Politicians and industry are longing for increased hydrogen use and have long since set out to find a solution. Not only must the production and storage of H2 be ensured, but its transport must also be regulated so that the hydrogen reaches the point of use from the point of production. However, a high level of investment will be required for hydrogen storage and transport routes. The pipe industry, which already offers suitable technologies and materials, is in demand. So there’s a lot in the pipeline …

© VNG AG

Europe plans to be CO₂-neutral by 2050. Hydrogen will play a decisive role in achieving climate neutrality – in several respects. As a storage medium, it can be used to balance out fluctuations between energy production and consumption that occur when using renewable energies. In addition, the use of green hydrogen makes industry CO₂-neutral – as in steel production, for example. In each case, an infrastructure of pipelines and plant technology is necessary.

Safe hydrogen transport will play a central role in a renewable energy mix – and the pipe industry is already H2-ready. For example, Mannesmann supplies steel pipes designed for transport and storage. For H2 transmission – in pipelines, for example – the inner surface is manufactured free of surface heels. Internal points of attack for the hydrogen are kept to a minimum by undercutting the phosphorus and sulfur content – compared to the EIGA guideline. “A further lowered carbon equivalent ensures excellent weldability of our pipe material,” emphasizes Mannesmann. This ensures a long service life.

Pipe industry ready for the H2 market

Together with steel distribution partners, Benteler Steel/Tube supplies the Benteler Hyresist product family, which includes seamless, hot-rolled tubes and meets the requirements of the European Industrial Gases Association (EIGA) for tubes for distribution networks. The criteria are: hydrogen-compliant steel analysis, pressure resistance, and homogeneous structure. With an outer diameter of 21.3 to 141.3 mm, the dimensional range of the Benteler tube solution meets the current specifications for hydrogen lines. “In addition, optimized mechanical values and the high purity of the steel materials used prevent hydrogen embrittlement,” the company explains.

Butting is also ready for the H2 pipe market. Vacuum-insulated transfer lines could save time and resources compared to conventionally foam-insulated pipes, according to the company. The cost-effective transfer of liquefied natural gas and liquefied hydrogen LH2 (LNG) requires pipeline systems of much larger dimensions than is the case for other cryogenic liquids, he said. This allows smaller pipe diameters to be selected, reducing the amount of material required. In addition to standard lines, the company’s expertise includes transfer systems for trailers (helium and hydrogen), hydrogen systems for the automotive industry, and refueling systems for the aerospace industry (hydrogen and oxygen).

Important hydrogen projects

It is currently important to act with foresight. In Wolfsburg, for example, two state-of-the-art gas-fired power plants will secure the energy supply for the VW plant and the city of Wolfsburg. “To ensure that they can also be operated with hydrogen in the future, Mannesmann H2ready pipes from Mannesmann Line Pipe were already used in the construction of the supply line,” explains Mannesmann. The almost 1,900 pipes have individual lengths of up to 18 meters in L360NE grade and a predominant diameter of 406.4 mm. The route runs parallel to an existing pipeline and was laid over a length of nine kilometers without trenching and therefore particularly gently. For this purpose, the tubes were additionally wrapped with GRP.

For the connection of the LNG gas terminal in Brunsbüttel to Hetlingen, Salzgitter AG subsidiary Mannesmann Grossrohr GmbH (MGR) is supplying pipes with a diameter of DN 800 for a total length of around 54 kilometers on behalf of Gasunie Deutschland. The approximately 3,200 pipes are specified “so that hydrogen can also be transported through the pipeline in the future,” MGR explains. Commissioning is scheduled for the end of 2023.

A current sensational construction project is the connection of the Wilhelmshaven LNG terminal with H2-ready steel pipes from Mannesmann Line Pipe on behalf of the energy network operator Ewe Netz. With around 16,000 t of H2-ready pipes, Mannesmann is contributing to the expansion of the LNG infrastructure in northwestern Germany. In total, the company will supply around 4,100 pipes in the DN 600 size range in lengths of 18 to 12 meters. The pipeline is scheduled to be commissioned at the end of 2023.

