People around the world are still exposed to many safety and health risks from their work. Therefore, on April 28, 2022, the “World Day for Safety and Health at Work” was held again. The topic is, of course, just as relevant today.

The Day of Action was established back in 1984 by the International Labor Organization (ILO) to promote safe, healthy and decent work. The ILO estimates that about 6,000 people worldwide die every day from work-related accidents or diseases. Occupational safety and health are therefore a concern for governments, companies and employees.

Accident prevention and protection of workers must be further advanced through various measures, means and methods. In this context, occupational health and safety deals, among other things, with the prevention of occupational accidents, the reduction of their consequences, health protection and personal protection at work. Wherever in the world metals are processed by welding, cutting or grinding, the main concern is clean air that is not harmful to health as a basic right of employees.

Invisible danger – fine dust

The challenge: to combat particulate matter as an invisible danger. Fine dust is generated directly during welding. It consists of minute solid and liquid particles, which are divided into different particle fractions. Particles with a diameter of up to 10 μm (PM10/PM = particulate matter) are referred to as fine dust:

– Particles of size around 3 to 10 μm are deposited in the nasal and pharyngeal cavities.

– Particles around 2.5 μm (PM2.5) are respirable.

– Particles smaller than 1 μm (PM1) even enter the bloodstream via the alveoli.

The health effects are enormous, ranging from irritation and inflammation of the mucous membranes to damage to the alveoli and plaque formation in the blood vessels. According to WHO, sustained exposure to fine particulate matter (PM2.5) can lead to atherosclerosis, affect births, and trigger respiratory diseases in children. The Federal Environment Agency estimates that about 47,000 deaths a year in Germany can be attributed to particulate matter. Depending on the welding processes and materials, welding fumes with fine dust therefore pose a high potential risk to the health of welders.

Metallic smoke

The smoke particles here are generally smaller than 1 µm or predominantly even smaller than 0.1 µm (ultrafine dust particles). All welding smoke is thus alveolar. When inhaled, it penetrates deep into the alveoli (air sacs) of the lungs and settles there. Here, the particles have a lung-damaging effect at best. Often, however, they are toxic, as in the case of copper, manganese or zinc oxide, for example. Inhalation of welding fumes from processing chromium (VI) compounds, lead, titanium or nickel oxides can even lead to cancer.

Throughout Europe, legislators have enormously raised the standards for healthy indoor air against the background of this health burden. In addition, a higher level of health awareness is being implemented in more and more companies. Promoting employee health is a high priority, also in view of the increasing shortage of skilled workers and the growing sensitivity to sustainability issues.

“Health standards in manufacturing companies where welding fumes and dusts are generated have increased enormously. Modern filter and extraction systems and the latest filter media make it easier than ever to ensure clean air beyond the legal requirements, especially in welding and cutting,” says Teka Managing Director Simon Telöken. “Especially in times of crisis, companies should not put off investments in the area of health protection and prevention, for which subsidies are sometimes available,” recommends the managing director.

Play it safe – W3-certified devices

When purchasing new equipment, companies are on the safe side if they look for test marks such as W3 certification, which Teka offers for almost all of its extraction and filtration systems. This test mark is awarded by the Institute for Occupational Safety and Health to systems that meet the highest requirements, for example with regard to volume flow, positionable extraction hoods, spark pre-separators, etc., and that separate at least 99 percent of the welding fumes drawn in.

