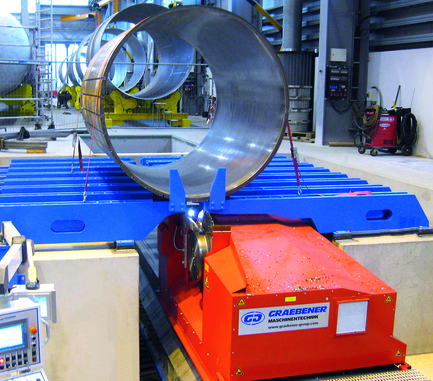

Graebener developed its first milling systems for the preparation of weld seams on pressure vessels back in the 1980s, initially only for use in what was then its own large-diameter pipe mill. In cooperation with Ingersoll Werkzeuge GmbH, the machines became products for the world market, which are now in great demand especially for the construction of offshore wind towers and their foundation structures.

© Ingersoll

Gräbener Maschinentechnik (GMT) looks back on a company history of more than 100 years. In 1921, the Graebener family company started pipe and apparatus construction. Until 1955, the focus was on the production of heavy iron and sheet metal structures, including steel and boiler construction. Subsequently, a large-diameter pipe mill was built and established in Netphen-Werthenbach in the Siegerland region, which was then sold to Indonesia at the end of the 1990s.

Since then, Gräbener Maschinentechnik GmbH & Co. KG has concentrated entirely on mechanical and plant engineering. The company, which currently employs around 80 people, focuses on the development and design of hydraulics, mechanics and automation as well as on the assembly and commissioning of new plants and retrofits. The necessary machine components, such as steel structures, but also all other parts, are purchased from suppliers mainly in the regional area. Graebener therefore sees itself as a “virtual factory”, since it does not operate its own facilities for component production.

The past is nevertheless present at the company’s headquarters. On the one hand, production still takes place in the historic halls. On the other hand, the experience built up here over decades and the constant improvements made form the basis for the company’s current business success.

Joint development from the beginning

The construction of our own circular and longitudinal seam milling machines was started in the mid-1980s out of a heavyweight problem. The pipes produced in Werthenbach became increasingly thick-walled and caused transport problems. The pipes, which were up to 70 meters long and weighed up to 70 tons, therefore had to be finally welded together on the construction sites. The idea of a mobile milling machine was born, with the help of which the weld seam preparation on the pipes could be carried out on site.

For the milling machines, Graebener worked with Ingersoll from day one. Milling heads for circular and longitudinal seam milling were jointly developed for machining the tubes, but also for other fields of application, such as weld seam preparation on sheet metal and profiles. At the beginning, they still had to contend with considerable difficulties, as Dieter Kapp, managing partner of Graebener, reports: “The first milling heads only lasted a few days and our gearboxes were damaged just as quickly, as there was still no experience whatsoever for this new machining method.”

But Graebener and Ingersoll stuck to the concept and pursued continuous development of the machines and milling tools over the years. A few years after the first milling machines for internal use, the machines were durable, powerful, process reliable and thus marketable. McDermott in Scotland and Sif from the Netherlands, at that time two market leaders for thick-walled pipes, vessels and apparatus, were the first two customers for Graebener. Sif is today one of the leading manufacturers of foundation structures for offshore wind turbines.

© Ingersoll

Market leader in weld seam preparation

The machines manufactured by Graebener for weld seam preparation were the first of their kind. With more than 200 milling machines delivered within the past 25 years, Graebener is considered the market leader worldwide. Of these machines, around 150 are used for milling weld preparations for circumferential and longitudinal welds on cylindrical and conical components with diameters of up to 15 meters and wall thicknesses of up to 200 millimeters. In the past few years alone, over two dozen circumferential seam cutters and half as many longitudinal seam cutters have been sold to the wind offshore industry.

In the meantime, all well-known manufacturers of foundation structures for wind turbines in the onshore and offshore sector use milling machines from Graebener. The offshore market in particular is experiencing a sustained boom and providing Graebener with high demand. Wind power is to be used for green energy in more and more parts of the world. The machine manufacturer has already responded to a new market developing in the USA with its own subsidiary in Texas, where a transportable circular seam milling machine is available as a demonstration unit. New wind farms are also being built off Japan’s coast. In this case, a manufacturer of monopiles wants to carry out the complete assembly process outdoors rather than in a hall. To be able to meet this requirement, Graebener develops machines that are also suitable for outdoor use in the open air.

The monopiles for wind towers are always assembled from several individual cylindrical and conical steel rings, the so-called pipe sections. Typical dimensions for such a shot are a diameter of 13 meters and maximum lengths of 4 meters. With wall thicknesses of 120 millimeters, this results in an individual weight of up to 150 tons per shot. After bending, the wefts are first welded longitudinally from the inside and then from the outside. This is followed by the assembly of up to six shots into a section. Three to four of these composite sections, in turn, form the so-called monopile. A monopile has a total of about 192 meters of longitudinal and 940 meters of circumferential seams and a total weight of up to 2,500 tons.

