With the third generation of all-in-one reduction machines for single or double-thickness spokes – for e-bikes and cargo bikes, for example – Amba has further increased the straightness of the finished spokes. The new systems produce up to 40 pieces per minute.

Aachener Maschinenbau GmbH

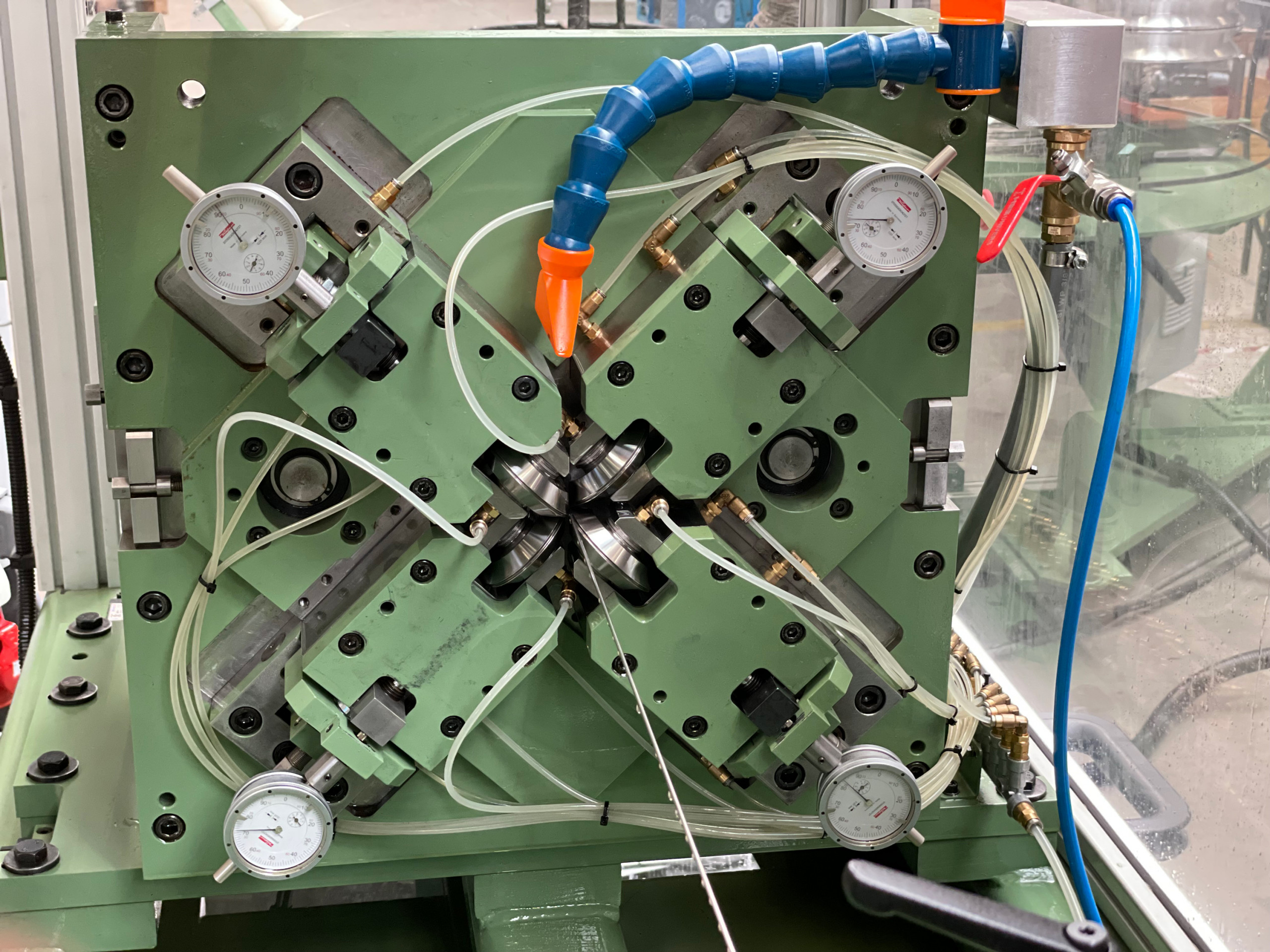

A new feature is that the rotary straightener is now positioned after the reduction and drive system and before the cut-off. In this way, Amba ensures that no transverse forces act on the wire after forming and during feeding and that it maintains the exact straightness with which it leaves the straightening unit. At the same time, they achieve a roundness tolerance of just two to three hundredths of a millimeter.

Georg Haas, Sales Manager at Amba, is currently seeing an increasing demand for the reduction machines: “The boom in e-bikes and cargo bikes means that the demand for thick-end spokes is constantly increasing. Compared to bicycles without a motor, spokes have to withstand significantly higher mechanical loads, because not only are people generally riding faster, but heavy loads are also being transported more and more often. The spokes therefore have to transmit significantly higher forces, especially when braking.”