Occupational safety – common cause

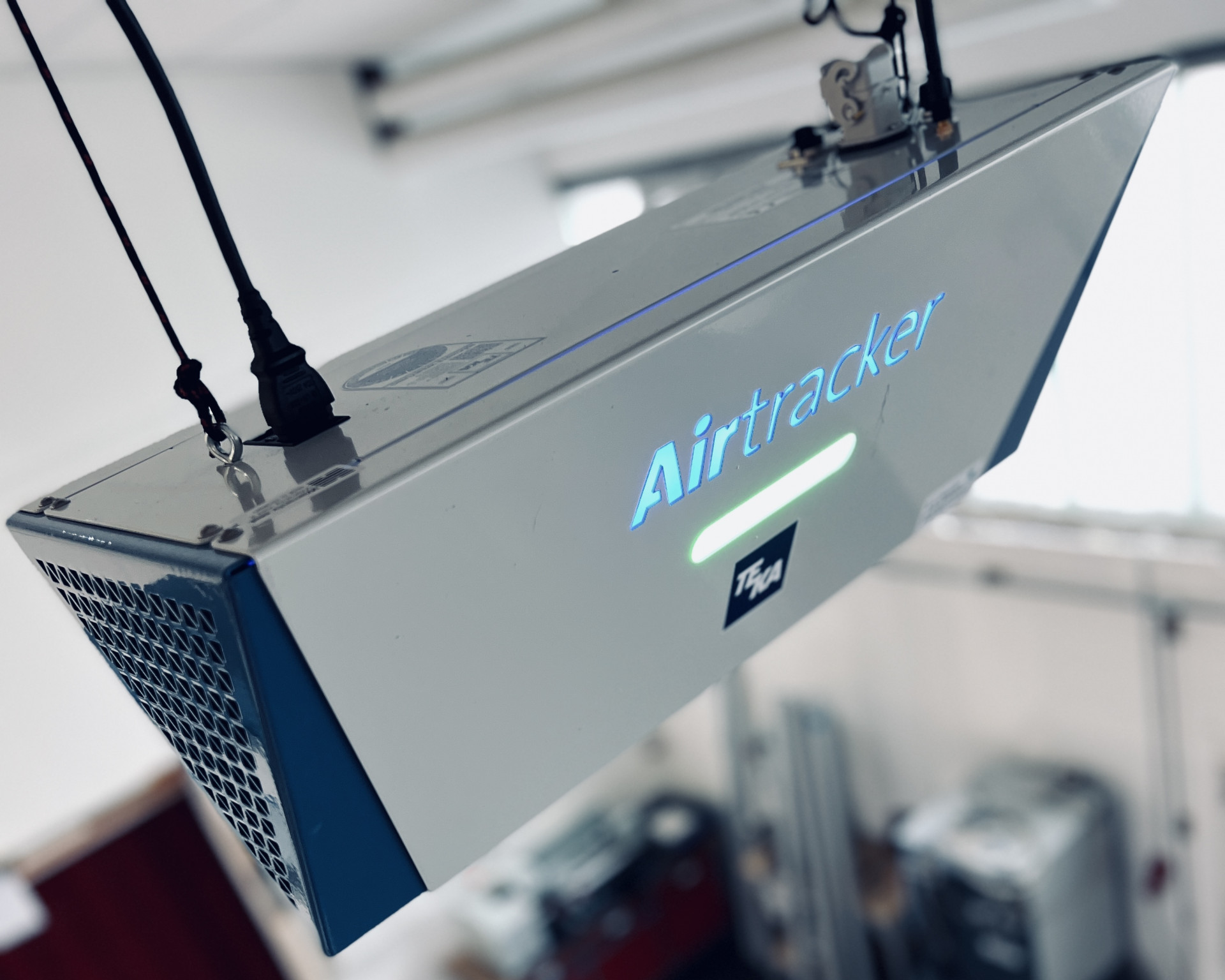

Occupational health and safety must be placed directly with management and anchored at all management levels. However, employees in the metalworking industry can also exercise their duties to assist the employer with occupational health and safety measures. “In addition to wearing personal protective equipment, this can also include, for example, room air monitoring, which ‘intelligent’ systems such as the Airtracker make easy with their traffic light signal function,” adds Simon Telöken.

About Teka

Teka Absaug- und Entsorgungstechnologie GmbH has been one of Europe’s leading manufacturers of extraction and filtration systems for industry, trade, crafts and laboratories for 25 years. As a reliable partner and expert for clean air in the workplace, Teka supplies international medium-sized companies and corporations from the metalworking industry, the electrical industry and laboratory technology. Teka systems ensure healthy indoor air and thus comprehensive health protection for employees and contribute to environmental protection.

The product range includes serial mobile and stationary systems, special designs as well as complex system solutions for the cutting industry and the VAC series for powerful burner-integrated extraction. The product portfolio is supplemented by cutting, welding and flame-cutting tables as well as visual and sound protection.

The Viroline series offers effective protection against viruses, bacteria and fungi and reduces the aerosol concentration of the room air. Around 150 employees work hand in hand in development, production and sales to offer tailor-made solutions internationally with intensive consulting, service and installation services. Almost all Teka products meet the safety requirements for the highest welding fume separation class and have been awarded the “W3” quality certificate in accordance with DIN EN ISO 15012-1. Teka is a successful pioneer in the field of Industry 4.0, as the company proves with the Airtracker family for digital room air monitoring and SmartFit boxes for plant networking. Through its active participation in the Industry Business Network 4.0 (IBN 4.0) association, Teka is committed to the development of plant standards.

Web:

www.teka.eu