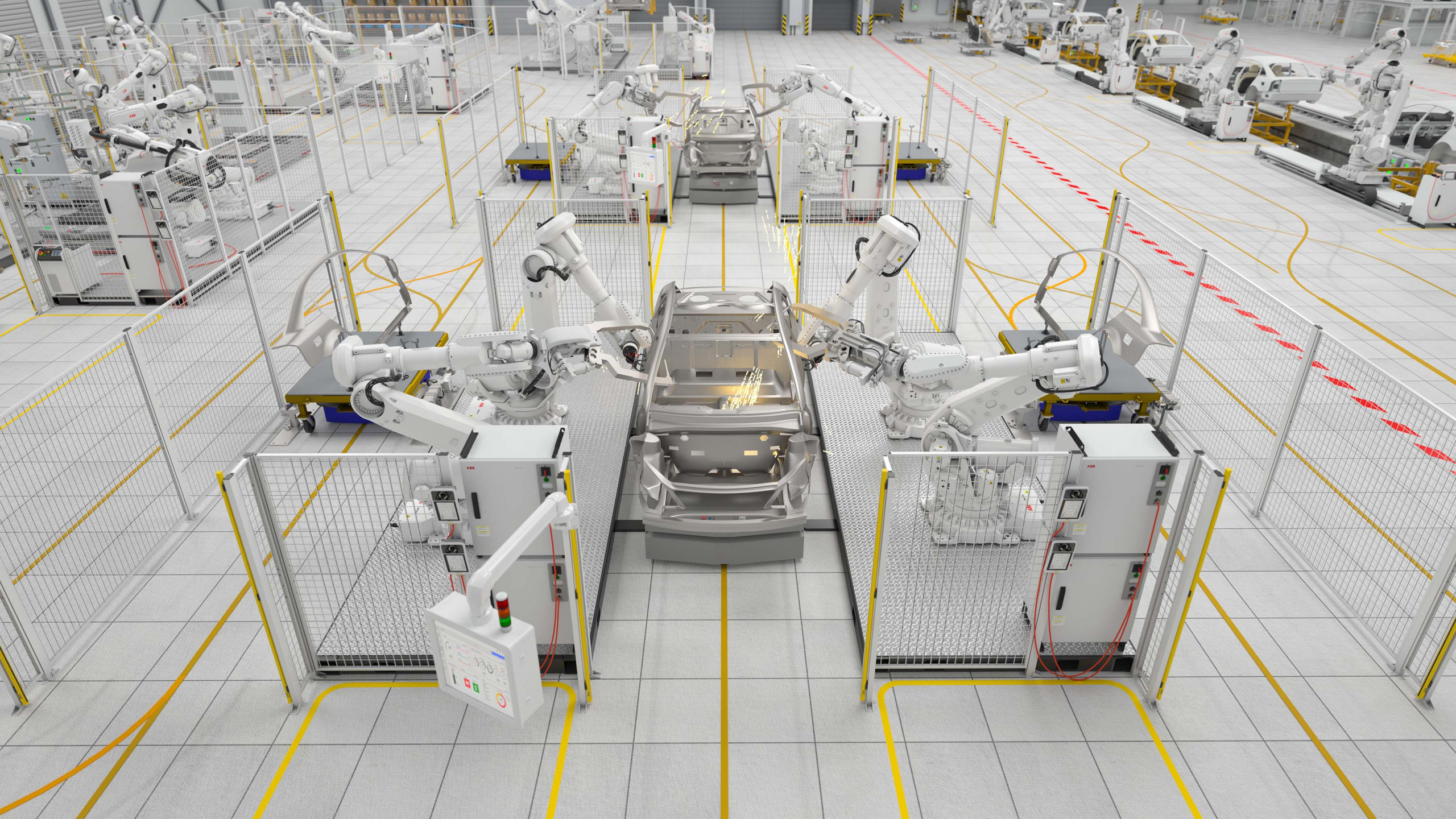

ABB expands its portfolio of large robots with four new models in 22 variants. Customers benefit from greater choice and coverage, as well as higher performance and energy efficiency. The next-generation models, designated IRB 6710, IRB 6720, IRB 6730 and IRB 6740, cover payloads from 150 to 310 kilograms and are available in reaches from 2.5 to 3.2 meters.

© ABB

“Sustainable production is a high priority for vehicle manufacturers. Some 78 percent of companies consider it important for their business, and for another 77 percent it is a priority for their customers1,” emphasizes Marc Segura, head of ABB’s Robotics Division. “The four new ABB robots are available in 22 variants and enable energy savings of up to 20 percent. This is in response to our customers’ demands for greater choice and flexibility for more sustainable production. The new robots will help our customers build resilience in a variety of industries, including automotive, general manufacturing, foundry, food and beverage and logistics.”

The improved energy efficiency is achieved through OmniCore control and a lighter robot design. In addition, OmniCore provides precise motion control. Thanks to TrueMove and QuickMove technology, the robots achieve good 0.03 mm repeatability. This makes the new robot series suitable for complex tasks such as spot welding, laser welding, screwing and riveting, ensuring high assembly quality in vehicle manufacturing.

“Our new robot series goes hand in hand with the requirements of a rapidly growing electric vehicle industry. As manufacturers expand production of e-vehicles and batteries, they can choose the right variant from a wide range of ABB robots, for example, to assemble batteries of different sizes from individual cells and modules to entire packages. The robots can also perform tasks such as high-precision assembly of body parts or spot welding tasks. They are also able to reach confined areas in the vehicle to install seats or dashboards, for example,” says Jörg Reger, head of ABB’s Automotive business line.

Web:

www.abb.de/robotics