Do you remember the “eternal”, unaccustomed standing at the vice, filing at a U-piece. You should get a feel for the material – St 37. And you got it, tenth by tenth. A few weeks later at the “lathe”, the resistance of the metal was felt again, but only a little. Even just a little bit distinguishes a spinning lathe from a turning lathe, but the resistance has other reasons.

© Abacus

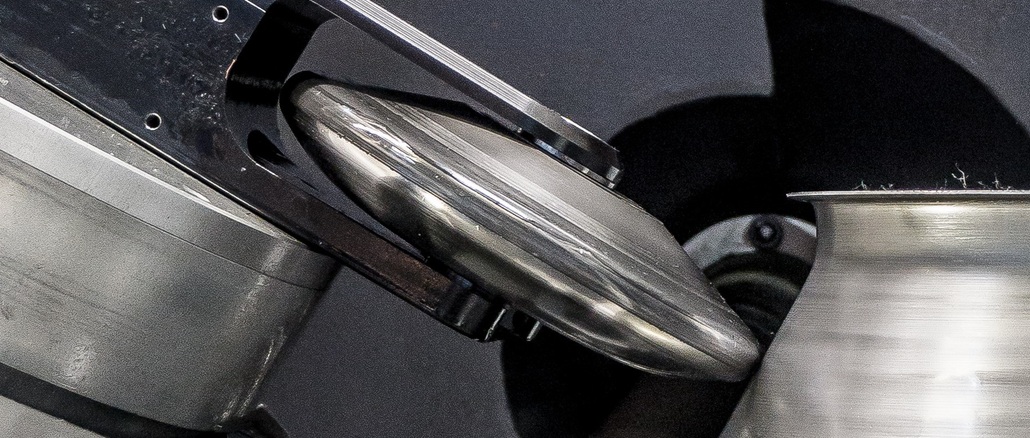

CNC machines have long been the standard for the production of rotationally symmetrical hollow bodies – as is the case with the Premo spinning machines from Abacus Maschinenbau. Customers of the Osnabrück-based think tank praise the high reliability and precision of the systems – but many would also like to see the return of a haptic component that characterized what used to be a decidedly manual process. Abacus has now put this customer feedback into practice by developing a new operating unit.

With the world’s first Premo-Force feedback control, Abacus now returns the desired haptic element to the hands of the user, combining technical perfection with the possibility of directly “feeling” the machining of the metal rounds through a more “immediate” contact with the product during the potting process.

“Spinning as we know it goes back to a long tradition in which the skilled handling of a rod – also called a spoon – played an important role. The pushers used the metal mandrel at the end of the rod to deform a rotating sheet of metal and, with great skill, brought it into the desired shape. In the process, the force and vibrations were transmitted directly to the hand and body of the operator. In this way, a special feeling for the forming process developed in that the operator constantly felt the resistance and was thus able to exercise direct control over the forming process,” Dipl.-Ing. Derk Weber, one of the two managing directors of Abacus, explains the background.

© Abacus

Resistance at the pressure roller transfers proportionally to the control system

Because the goal today is usually high quantities with absolutely identically reproduced spinning results, CNC machines have long since taken over this work. According to Abacus, this should remain the case. However, with the Premo force feedback control system, the machine builders are now giving their customers and their spinning experts an innovative tool with which they can get back the familiar “feeling element” for the teach-in – i.e. for setting up the machine for the subsequent automated spinning process. For this purpose, the control is equipped with a handwheel that the operator turns to guide the spinning roller toward the workpiece during infeed.

The contact of the spinning roller with the circular blank is felt on this wheel as well as the resistance, and proportionally: the higher the resistance between the spinning roller and the circular blank becomes, the more the torque changes. In other words, turning the handwheel on the control unit becomes increasingly difficult as resistance increases. This allows the operator to draw important conclusions about the condition and reaction of the material to the application of force. When the operator releases the handwheel, the spinning roller immediately removes itself from the sheet to be processed due to the resistance.

Return to proven know-how

“With this innovation, we have succeeded as the first spinning machine supplier in the world to meet the customer’s wish for such immediate feedback. However, this is not a revival for the sake of nostalgia, but rather a tangible advantage for the more efficient process of potting. With this tangible transmission of power, it can usually be done much faster and more reliably,” says Guido Klekamp, Head of Marketing and Sales at Abacus.

The setting process is often a tightrope walk, Klekamp continues, since the operator must rely entirely on the eye without the aid of a force feedback control system and finds it more difficult to estimate the force applied to the blank: With too little force, the desired geometry is not achieved or is achieved too slowly. Under excessive pressure, on the other hand, there is a risk of overstressing the material and damaging the blank. “The right intuition coupled with experience counteracts this risk. Thus, going back to proven know-how offers real progress and added value,” adds Derk Weber.

Force feedback control for new and existing plants

Particularly when changing the desired geometries for other products, but also when changing material batches, the time and effort required for teach-in can be significantly reduced. In this way, machine availability is noticeably increased.

The basic principle of measuring the force acting on the workpiece and reporting it back to the spinning process controller is not new in itself. Abacus has long since implemented this for continuous monitoring and optimization of the ongoing spinning process as well as for sustainable lifecycle management. What is new, on the other hand, is that this force measurement can also be used for “teach-in in the twinkling of an eye”.

The Premo force feedback control is available as an option for all new Abacus spinning machines, but can also be easily retrofitted to all existing Premo lines.

Abacus mechanical engineering

Abacus Maschinenbau GmbH, founded by Derk Weber and Thorsten Beling in 1991, is active in the development, design and construction of machine tools. Especially the development of software and control concepts according to customer requirements is more and more in the foreground. The Osnabrück-based company can work on the basis of sketches, dimensional specifications or existing partial designs in individual development phases, but also as a complete, end-to-end partner in order to realize the customer’s automation ideas in a customized manner. In addition to tool and special machine construction, contract manufacturing is an important and integral part of the company. On-time and precise contract manufacturing in the areas of CNC turning, CNC milling, EDM drilling, wire erosion, welding work and the assembly of components complete the range of services.