Single-thickness spokes with a large diameter at the hub and two mm diameter at the rim are currently in high demand. They allow manufacturers to meet the requirements for higher hub torque while continuing to use standard components for the rim. Double-thickness spokes, which are thinner in the middle than at the ends, are mainly used for high-end bicycles. They save weight and reduce flow resistance.

Aachener Maschinenbau GmbH

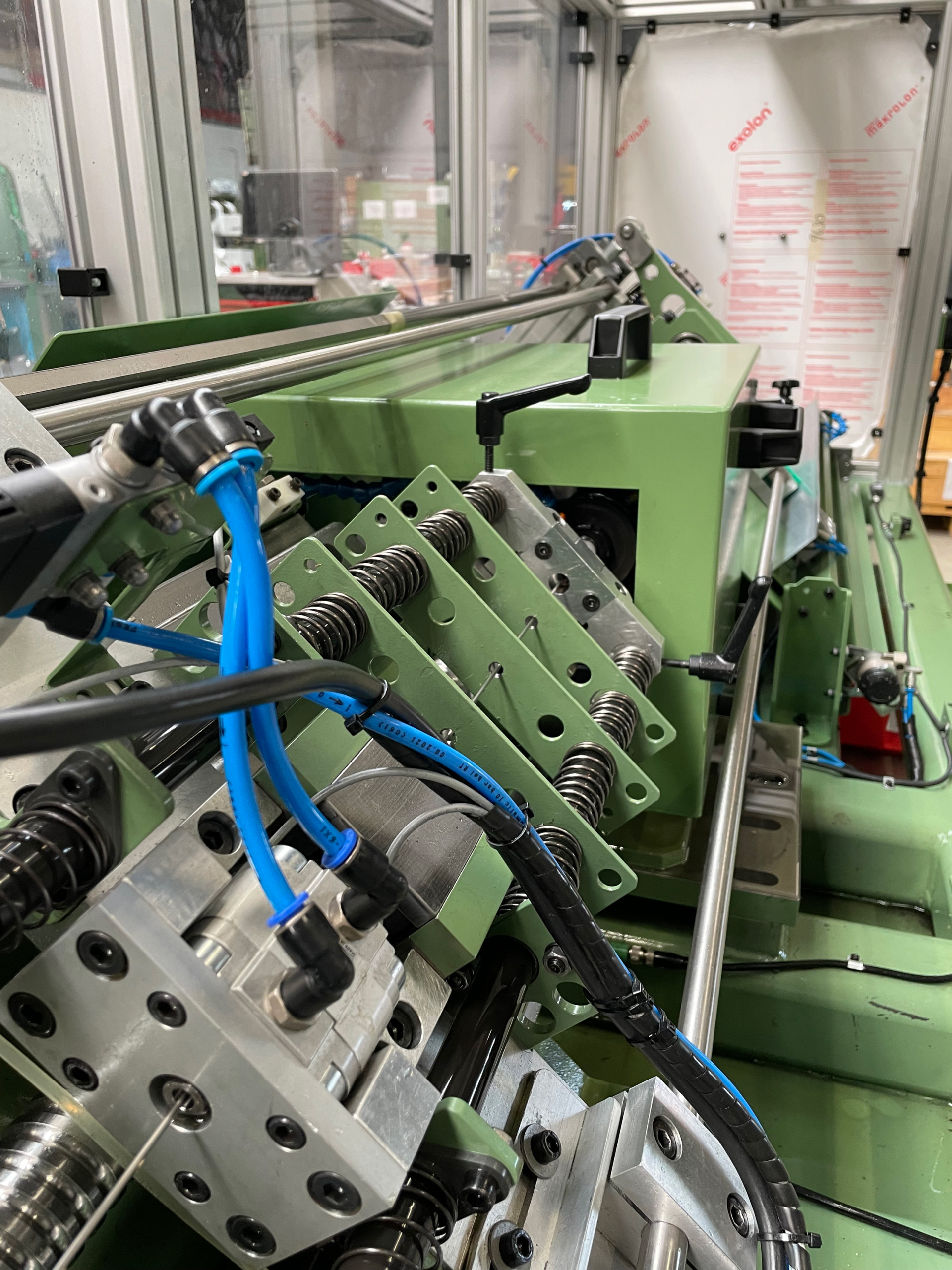

Like all Amba machines, the new DD 350-III reducer is an all-in-one machine. All process steps from uncoiling the coil to the finished blank take place in the same system. With servo-controlled forming rollers, which we are the only manufacturer to use, the distance between the rollers is controlled as the wire passes through. In this way, the diameter of the blanks is brought to the specified dimension along their entire length. If the wire is cut in the thick area at the end of the process, double-thickness blanks are produced; if it is cut in the transition area, single-thickness spokes are the end product.

By the way: No steel below 1200 N/mm² has a chance of being processed into spoke wire. 1800 N/mm² are by no means unusual.

Web:

www.amba.de