The first trade fair is a kind of trial by fire for many start-ups. Does the product reach the target group? Is his innovative approach evident? Does the pricing fit? The founders of Optimate can answer all these questions with a clear “yes” after Blechexpo: Their digital component optimization met with enormous approval in Stuttgart – as did the innovative algorithm announced for 2022.

This is apparently what many in the sheet metal working industry have been waiting for: an online platform that identifies rule-based design errors in components at an early stage and also shows the user how to reduce material waste and production costs. “Very pleased”, says Managing Director Martina Trinczek about the lively activity at her stand at Blechexpo. This was integrated into the trade fair presentation of the technology company Trumpf, from which Trinczek spun off Optimate with Jonas Steiling in the summer of 2020. “The many conversations we’ve had have shown that our current three-tier offering is exactly what the market needs.”

© Optimate

With their portfolio, the young founders address small as well as (medium) large companies: While up to 50 parts per month can be optimized with the “Starter” license model, the “Advanced” package also allows companies with a monthly optimization requirement of up to 200 parts to use the repair mode and a history of potential detections. The “Enterprise” package is aimed at contract manufacturers with their own web shop and online marketplaces.

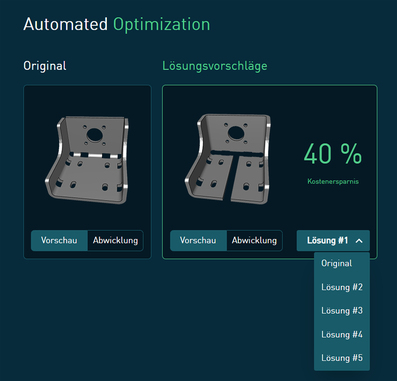

Fully automated optimization of components without rule-based design errors

The prototype for a new algorithm attracted particular interest at the fair and has given the development a tailwind. “After the tremendous response to the preliminary version, we are now moving on to the elaboration so that we can enter the phase with test customers and then make the offer available as quickly as possible,” Trinczek said.

Its co-founder and co-managing director Jonas Steiling explains the principle: “Currently, we succeed in detecting and correcting common design errors with the help of artificial intelligence. With the latest product development, correctly designed components can be optimized in a fully automated way and cost savings can be shown. With one click, the user is shown several solutions for optimizing the sheet metal part – and it is up to him to decide which variant is currently the best for him.”

This adds another dimension to sheet metal part optimization with Optimate, making it even more efficient and sustainable by helping to save material, costs and energy.

Optimate GmbH is an independent spin-off from the high-tech company Trumpf based in Stuttgart. Founded in 2020, the company specializes in the digital optimization of sheet metal components using artificial intelligence. The current subscription offer covers individual optimization needs (up to 50, 200 or from 500 parts per month), reveals rule-based design errors and shows the optimization potential. In the higher levels it also offers a repair mode, a history of potential detection as well as an API interface and export of the 3D data. The founders want to enable small, medium and large sheet metal manufacturers to design more sustainably, reduce costs and manufacture more efficiently. In 2022, a new algorithm is to be launched on the market that will show companies the optimization potential of sheet metal parts that have also been correctly designed on the basis of rules.

Web:

www.optimate.de