High-speed laser welding of large-format round batteries ensures economical production and helps vehicle manufacturers and users alike.

Design and construction of larger electric vehicle (EV) batteries promise several benefits to both automakers and owners. Manufacturers can enjoy more streamlined production and lower costs, and drivers can enjoy greater range, more power, shorter charging times, longer life and better operation in cold conditions.

© Coherent

Difficult battery production

There are several large-scale round battery designs from different manufacturers. Everyone makes individual demands on manufacturing, especially the joining processes. Some EV battery concepts contain integrated charge carriers that must be fitted very precisely into the insulating gel rolls, with very accurate control of the welding depth, otherwise there is a risk of damage to the insulating layers that could lead to a short circuit in the cell. Welding the contacts to the collector also requires careful control of the penetration depth. It is particularly important to limit the heat input into the battery during this process, as it could lead to melting of the polymer insulators.

Sealing the hoods is another connection process that was done by crimping for smaller batteries, but this does not scale well to larger cells and requires a new approach.

Current requirements

There are a number of welding processes used in the manufacture of rechargeable batteries, which vary depending on the manufacturer and design. However, the most demanding and sensitive procedures all have certain common requirements, including the following:

– minimum heat-affected zone

– Precise control of the burn-in depth

– Elimination of splashes

– high process speed (typically from 200 to 500 mm/s)

Some joining processes also require the welding of dissimilar metals.

Each of these requirements has been fraught with difficulties, and no single joining technique has been suitable for all processes. Consequently, manufacturers have pursued a variety of solutions. These include green lasers for welding copper (to overcome its low absorption of IR light) and laser-free methods such as US welding for joining foils to tabs.

The right laser for all joining processes

Coherent has developed a new type of laser that is more broadly applicable than any previous because, according to Coherent, the technology “offers an unprecedented level of control over how laser energy is delivered to the work surface – both in terms of spatial distribution and timing.”

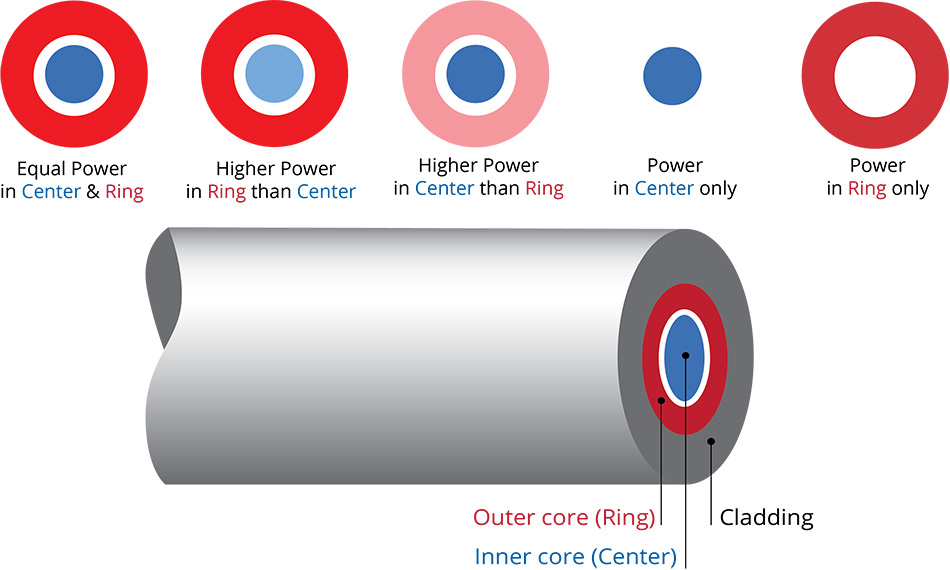

The key innovation is Adjustable Ring Mode (ARM) technology – a fiber laser whose spot consists of a central spot surrounded by a concentric ring of laser light, as opposed to traditional single spot power. The power of the point and ring can be controlled independently and even modulated.

The advantage of ARM technology is that it allows very precise control of the melt pool dynamics and thus more uniform and controllable machining, and prevents splashing. This type of laser is particularly suitable for welding copper, as the ring beam can be used to preheat the material, which significantly increases its absorption of infrared light. In addition, the option of a central beam with high power density ensures reliable coupling of the IR light into the copper. Together with the practical and economic advantages of fiber lasers, this makes the ARM fiber laser an alternative to green solid-state lasers for copper welding.

A single laser source that can perform so many different tasks offers manufacturers greater flexibility and cost-effectiveness. For example, the power of one laser can be used for several processes by beam softening. This streamlines and simplifies production.

Using a common type of laser at multiple points in the production process also reduces spare parts inventory and provides redundancy that helps reduce downtime for maintenance or repair.

Web:

www.coherent.com