Deeg GmbH is a medium-sized contract manufacturer for sheet metal processing. What began almost 30 years ago with a mortgage on the company’s own house to finance the first Trumpf laser cutting machine is now entering the next round with the online ordering platform LaserCloud. The sheet metal fabricator came across the digitalization experts at Optimate via Trumpf. In a joint pilot project, an automated feasibility check was integrated into the web store.

“We started with laser processing and then gradually added subsequent processes such as bending, welding and the assembly of complete modules,” says Joachim Deeg, explaining the company’s development into a full-service provider for sheet metal components. The Managing Director of LaserCloud GmbH still works in the family business at the same time, before the online ordering service was spun off as an independent limited company a year ago.

With 185 employees, Deeg uses laser cutting and bending machines to manufacture a wide variety of sheet metal components in large series. The 17,000 m² production area is equipped with modern machinery, mainly Trumpf machines. “There were times when we had to hire up to ten new employees every year, and we expanded the production area every two to three years,” recalls Joachim Deeg.

The clients are predominantly large industrial customers from the region who order medium to large series of 100 to 1,000 pieces made of structural steel, aluminum or stainless steel. “However, we have also seen product groups with several thousand parts over the year, or certain welded constructions with many hours of processing on one component,” he specifies.

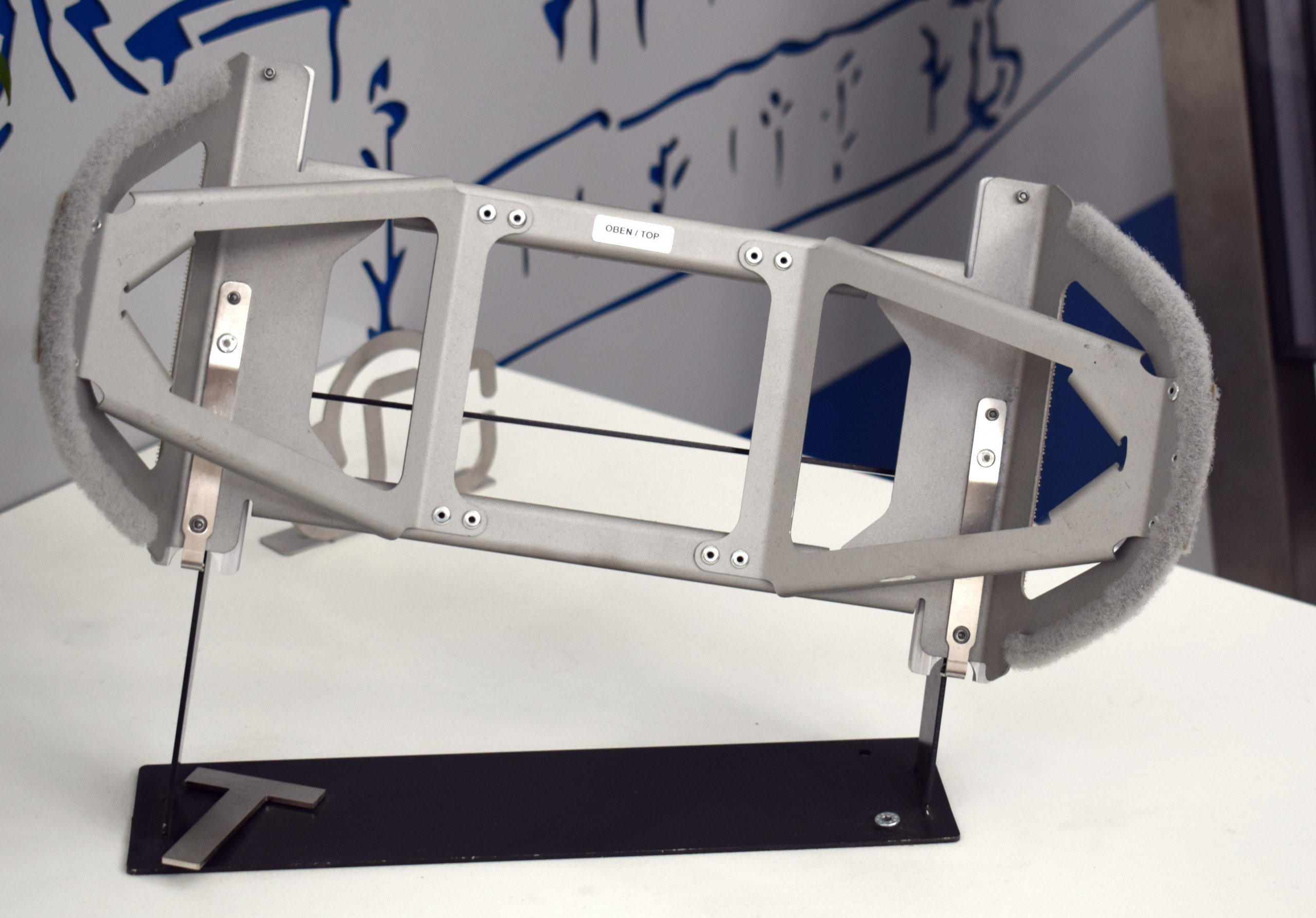

© Optimate

When batch size 1 disrupts the series

Time and again, customers also came with smaller batch sizes or even quantities of 1, for example to have a prototype for product tests produced promptly. However, the laser machines are already scheduled 7 to 8 days in advance for the series orders. All production orders are planned and loaded via the ERP (APplus) and PPS (Oseon), “married” with the NC order data in the production-related work preparation and then sent directly to the machines.

NC programming at Deeg uses TruTops Boost almost exclusively, and in a few exceptions also SolidWorks with Sheetmetal adapter. With production running at full speed, the individual and rush orders had to be processed somehow without interrupting the series – with full order books and often in three-shift operation, this was usually a real challenge. The effort involved was correspondingly high. “Our delivery times are between 6 and 8 weeks, and when we had to keep pushing smaller series or prototypes in between, it was always a real balancing act to keep to the times,” says Joachim Deeg, explaining the situation before LaserCloud was spun off. This meant that some urgent requests could not even be accepted – certainly not an easy decision for regular customers.

Process individual orders separately

“We wanted to remedy this and needed a solution,” recalls the Managing Director. This led to the idea of setting up a separate department for this purpose. A new hall was built and the company acquired its own machinery in order to be able to manufacture individual orders separately from series production. These orders should also not be processed via the normal order entry system, but completely separately, preferably via an online platform.

