Gas-shielded welding with the appropriate industrial welding robots is now also brought together by Kuka in intelligent, modular cell concepts.

“Nothing is more powerful than an idea whose time has come,” the French writer Victor Hugo is said to have once said. But is that really true? The search for traces leads to Lower Bavaria. On the outskirts of Massing, where Stela Laxhuber GmbH set up its administrative and production units in a state-of-the-art industrial area five years ago.

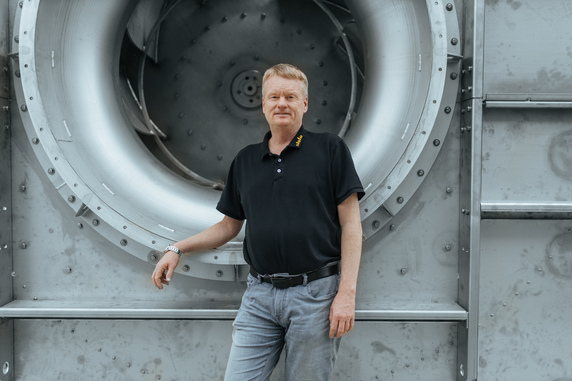

The family company, which is now managed by Thomas Laxhuber in the third generation, is a “hidden champion” among plant builders. For customers from all over the world, Stela – named after the founder Stefan Laxhuber – with 235 employees designs and manufactures sophisticated drying systems in all conceivable sizes and fields of application. The buyers for this come from all over the world, including from agriculture, wood-based materials processing, the food, animal feed, pulp and paper industries or from the water industry.

Large-scale drying

The heart of such drying systems are huge fans that set a flow of warm air in motion to remove moisture from products such as grain, corn, wood or recycled plastic. This makes them durable and creates the conditions for their further processing. The fan wheels in the dryers can have a diameter of 1.60 meters and weigh half a ton. When such a colossus is accelerated to 3,000 revolutions per minute, top processing of all joined components is an absolute must.

“The specialty at Stela is the high level of vertical integration,” emphasizes Thomas Laxhuber, who in 2014 took over the management of the company in the third generation from his father Stefan, the son of the founder of the same name. “In order to continue to produce the world’s leading drying technology, we want to manufacture the essential components of our machines ourselves as far as possible. We see this as an essential prerequisite for the best possible quality and a long service life of the systems. ” This is particularly true for highly stressed components such as the fan wheels. These centrifugal fans are comparable to a rotating drum. With their curved blades they suck in the air via the motor axis and blow it out again offset by 90 °.

Missed early start

25 years ago, Stela was already looking for automation solutions for fan assembly. “Back then we wanted to set up our welding shop with robots of a different design,” reports Thomas Laxhuber. “But the experiment had crashed. The robots couldn’t really help us with demanding welding tasks, created more problems than they solved and found almost no acceptance among the workforce. The idea was good, but the time wasn’t right. We have abolished the robots again. “

Today, Andreas Utz stands with a smart pad in front of a 40 square meter, container-like housing in the middle of the production hall and looks inside through the dark green protective glass pane.

The fan production manager at Stela controls the brand new Cell4_arc robot cell from Kuka. Inside it flashes and sparkles blue, it crackles, white smoke rises. The six-axis Kuka inert gas welding robot of the KR Cybertech type moves its slender orange arm rhythmically and guides the sensor-controlled torch to the fan drum.

Andreas Utz had previously attached the blades to the housing by hand with spot welds and screwed the steel structure onto the positioner. After the positioning unit was swiveled inside the cell, an intelligent line laser first scanned the component using what is known as “Kuka.SeamTech Finding” and determined the optimal starting point for the burner. Then the tricky millimeter work could begin. Seam by seam – always with the same precision, choreographed by the Kuka.ArcSense software.

time is money

In about 50 minutes the centrifugal fan is welded and ready for balancing and painting. When the finished workpiece is moved out, the next workpiece screwed on by Andreas Utz on the other side is already turning into the cell. “Work in progress”, says Utz with a smile. “Welding by hand takes around a day. With the robot cell, we are now in the fast lane in production. In terms of time and quality. Because the weld seams fit so perfectly in a short time that cannot be done by hand. Now we are producing in quantities that we would never have dreamed of and were able to master the order situation again. “

The way to make work easier was not as easy as operating the cell. Sven Pietsch still remembers the negative reactions from the robot suppliers when the Stela Purchasing Manager and Managing Director Thomas Laxhuber set out to look for a new approach to automation after 25 years. “We were under pressure,” recalls Pietsch. “The order books were full and at the same time it was becoming increasingly difficult to find suitable specialists for our demanding but also comparatively monotonous welding work in large-scale production.”

At various trade fairs, the people of Lower Bavaria were looking for suitable solutions for their requirements and were repeatedly thrown off the mark. “Apparently, as a medium-sized company, they thought we were too insignificant,” says Sven Pietsch with a smile. “Until we met the Kuka experts at the stand at the Euroblech in Hanover. Here we very quickly got into conversation about a tailor-made solution for our challenge. That was an intensive exchange at eye level. ” And a learning curve for everyone involved, as Thomas Laxhuber adds.

Soon after, in the TechCenter for welding applications from Kuka, they immersed themselves deeply in Stela’s production processes and configured the Cell4_arc robot cell, which is perfectly tailored for fan production, from various available standard modules – with all hardware and software. “At all times, we had the feeling that we were dealing with the right people and the right technology at the right time, in the right place,” states Thomas Laxhuber.

A well-made cell concept

The robot cell for Stela describes a new path to customer-specific, modular automation steps for Kuka as well. “With our intelligent Kuka Cell4_production concept, we can combine perfectly coordinated components and proven standards from the field of inert gas welding with our customers to create ideal solutions in welding automation. With the right application software, the handling and programming of the welding parameters are as easy as possible and help to meet the highest production demands, ”says Mathias Klaus, responsible for“ Solution Sales Modular Cell Business ”at Kuka. “The robot cell that we developed together with Stela is impressive evidence of this.”

Thomas Laxhuber also likes that. “It has been part of the Stela DNA for almost 100 years that we are guided by quality in the world of drying and that we are always one step ahead technologically. The future can be built on this. Anytime.” Even if a good idea has to mature for 25 years to develop its full power and strength in the right partnership at the right time.

Web:

www.stela.de