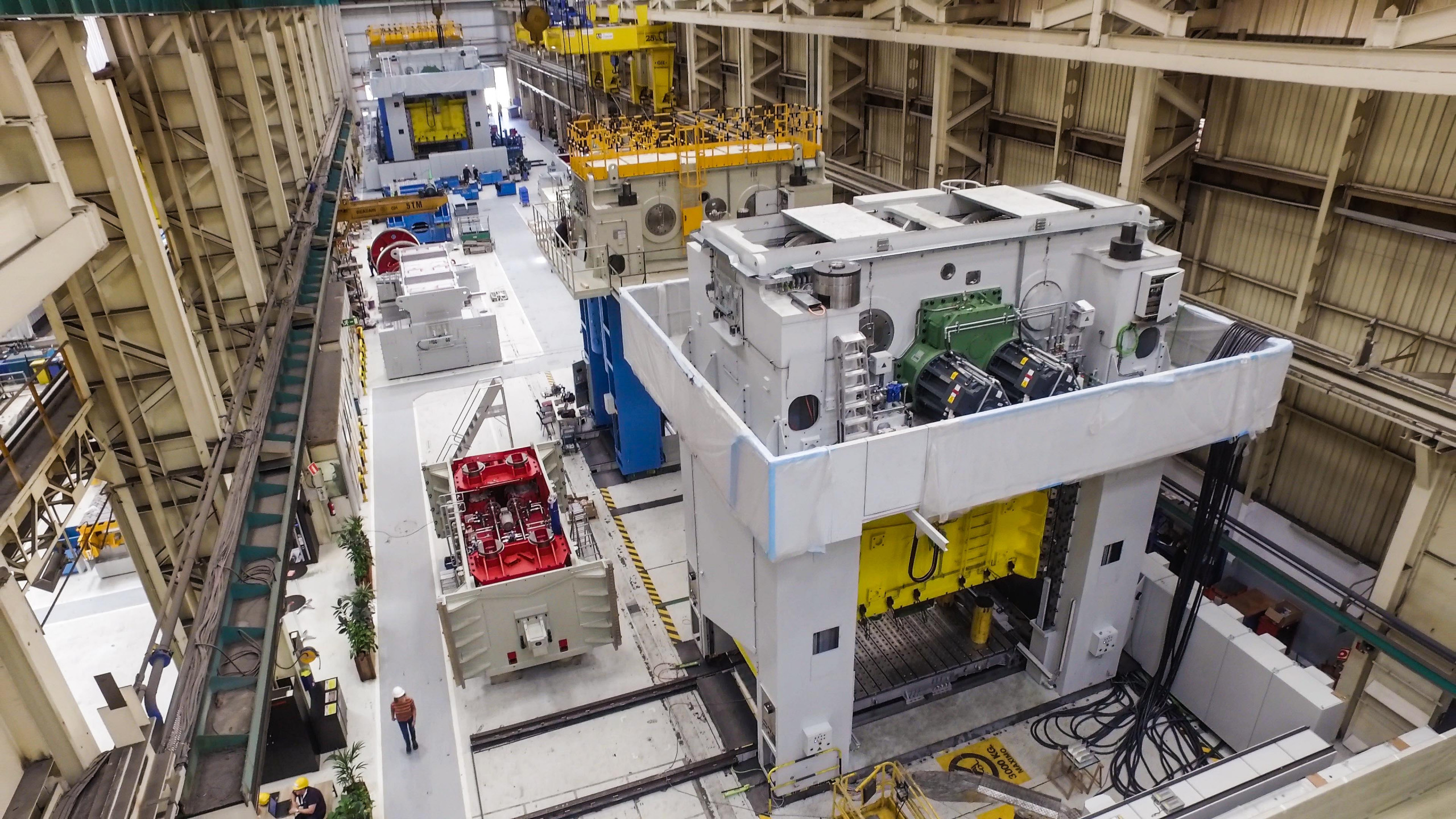

Fagor Arrasate, a specialist in the development of forming solutions for metals and composites, has recently added laser cutting technology to its portfolio for the processing of metal strip, which complements its technical capabilities and allows it to present itself on the market with an expanded offer.

The cooperative, based in the Basque town of Arrasate-Mondragón, recently integrated laser cutting technology directly from the coil at Danobat Group. The company sees its mastery of this technology and its experience as an incentive to tap into new market niches, such as manufacturers of new components for e-vehicles, but also other sectors such as air conditioning, steel tanks or household goods.

By bringing together the technology, know-how and expertise gained by Fagor Arrasate in the realization of the Danobat project, the company completes its current activities in the design and construction of cutting and sheet metal working equipment, giving a decisive boost to its technical capabilities in the development of laser cutting solutions and simulation software. As a result of the new laser cutting systems, the cooperative expects to generate additional annual sales of 10 to 15 million euros in 2024.

The project is part of the collaboration that Fagor Arrasate and Danobat Group – belonging to the Industrial Automation and Machine Tools Divisions of the Mondragon Cooperative – launched a few years ago to explore cooperation opportunities with the aim of strengthening their competitiveness in the market.

What exactly is laser cutting technology?

Due to their greater flexibility, laser cutting systems directly from coil offer an alternative to conventional cutting systems with press for certain market segments that do not require high production rates – such as in the niche markets newly created by electromobility:

Equipped with a laser cutting cell, these systems can be better adapted to changing production requirements. Any part can be manufactured at any time in a simple, flexible manner. Also, various materials such as steel, stainless steel and aluminum can be processed on these systems without changing tools, even if they are pre-painted and/or covered with a protective film.

Since no tools are required for blank cutting, production can be switched to new references within a very short time, eliminating the interruptions to production caused by tool changes. It also offers more flexibility in the production of complex geometric parts. In addition, the magazine for storing the tool sets as well as the initial investment and the ongoing costs for tool maintenance are eliminated.

Manufacturing directly from coil lowers production costs by optimizing material use and reducing waste.

Finally, installation costs are significantly lower because the system is compact and does not require pits, high buildings or cranes for mold changes.

About Fagor Arrasate

Fagor Arrasate is a world leader in the design and manufacture of customized solutions for the forming of steel, aluminum and stainless steel on presses, punching centers, slitting and coil processing lines, as well as in complete solutions for the production of complex metal components. The company also specializes in composite forming, hot and cold forging, and hot stamping.

Fagor Arrasate is a global player. Its major customers include the world’s most important manufacturers in the automotive sector such as the Volkswagen Group, General Motors, Ford, Stellantis and Tesla, strategic suppliers for this industry such as Gestamp and CIE, companies in the steel industry such as Tata, Arcelor Mittal, Acerinox, Gonvarri and Bamesa, and companies in the household appliances sector such as Bosch-Siemens, Whirlpool, Mabe, General Electric and Haier.

Thanks to more than 60 years of success, Fagor Arrasate has 6 manufacturing plants, 5 service hubs, an R+D+I center and numerous sales offices worldwide. Currently, Fagor Arrasate holds 660 jobs in its plants in the Basque Country, China, Mexico, Germany and the USA. In recent years, Fagor Arrasate’s average annual sales have exceeded 200 million euros; 85 percent of production has been exported.

The company is a founding member of Corporación Mondragon, one of the largest groups in Europe with a total of 80,000 employees.

Web:

fagorarrasate.com