Technical ceramics are highly interesting as a material for increasingly high-performance components. However, their hardness and low toughness make machining extremely difficult. MPK Special Tools has good news. The precision engineering specialists mill ceramics in the µm range and with exceptionally sharp edges. They have everything you need for customer-specific component production: innovative tools from Zecha’s Marlin 3D series, a wide range of manufacturing processes and decades of expertise in realizing even complex geometries with the tightest tolerances.

© MPK

The results at MPK Special Tools, experts in high-performance tools and components from Schwäbisch Gmünd, speak for themselves: various production steps such as milling, grinding or drilling can be carried out on the ceramic sample part made of partially stabilized zirconium oxide with the highest precision and surface roughness in the nanometre range. Depending on the objective, even with sharp workpiece edges and in a significantly shorter process time than would be possible with complex grinding.

“Only very few manufacturing companies achieve micrometer tolerances in ceramic milling. This allows us to take the milling of technical ceramics to a higher performance level compared to standard processes. For our customers, we can now realize delicate, complex component geometries, some of which would be impossible to produce using grinding, even more efficiently using milling,” sums up Christoph Steiner, MPK plant manager in Schwäbisch Gmünd.

Up to now, the state of the art for processing high-performance ceramics has mainly been grinding and polishing. These tried-and-tested methods can be used to produce high surface qualities precisely without putting too much strain on the material. The latter is crucial, because although such sintered ceramics are extremely hard and mechanically highly resilient, they are also brittle and only have a low fracture toughness. Machining techniques such as milling require a great deal of expertise and have so far been difficult to achieve such high precision in the µm range. Grinding processes enable greater precision, but take up a lot of production time.

MPK

Better ceramic processing thanks to tool innovation

The tools in the Marlin 3D laser series from Zecha Hartmetall Werkzeugfabrikation GmbH fundamentally revolutionize ceramic milling – with technology that sets new standards for precision and efficiency. The micro-tool specialists from Königsbach-Stein use lasers to manufacture their innovative torus and ball end mills as well as twist drills for ceramic and carbide machining.

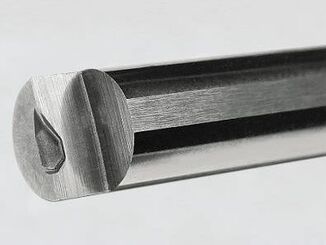

With this technology, extremely delicate, complex and previously unrealizable geometries can be precisely produced in extremely hard PCD and CVD cutting materials. In addition, it is possible to fit small tool diameters with many more cutting edges than before. An example of this is a torus milling cutter with a diameter of 6 mm and 42 teeth. The high number of cutting edges and the geometry adapted to the material result in a better distribution of cutting forces and therefore less heat generation. This is important because excessively high machining temperatures can affect the material properties of some ceramic materials.

Internal and shank cooling also minimizes friction and tool wear. Thanks to the new laser technology, Zecha is able to produce special tools with any shape, such as slot milling cutters. Furthermore, Zecha’s versatile range also offers the possibility of efficiently machining ceramic green bodies with diamond-coated tools.

This bundle of advantages comes up trumps at a crucial point in ceramic machining: with the highest surface quality, dimensional accuracy and process reliability that the market increasingly demands.

Ceramic components are of interest for more and more high-performance applications because technical ceramics can be manufactured from a variety of materials with a wide range of properties, some of which are unique, and can be tailored specifically to their intended use. The requirements in medical technology, for example, are extremely high, as biocompatible ceramic implants need a perfect fit in order to minimize health risks. In electronics, precision is required at micro level, as even minimal deviations in ceramic insulators, for example, can lead to malfunctions. And in the aerospace industry, where ceramic components are used in engines or heat protection systems, dimensional accuracy and surface quality are crucial for safety and efficiency.

Impressive manufacturing precision on the sample part

MPK Special Tools guarantees the required extreme accuracy, surface finish, process reliability and 100% reproducible quality: The CNC use of Marlin 3D tools in the iQ300 from Makino offers repeatable 3-axis machining precision down to the micrometer range, combined with advanced testing and measuring technology.

MPK’s trademark is the great versatility of its manufacturing processes, which have been perfected over the decades and range from milling technologies to surface, internal and external grinding when it comes to ceramics. This makes it possible to adapt the machining strategies to the specific and very different ceramic materials.

“In order to make MPK’s comprehensive expertise tangible for customers, we produced a sample part that reflects both the current requirements of the ceramics industry and the manufacturing diversity and expertise in Schwäbisch Gmünd,” explains Jannik Kimmel, Head of CNC Milling. The sample part was given a high-precision inner bore (diameter 1±0.001 mm). Using a PCD torus cutter with 42 cutting edges, dimensional accuracy of 0.002 mm, surface roughness in the nanometer range (Ra < 50 nm), flatness within 0.001 mm and radius tolerances of 0.005 mm were achieved during eccentric machining and on flat and bottom surfaces. Torx geometries, fluting, chamfers and standard threads could be produced with various tools with virtually no chipping. The size of the chipping is in the maximum grain size range of 5 µm. MPK’s expertise in ceramic grinding came to the fore on the back of the sample part.

Ceramic milling service: advice and fast production from batch size 1

“Our many years of experience in the carbide sector also helps us in some areas when it comes to the high-performance machining of ceramics. We find tailor-made solutions for individual requirements from batch size 1,” promises Jannik Kimmel. Customers who order larger quantities in particular benefit from the more efficient and faster production that ceramic milling makes possible compared to grinding. This can make an important contribution when it comes to time-to-market. It also saves customers from having to purchase the special, knowledge- and cost-intensive tools, machines and techniques required for ceramic processing. “And as convinced precision technicians, we also promise our ceramic clientele: With us, the µ takes the lead,” summarizes Christoph Steiner.

Background

MPK Special Tools GmbH, based in Schwäbisch Gmünd, has been an expert in precision technology for over 60 years. Experienced and competent, especially in stamping and forming technology as well as the manufacture of special tools according to customer drawings, the company offers solutions with the highest precision and any number of pieces for active parts made of carbide and steel along the entire process chain.

MPK’s trademark is well-founded know-how in a wide range of manufacturing processes such as CNC grinding technology, start hole shooting, wire and die-sinking EDM, carbide milling as well as finishing and shrinking technology, realized with a selected park of state-of-the-art production machines. The latest service is the micrometer-precise CNC milling of ultra-hard ceramic materials.

MPK Special Tools GmbH is a sister company of ZechaA Hartmetall Werkzeugfabrikation GmbH from Königsbach-Stein.