Tool-independent system enables process optimization even before visible defects such as cracks or wrinkles appear.

Deep drawing is a particularly demanding process in sheet metal forming, especially for high drawing depths and small radii. If too little material flows in during the process, thinning and cracks may occur in the component; if too much material flows in, wrinkling may be an undesirable consequence. The material remaining after the forming process – the so-called flange or drawing edge – is therefore directly related to the component quality. Schuler has therefore developed a drawing edge monitoring system that helps to assess part quality immediately.

“Reducing scrap is a top priority for our customers – not only to save costs, but increasingly to meet sustainability goals,” explains Michael Werbs, Director of Edge Solutions. “Schuler is making an important contribution to this with this development.” The application is already in use in this form at the Smart Press Shop, the joint venture between Porsche and the school in Halle (Saale).

Forming simulation allows the drawing edge at critical points to be determined in advance and compared with the values determined in practice. The associated data is stored in a database together with a unique identification number for the component. Based on the knowledge gained in this way, modifications can be made to the process, such as changes in oiling or drawing pad forces, even before the components show visible quality defects such as cracks or wrinkles.

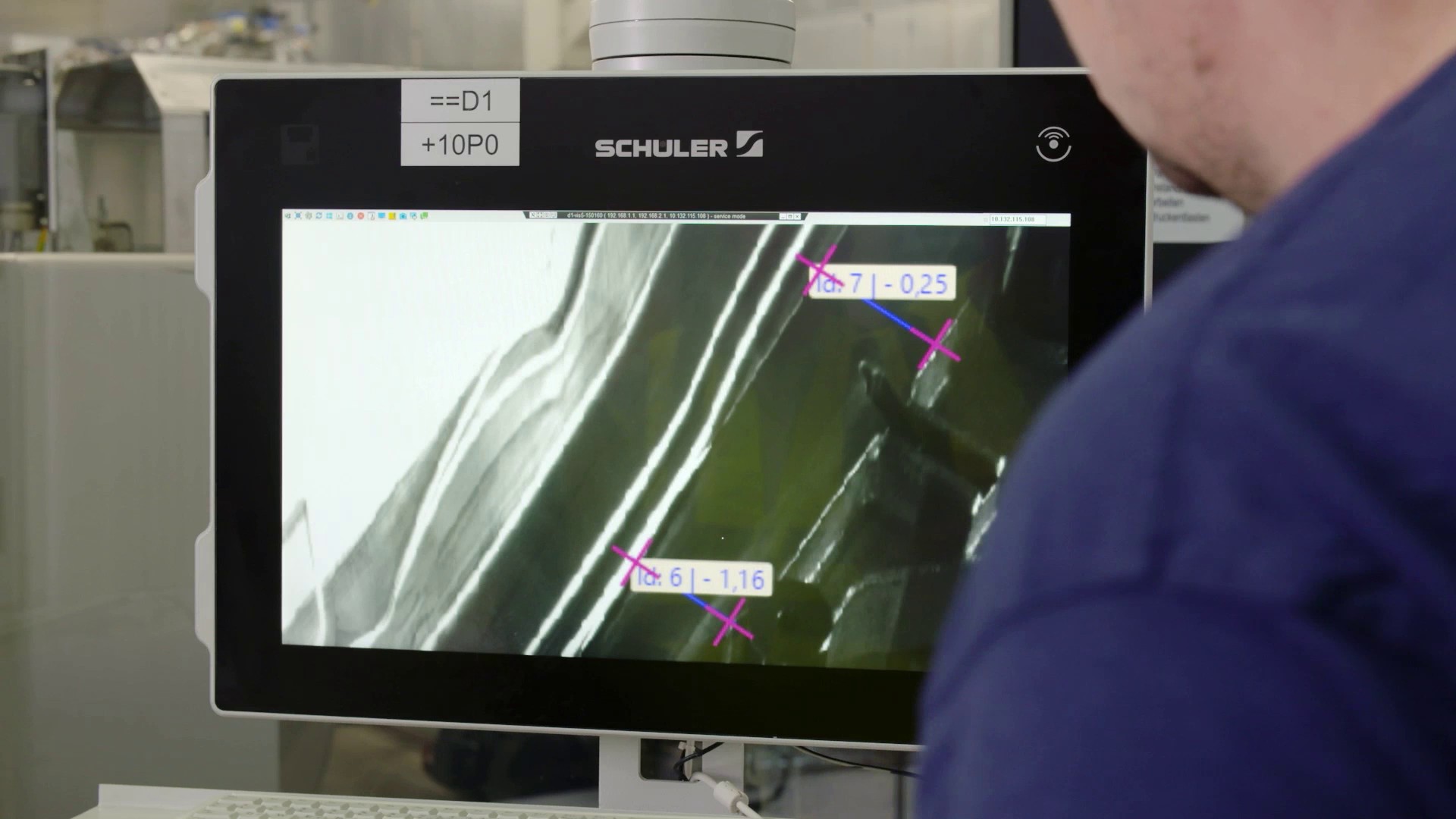

Until now, this required special tools that had elaborately integrated measuring systems for the material flow and needed additional connections for this. The drawing edge monitoring system developed by Schuler is based on cameras mounted in the press room, which is why the system works independently of the die and can monitor the drawing process in all dies that are run on the line. Within fractions of a second, the system provides information on whether a good part has been created or not.

Web:

www.schulergroup.com