The new ordering philosophy at Deeg is now as follows: if you only need a simple bent part, you can go to the web store and have it delivered within a few days. If you want to order series, you can do so as usual via order processing. The new department soon became a company in its own right: LaserCloud GmbH.

A TruLaser 3030 fiber laser cutting machine, a TruBend 5170 press brake, an Arku sheet metal deburring machine and a fladder deburring machine are available for the fast weaving jobs. “With our own machinery, we at LaserCloud are also quite flexible. If a customer needs their sheet metal part the very next day, we can manage that,” assures Joachim Deeg. To ensure that such an individual order really does go through quickly, the 15 employees at LaserCloud have to be proficient in all processing methods in order to completely manufacture and then assemble a sheet metal component.

The parent company has separate departments for laser cutting, deburring, welding and edging. “We need universal employees who can do everything. That’s the only way we’ll be able to deliver within a few hours,” says the LaserCloud Managing Director.

© Optimate

Webshop for individual rush orders

“At this point, I was wondering why there wasn’t actually any software for a job shopper in the sheet metal processing industry to create a web store and process small series and individual parts online.” Software developers known to the junior boss said it was a project worth millions. However, Joachim Deeg did not let up, as customers had also repeatedly indicated that they would like to place the smallest orders with their long-standing sheet metal partner, without being able to accept long delivery times.

In the Trumpf environment, Deeg then became aware of RockIT Manufacturing as a potential webshop supplier. The IT specialists from Ditzingen, all former Trumpf employees, create online stores for industry, especially for sheet metal workers.

Once the web store for LaserCloud had been designed, online orders could be placed, but the design department still had to check the feasibility of each component. “What use is a digital ordering process if we still have to intervene manually every time?” says Joachim Deeg. “Then the web store becomes a one-way street.” His wish was to integrate a running calculation for the many individual orders and a feasibility check into the web store so that everything runs as automatically as possible.

Specifications for the feasibility analysis

RockIT then also integrated the calculation into the LaserCloud store and referred to the start-up Optimate in terms of feasibility analysis. The calculation was quickly integrated, RockIT adapted the interface, and later also the connection to the Optimate solution.

“We had offers of up to two years for the integration of feasibility into our web store,” recalls Joachim Deeg. “But what manufacturing company can afford to wait two years until the feasibility of the sheet metal components is realized in the order store? Optimate doesn’t think in years, but in short sprints.” The start-up’s software development team then implemented the first operational programs within two weeks.

