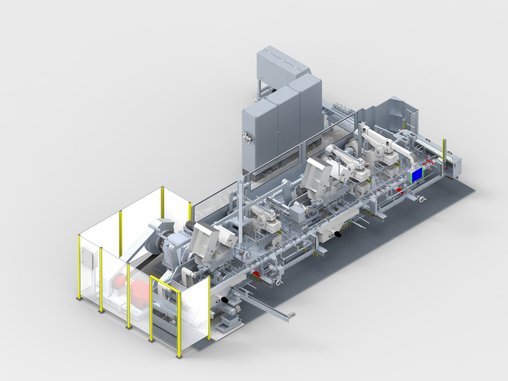

At Wire 2022, Amba will debut its new all-in-one machine for the production of fully threaded screws 420 mm long with 10 mm outer diameter directly from coil. With a throughput of up to 80 pieces per minute, it sets a new benchmark.

© Amba

The new line operates according to the all-in-one principle developed by Amba: all process steps from uncoiling, straightening and cutting the wire to length, to forming the head and rolling the thread are carried out in the same machine. It achieves a cycle rate of more than 80 pieces per minute.

420 mm long fully threaded screws are used in structural timber engineering in increasingly large quantities. The background to this is the current trend for more and more buildings to be constructed in wood. In the south of Germany, this has long been common practice, and more and more buildings are being built of wood in the north as well. The new machine enables screw manufacturers to produce both fully and partially threaded screws at high cycle rates directly from the wire, meeting the growing demands of the market.

Georg Haas, Amba’s sales manager, explains why the company developed the new machine: “In our all-in-one machines, the throughput is significantly higher than in systems that specialize in individual processing steps – rolling, for example: The parts no longer have to be fed, clamped, machined and removed individually. In this way, discontinuous production is transformed into quasi-continuous production. In some applications, this brings an order of magnitude increase in productivity.”

The first machine for the production of 420 mm long fully threaded screws will soon be delivered to a customer in Germany, and further orders have already been placed.

Facts & Figures

Aachener Maschinenbau GmbH – usually called “AMBA” – was founded in 1908 in the environment of the Aachen needle industry, which was renowned worldwide at the time. Since then, the company has become an internationally recognized specialist in machines for cold forming metal components. Today, Amba mainly manufactures special machines for the production of long components whose cross-section changes along their length – for example, screws with a length between 60 and 2,500 mm, as well as tubes and spokes. With the all-in-one principle, Amba claims to be the only machine manufacturer in the world to realize the continuous production of long or complex parts in a single machine: From the semi-finished product – be it wire or tube – to the finished, packaged product, all process steps take place in one machine. At the company’s current headquarters in Alsdorf near Aachen, 80 employees work in development, design, production and customer service.

Web:

www.amba.de