![1_B35LS7M[3] The LS7 flatbed laser from the BLM Group for laser cutting metal can now be equipped with a 20 kW laser source. It is characterized by consistently high quality and accuracy of the laser cuts, extremely simple operation and ultra-fast pallet changes. © BLM Group](https://bbr.news/wp-content/uploads/2025/10/1_B35LS7M3.jpg)

With its presence at Blechexpo, the BLM Group followed on almost seamlessly from its in-house trade fair Innova 2025. The Group is bringing along some of the innovations for processing sheet metal and pipes that will be celebrating their premiere in Levico Terme.

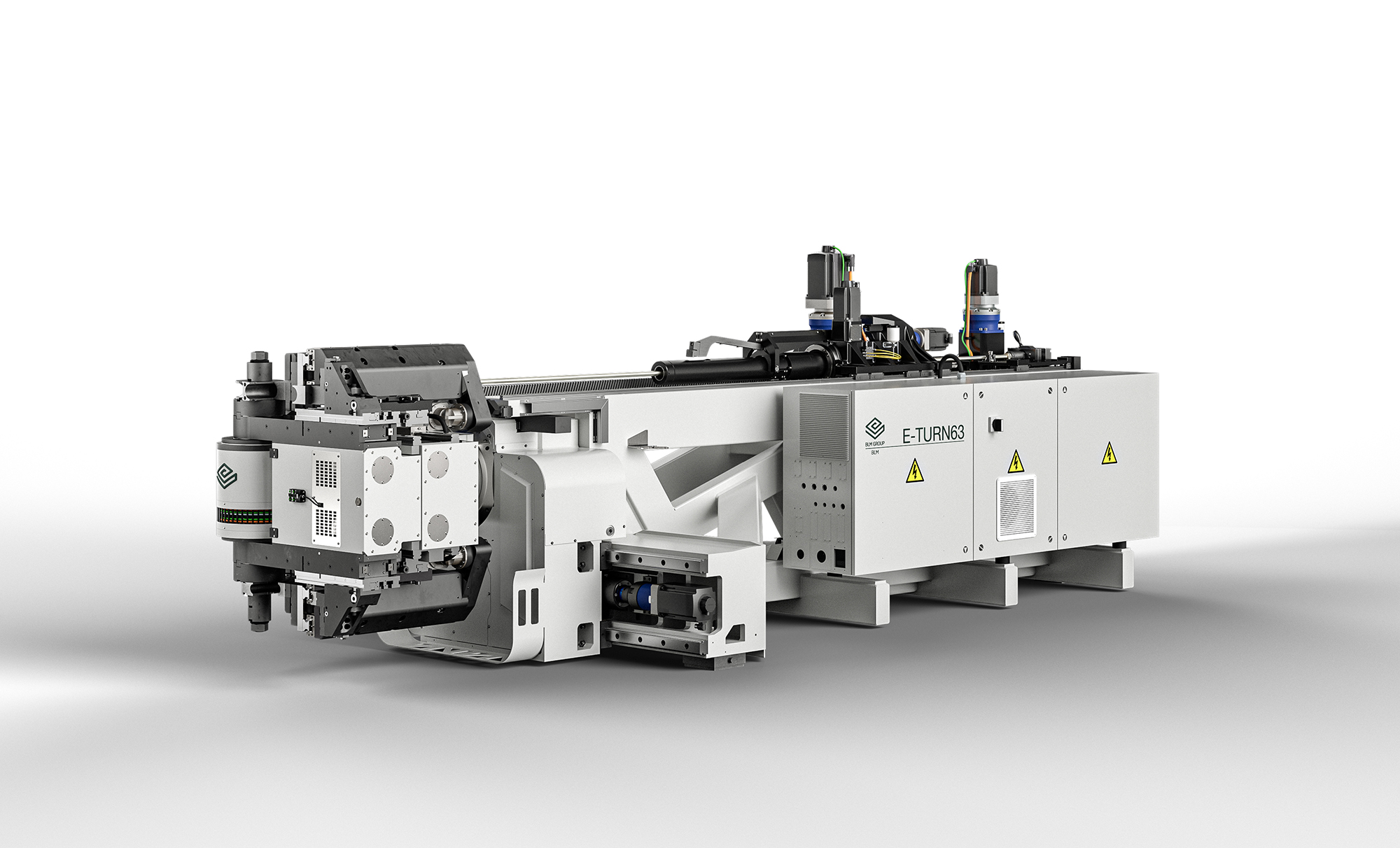

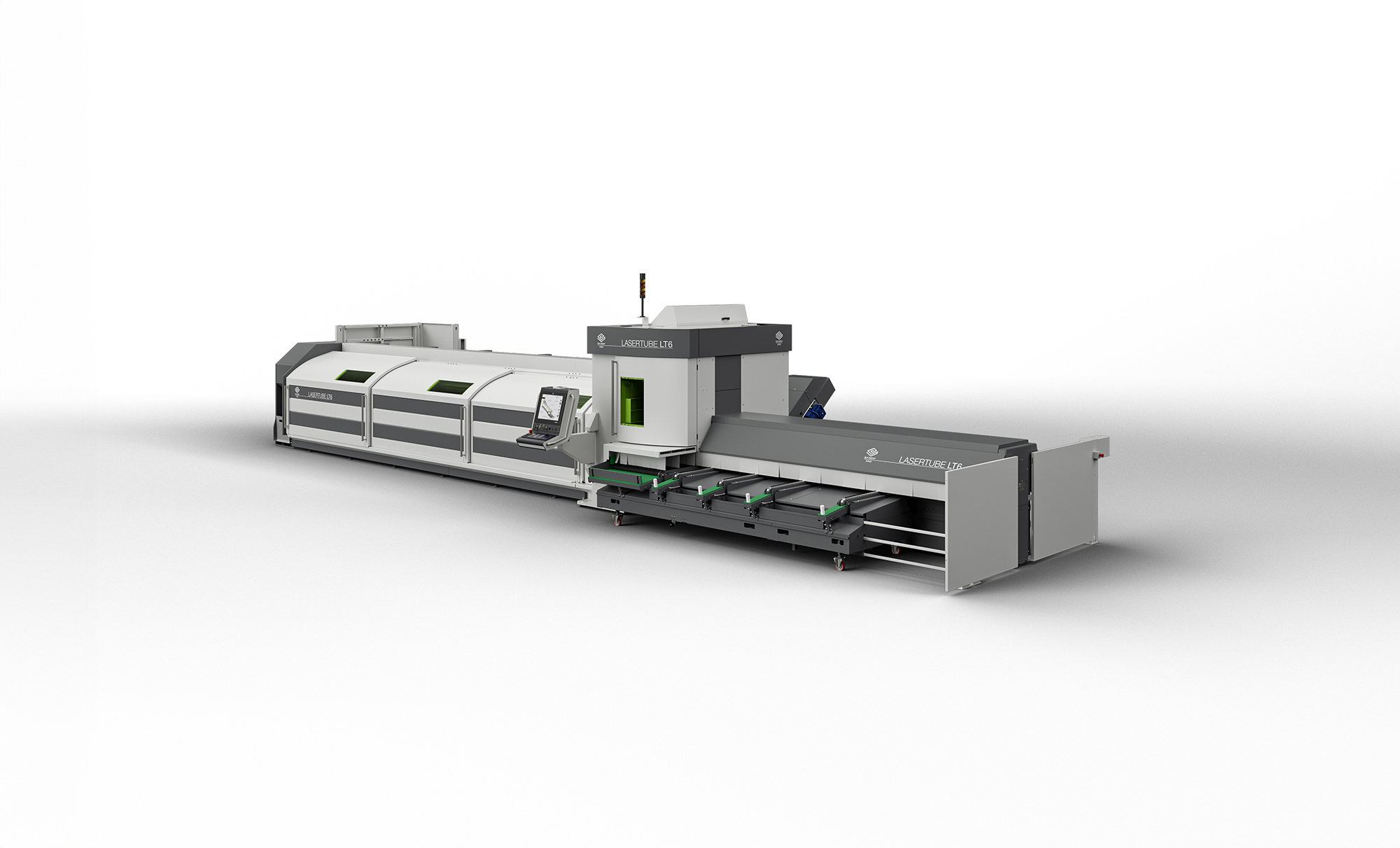

The new version of the LS7 sheet metal laser with a 20 kW laser source, the new E-Turn63 tube bending machine for right and left-hand bending of tubes with diameters of up to 63 mm in the process and the latest LT6 3D tube laser will take center stage at the BLM Group’s Blechexpo trade fair appearance in Hall 1 (Stand 1609). The latter combines technical performance with cost efficiency in a special way.