© thyssenkrupp Steel Europe AG

More climate-friendly steel production

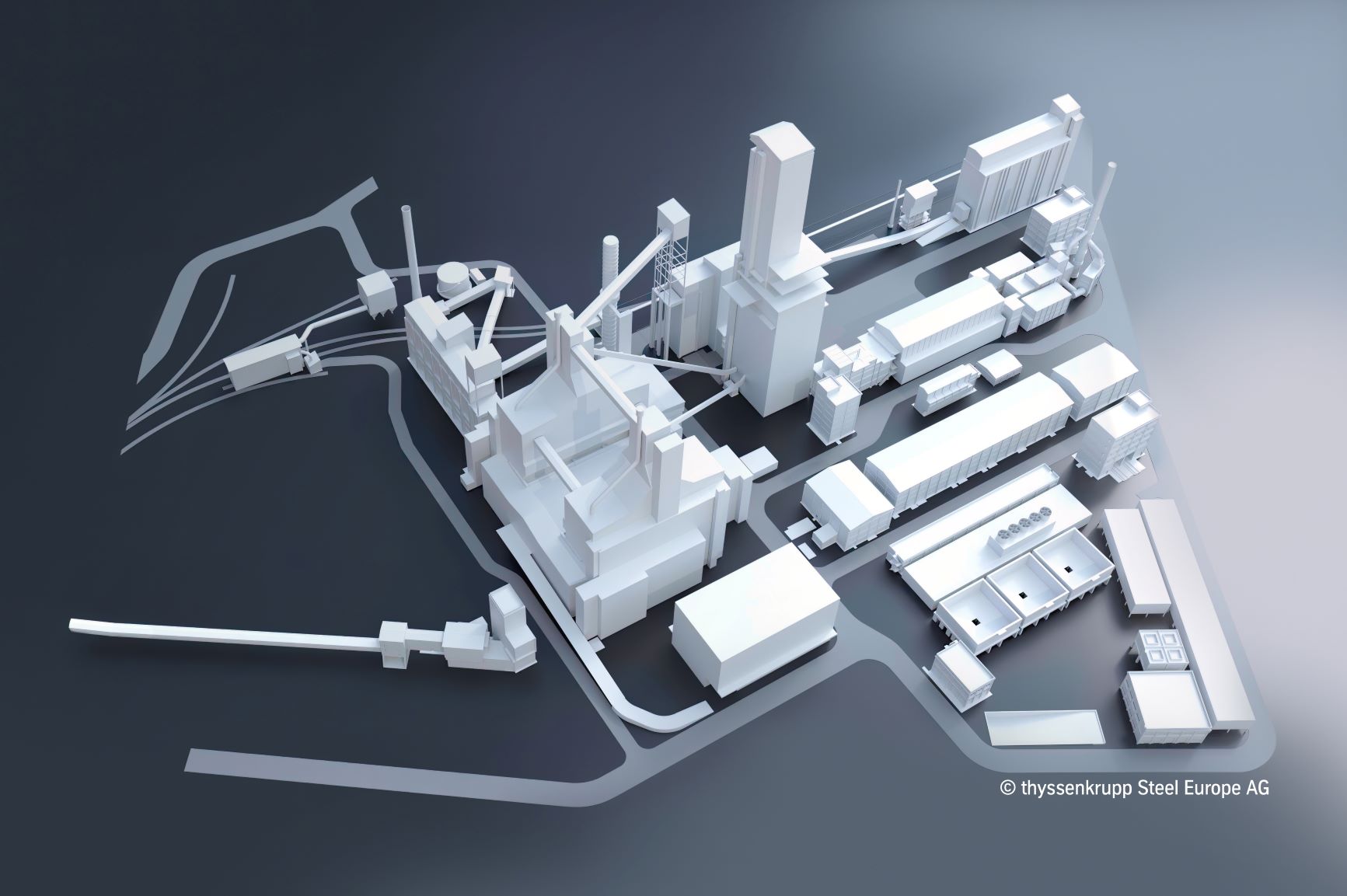

The production of pipes for hydrogen transport requires H2-optimized steels for safe and durable pipeline transport systems, which thyssenkrupp also supplies. In addition to the low-alloy steel grades X42 and X52, which are suitable for transporting gaseous hydrogen and hydrogen mixtures, the Group has optimized material concepts for the strength range up to X70. “These steels are optimized with regard to the expected standard requirements of longitudinal and spiral sewer pipes for hydrogen transport, in particular with regard to restricted contents of carbon, phosphorus and sulfur,” thyssenkrupp explains.

The production of steel is also to become more climate-friendly with the aid of hydrogen. thyssenkrupp Steel is therefore investing in the decarbonization of its steel production, which in turn will also improve the ecological balance of steel tubes. The Group therefore commissioned SMS with the engineering, supply and construction of a hydrogen-powered direct reduction plant, two melters and associated auxiliaries at the Duisburg site. This is one of the world’s largest industrial decarbonization projects with an order volume for SMS alone of over €1.8 billion, and commissioning is scheduled for the end of 2026.

H2 infrastructure needed

With Salcos (Salzgitter Low CO2 Steelmaking), Salzgitter is working together with partners from industry and research to lay the foundations for virtually CO2-free steel production. Central elements of the program are electricity from renewable sources and its use in the production of hydrogen by electrolysis. “This green hydrogen will replace the coal we currently use in the conventional blast furnace process,” the group explains. This is possible with the aid of direct reduction plants, in which iron ore is reduced to iron directly in the solid state by hydrogen. With this technology, water vapor is emitted instead of CO₂.

There is much to be done: Germany, for example, is not sufficiently prepared for the ramp-up of the hydrogen economy. This is the result of the H2 balance, an analysis by the energy company E.ON based on data from the Institute of Energy Economics at the University of Cologne. “Looking ahead to 2030, it turns out that neither the domestic production capacity of green hydrogen is sufficient, nor can the German import demand be met.” In addition, the infrastructure is still lacking. This is now also a challenge for the pipe industry. It is ready for implementation.

Innovations from this industry will be on display at the leading international trade fair Tube from April 15 to 19, 2024, at the Düsseldorf exhibition center.