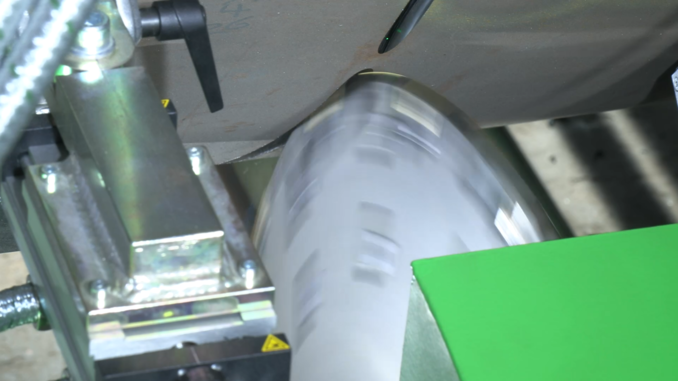

Graebener’s milling machines enable very efficient, economical preparation of the outer weld seams. The process is fast, material-saving and precise. While the carving out of the internal weld root was previously created manually with a so-called gouge by spark erosion and subsequent grinding process, a disc cutter from Ingersoll now creates a narrow cup-shaped groove. The angle of this external weld preparation, which was conventionally about 60°, is reduced to 16° by the milling process using disc cutters as standard. This reduces the subsequent material insertion and welding time. The total cost savings for weld seam preparation with Graeben machines compared to conventional machining is 38 percent. In several passes, the cutter penetrates up to 150 millimeters deep to the root layer of the internal seam. The clean, uniform groove, which requires no further finishing, is the prerequisite for an automated submerged arc welding process (under powder). The milling process is also ten times faster than conventional gouging. The process is equally well suited for repair work on the welds to mill out local defects.

For circular and longitudinal seam milling, Ingersoll supplies V-shaped side milling cutters with radius R7/R8 in the head area and opening angles of 14° to 16°. In addition, customized side milling cutters are also offered. The diameters of these large tools are mainly between 850 and 1060 millimeters. The side milling cutters are equipped with different cutting inserts for the head and flanks of the tool. As a rule, these are inserts with negative cutting geometry. A body guard or cassette inserts are usually used for the head cutting edges because of the increased tooth load. This can be dispensed with for the flank cutting edges, since the flank angle results in a lower tooth load.

© Ingersoll

Vibrations are a challenge

Depending on the component, vibrations occur on the tube body during machining. This is a big problem, because they can cause chipping on the cutting edges and subsequently cause wear. When designing the machine, Graebener therefore takes care to match the milling head and gearbox to the expected vibration behavior. The bigger problem, however, is the huge workpieces. Here, Graebener puts all its experience to work in order to offer the optimum solution for the customer’s particular machining situation.

On the one hand, the pipe turning device has a major influence on the vibration behavior of the components, but on the other hand, the diameter and wall thickness of the pipes also play a significant role. Thin-walled shots in particular tend to vibrate during machining. To prevent cutting edge chipping, Ingersoll uses inserts with a particularly tough base substrate, which is given the necessary wear resistance by a corresponding coating.

In addition, the pipe sections have a certain ovality. In order to compensate for this during circumferential seam milling and still achieve a consistent milling depth, the milling depth is automatically corrected with the help of sensors. Lateral drift of the workpiece on the rough turning device is compensated for on the circular seam milling machines by means of a sideways milling cutter adjustment.

© Ingersoll

Individually manufactured plants

The machines built by Graebener are standardized and can be specifically adapted according to customer requirements. The main aim here is to bring the machine into the ideal working position depending on the production environment. Christian Landau, Sales Manager at Graebener, outlines the possibilities: “For example, our machines can be moved on rails or brought to the appropriate milling height with different substructures. A typical example is monopiles with different pipe diameters and cone transitions.”

A selection of basic machines in the power ranges between 30 and 65 kilowatts, which are suitable for various milling depths, serves as the basis for these individual solutions. “We have designed the performance of our machines so that we can run at optimum cutting speeds for the respective application,” explains Dieter Kapp. “We place a lot of emphasis on the optimum torque at the milling spindle.”

Meanwhile, there are new development goals for Graebener and Ingersoll: Machines and tools optimized for machining demanding materials. They are not used for monopiles, but are used in other industries in which Graebener is active. In pressure vessel, tank and special pipe construction, Graeben’s milling systems also machine materials such as stainless steels, high-strength aluminum alloys and special steel grades.

One problem here is the range of different material compositions with different properties. “There is no standardized solution for the many materials,” says Andreas Bulla, tangential tooling/thread milling product manager at Ingersoll, who explains the strategy. “In order to generate as little heat as possible at the cutting edge, depending on the material, we optimize the cutting geometry, for example. Additional heat grooves in the rake face area minimize the material-related sticking of chips to the cutting edge and reduce frictional heat by minimizing contact surfaces.”

Depending on the material, Ingersoll uses different geometries and qualities for the inserts here. In contrast to the machining of steel tubes, positive cutting geometries are preferably selected for the machining of stainless steel for both the head cutting edges and the flank cutting edges.

Dipl.-Phys. Manfred Flohr, freelance technical journalist

Web:

www.graebener.com