The company’s stand will also focus on its solutions for laser welding with robots, the integration of its various technologies and the automation of logistical processes around its machines – including loading and unloading as well as the transportation of materials between machines. These integrated and automated solutions allow customers to run unattended production around the clock.

However, the sophisticated possibilities of the software solutions developed in-house – which contribute significantly to the particular efficiency and flexibility of the BLM Group’s machines – will also be a topic at their stand in Stuttgart. The same applies to their intelligent services. Thanks to this comprehensive range of services from a single source, customers can produce even the smallest quantities profitably in their day-to-day business – with the shortest possible response times.

“Such a combination of seamlessly integrated machines for processing tubes and sheet metal, powerful, intuitive software solutions and customized service offerings is unique on the market. At this year’s Blechexpo, we will be underlining the benefits that this offers our customers,” explains Andreas Köster, Managing Director of the German sales and service organization.

© BLM Group

Extended possibilities in sheet metal laser cutting

The LS7 flatbed laser from the BLM Group for laser cutting metal can now be equipped with a 20 kW laser source. This version also offers the well-known features of this machine on the market: consistently high quality and accuracy of laser cuts, extremely easy operation and ultra-fast pallet changes. The LS7 processes a wide range of metal materials, including stainless steel, steel, aluminum and copper. It can be flexibly integrated into production processes and offers all the advantages of fiber sources, i.e. low energy consumption and maintenance requirements as well as the processing of highly reflective materials.

Its 2D laser cutting head automatically adjusts the internal optics to the thickness of the materials to be processed, while sensors continuously monitor the working conditions to guarantee perfect results. In addition, various options are available for the LS7 that automatically optimize the processing process and allow unattended production. This includes a compact storage tower, which allows free access to the pallet changer when required by lifting the loading pallet. This means that operators can load urgent jobs or materials that are out of the ordinary into the machine in between.

Additional options for bending pipes and thick steel bars

The new E-Turn63 tube bending machine is designed for processing tubes with large diameters of up to 63.5 mm and thick walls made from high-strength materials. It enables complex bends, which previously had to be produced from individual elements, in plant engineering, vehicle construction, shipbuilding, furniture manufacturing and many other industrial sectors. For example, this tube bending machine is perfect for the production of stabilizers, exhaust pipes, frames, load-bearing elements or heat exchangers.

The E-Turn63 can be configured with a wide range of functions for individual requirements – even retrospectively. This is a particular feature of its flexibility and helps customers when making investment decisions. For example, the tube bending machine is also available in a version without a mandrel bar. This can also bend thick steel bars to the right and left in the process and combines high bending performance with the convenience of an essential bending machine.

© BLM Group

Special price-performance ratio in tube laser cutting

The new LT6 combines high technology with a special price-performance ratio, which could make it an attractive solution for entry-level tube laser cutting. It focuses on user-friendliness and ergonomics. Automatic settings and a number of functions, including continuous adjustment of technical parameters, make the operator’s work easier. This ensures a high level of efficiency in production.

The flexibility of the 3D cutting head offers a wide range of options for producing visually high-quality joints from pipes and profiles with bar weights of up to 18 kg/m. It can make bevel cuts both at the ends and along the pipes and profiles, which significantly simplifies the subsequent welding work and minimizes the effort involved.

The high acceleration of the axis with the inclinable laser head in turn enables the machine’s high productivity in 3D cutting – whereby the optional ActiveTilt function combines the oscillating movement of the cutting head with the linear movement of the profiles to be processed, thus further increasing the speed of cutting and marking.

Background

The group includes the companies BLM S.p.A, Cantù (CO), specialized in the production of tube bending machines, forming machines, wire bending machines and 3D laser cutting systems, Adige S.p.A, Levico Terme (TN), specialized in the production of tube lasers (Lasertube family), sawing machines for tubes, solid material and profiles with brushes as well as measuring, washing and collecting systems, and Adige-SYS S.p.A, Levico Terme (TN), specialized in the production of sheet metal lasers and laser cutting systems for large tubes and profiles.

Web:

www.blmgroup.com