Ecological and sustainable aspects are also playing an increasingly important role in industry. There are enormous differences here, for example, in the machinery. When it comes to the appropriate solution for cutting, waterjet cutting is considered one of the most environmentally friendly cutting technologies on the market: no toxic fumes are produced, no gas is added, and air extraction and filtration are not required.

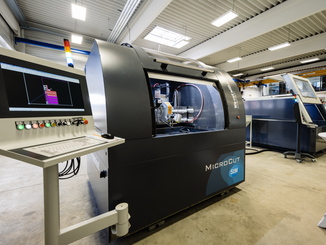

Environmental protection begins with the construction of the machine. MicroStep traditionally manufactures all machines according to strict guidelines that apply nationally at the production sites in Slovakia and are also subject to European environmental directives. In addition to environmentally friendly production, environmentally friendly design is also an important part of the MicroStep principles.

MicroStep waterjet cutting machines have encapsulated drive systems that safely prevent lubricant leakage. The motors used are optimized for maximum efficiency, and in the case of the cutting heads, attention is paid to the possibility of replacing wear parts such as nozzles and mixing chamber separately and continuing to use the cutting head. If desired, it is even possible to use zinc-free support plates for the workpiece support.

© MicroStep

Careful handling of oil and water

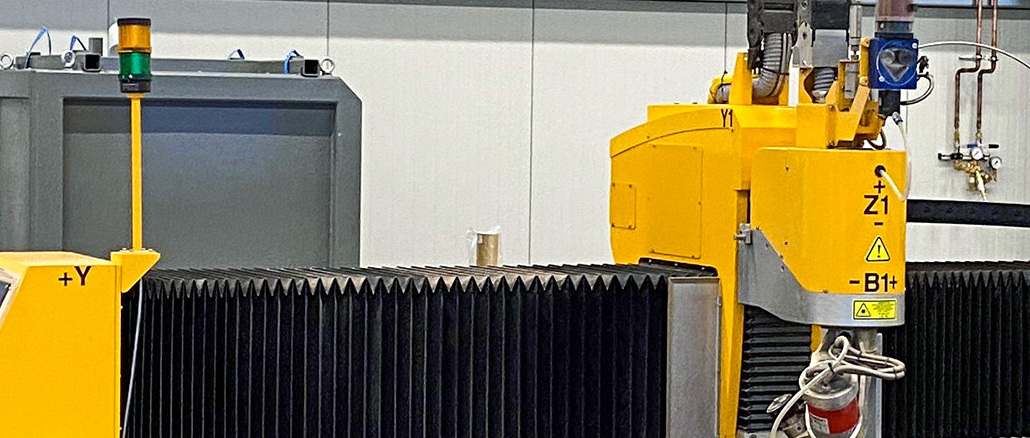

The ultra-high pressure pumps used by MicroStep are also environmentally friendly. In the case of direct-drive pumps, the cooling water is no longer completely or at least partially conveyed to the drain, as was the case in the past; in state-of-the-art solutions, it is first used for cooling, then fed into a closed tank, and finally used completely for cutting. This can significantly reduce water consumption.

Manufacturers have also made great strides in recent years in the areas of oil consumption and oil-related environmental safety. For example, modern intensifier pumps operate with the smallest quantities of hydraulic oil and fast, efficient drive motors. Leakage holes, which used to be used for visual inspection, are now scanned with sensors and the escaping medium is collected in closed containers. In the event of a leak, the entire oil content of the pumps used in MicroStep is absorbed by integrated sumps and can therefore not be released into the environment. Even in water protection areas, this means that an additional sump is no longer required. A major advantage compared to outdated waterjet cutting systems.

Preparation, additives and waste disposal

When it comes to the environmental compatibility of waterjet cutting technology, it is not only the CNC machine that needs to be considered; another important aspect is the consumables: the water must meet certain criteria in terms of its composition. In addition to the pH value and the degree of hardness, other different criteria are queried. If the water does not sufficiently meet these requirements, it must be treated. There are various ways to do this, using filters or additives to meet the manufacturer’s specifications.

During a MicroStep technology consultation, the experts objectively look at the production processes and the products to be manufactured, identify potential for optimization, develop suggestions for improvement, and plan the path to modern manufacturing in detail with the customer. In the course of this independent and tailored advice, the water quality is also checked and, if necessary, treatment to meet the customer’s needs is taken into account and offered. The additive recommended by MicroStep is environmentally friendly and does not contain any substances subject to designation. It is safe for discharge into wastewater and is not subject to GHS labeling requirements.

© MicroStep

Natural products for optimal results

The abrasive sand, like the water, is a natural product. The sand is offered on the market in different qualities and grain sizes. MicroStep works together with its partner GMA Garnet. The experienced and world-leading supplier of industrial garnet sand supplies high-quality products and also takes care of the recycling of the associated cutting waste. Sand as well as water are pure natural products and in the form used absolutely uncritical for the environment.

When it comes to the environmental compatibility of the waterjet cutting process, however, there is a third component to consider: the “notch material”. In other words, the portion that is ground out of the sheet, i.e. the flat material to be cut, during cutting. The volume of the notch material can be roughly calculated by multiplying the cutting width by the cutting length and the material thickness. The percentage of notch material in the total waste varies with speed, material type and thickness, and amount of sand used. For example, the percentage of notch material ranges from 0.3 percent by volume when cutting 5 mm thick aluminum to 6 percent by volume when cutting 50 mm thick steel.

This notch material, which the operator of a waterjet cutting machine must dispose of as waste along with his used abrasive sand, should ideally be recycled. MicroStep partner GMA Garnet also supports customers in this area. To keep freight costs low and avoid empty runs, GMA Garnet not only delivers the required abrasive sand, but also takes back the previously produced slurry in the course of this delivery. The sludge is later analyzed and checked for any contaminants. Provided you cut the usual materials such as stone, aluminum, steel et cetera, the sludge is usually recyclable. The analysis is valid for five years. If the sludge is contaminated – for example by heavy metals – then the waste is taken to an appropriate landfill according to its respective classification. The analyses required for this are repeated annually.

Systematically protect the environment

During recycling, the notched material is separated from the sand and returned to the metal cycle. The sand is largely recycled and returns to the market in the form of abrasive sand of smaller grain sizes. The components that can no longer be recycled go into road construction as fill material or are used in other sensible and environmentally friendly ways.

Web:

www.microstep.com