In the Austrian town of Fulpmes in the Stubaital, where others spend their skiing vacations, the family business Schmid OG manufactures workpieces for the agricultural and automotive industries, among others, and in addition to plasma and laser cutting also offers powder coating and forging services. A compact laser cutting system rounds off the machinery in the cutting area and makes the small business something very special.

At the beginning of the 2000s, Gerhard Schmid founded the company together with his brother Karl Schmid. Both took over a chisel business that was over 100 years old and thus ventured into self-employment. The work quickly bore fruit. Over the years, the areas of powder coating and, through an investment in a used press brake, bending and punching were added to the service portfolio. Until then, Schmid OG was mainly a reliable partner for customers in the fields of agriculture, lighting construction and powder coating, but over time the family business also took on more and more tasks for the automotive industry. However, the cutting parts for the automotive suppliers always had to be purchased externally from a contract laser cutter in the region, which, however, withdrew after some time. “It was then quickly clear to us that we needed our own cutting system,” says Schmid.

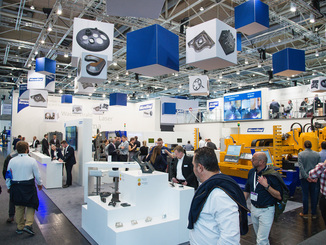

© MicroStep

Reduce dependencies

When selecting the right cutting solution, proximity to the manufacturer and German-speaking contacts were important criteria for the family business. One waterjet equipment manufacturer under consideration did not fit the bill with waterjet cutting technology in terms of materials, cutting speed and cost structure. So after intensive research, the company came across MicroStep and finally decided on a 2D plasma cutting system from the MasterCut series. This was put into operation in 2012 and took over a weighty part of the cutting tasks in the house with the cutting of steel in the material thicknesses from three millimeters to 35 millimeters, in some cases also up to 50 mm possible.

Laser machine for high requirements of the automotive industry

As the demands on accuracy for the parts of the automotive industry became higher and higher and could not be covered with the plasma cutting system, the idea arose to additionally acquire a laser cutting system. A move within the town in the Stubaital, including a new building in 2019, also created the spatial conditions for this – at least for a compact laser cutting machine.

Schmid OG did not have to think about the manufacturer of the additional cutting technology because of the good experience – it should definitely be a cutting system from MicroStep again. In April 2021, the two managing directors, Marie-Theres Schöpf and Gerhard Schmid, took a look at the MSF Compact series laser system during a demonstration at the CompetenceCenter South at MicroStep’s Bavarian headquarters. The system combined everything the company was looking for: an advanced, precise laser solution with a small footprint. Only two months after the demonstration, the father-daughter team decided to purchase the laser system. “We have again decided on a system from MicroStep, because everything has already gone well with the plasma system. From the system to the support,” says Marie-Theres Schöpf. “The support is great – you get a quick help right away.

It’s also just more convenient and straightforward to get software and equipment from one house.”

The system has been in operation since February 2022 and mainly cuts steel and stainless steel with sheet thicknesses from 1 mm to 12 mm. “We are very satisfied with the laser machine, which allows us to respond faster and more flexibly to customers.”

Web: www.microstep.com