LaserCloud’s expectations of a feasibility study were set out in a specification sheet. It was important to Joachim Deeg that there was a design and a production test. “Our aim was that once the feasibility had been checked, i.e. the component was ready, the stored step file could be loaded directly into our CAD program with one click to create the NC program. We then went through all of this and also determined what we had to contribute from our side.”

Two LaserCloud employees were entrusted with the technical clarification. Together with the Deeg specialists from programming, design and work preparation (AV), topics such as laser processing, cutting and much more were discussed. The expertise of the in-house bending department was also indispensable in determining where there was a need to adapt designed customer components and what type of feasibility test could be considered for bending.

“As part of a project team here at LaserCloud, we kept looking for the interface to Deeg, then spoke to RockIT and Optimate and wrote it down in the specifications. It was a challenge for us to translate all our technical expertise into this software thinking.”

Feasibility means design and production testing

If a webshop user uploads their component to the platform as a design drawing in Step or DFX format, the first step is a feasibility check. This involves analyzing whether the component is structurally feasible, including in terms of bending radius, contours and leg lengths. The customer then enters their material and other parameters for the production test. The machine and tool data of the sheet metal worker were stored for this purpose. Based on these characteristics, the digital feasibility analysis checks whether the ordered component can be manufactured with the machines at LaserCloud.

In the beginning, it was still uncertain how secure it all was and whether the orders would actually go through. After all, nobody wanted half of the components to be rejected by the feasibility check. It was therefore necessary to find a middle way. On the one hand, not too many online orders were to be rejected; on the other hand, the aim was to ensure that parts that pass the feasibility check can actually be manufactured with a high level of process reliability.

“The fact that Optimate not only has software experience but also in-depth sheet metal knowledge was of course very helpful to us,” emphasizes the LaserCloud Managing Director. For example, with regard to the 3D feasibility of bent parts: How are components bent, with what radius and with what minimum leg length? “We were always able to get straight down to business without having to explain much.”

If Optimate’s feasibility check rejects a component, it can be placed in a second shopping cart with non-calculable components. An order is then not triggered; the design data and parameters entered are sent to the design department for manual checking.

Typical errors that the design check does not allow through are open contours, duplicate contours, several components in one file, incorrect line colors, different sheet thicknesses in one component or a drawing header with legend contained in the file.

During production testing, a typical reason for rejection is the wrong part size for the large-format laser cutting machine or the incorrect sheet thickness. Parts that are longer than three meters fall through when bending – the machine can’t handle more.

© Optimate

Double benefit from the extended workbench

The new laser and bending machine for LaserCloud was delivered in August last year. Just at this time, a major Deeg customer had an additional and high demand for sheet metal. The very first order for the webshop was a large series, which was not even ordered online.

The online store went live in October. Since then, orders have been arriving daily, 95 percent of which are new customers and none of which are existing customers of the parent company. 100 customers are registered, and the trend is rising. The customer alone, for whom the LaserCloud online ordering platform acted as an extended workbench, now orders 400 items a week via the web store, all individual parts in batch sizes 1 to 5.

In the medium term, contract manufacturer Deeg will certainly also benefit from the new subsidiary. If you order individual sheet metal parts from LaserCloud today, you could become a high-volume customer tomorrow. Joachim Deeg explains: “If a new customer needs a prototype of one or two components, for example, they can order them through us, receive their delivery within a few days and can test them. If the tests are positive and they want to go into series production, our parent company is there in the background.”

From the web store to the machine

At the moment, the programs are still imported manually into CAD, and an in-house designer looks over them again. However, it is planned that in future the CAD programs will be automatically filled with the uploaded step files after the feasibility check. “We want to get a feel for what kind of orders and components are actually coming in via the web store, which is why we are already looking at this again in the design phase,” says Joachim Deeg, explaining his approach.

If it becomes clear in a few months’ time that the ordering process and testing are running smoothly, then the entire process through to NC programming is to be automated. Although LaserCloud is already technically capable of automatically transferring an online order to the NC program after the feasibility check and also entering it directly into the PPS, Joachim Deeg and his colleagues prefer to take another look at it themselves at the moment.

“Once we have the certainty that everything is running really smoothly, we will switch to automation here too. This will take us another step closer to paperless production,” he concludes.

Web:

www.optimate.de