If you only look at the purchase price when buying sanding tools, you are saving in the wrong place. The Lukas-Erzett Turbo (SLTT) abrasive flap discs are proof of this.

At first glance, Lukas SLTT flap discs often appear more expensive than conventional roughing or flap discs due to their unit price. But if you do the math, you will quickly realize that the actual grinding costs per kilogram of material removed may be lower with Lukas-Erzett Turbo abrasive flap discs than with rough grinding discs and standard flap discs – if you can simply achieve more in less time with the SLTT flap discs. The manufacturer provides an example:

– Price standard rough grinding wheel: approx. €1.50 – stock removal: 1.5 kg – processing time: 44 minutes ➔ Grinding costs per kilogram of stock removal: €24.50

– Price standard flap disc: approx. €2.00 – stock removal: 0.9 kg – processing time: 16.8 minutes ➔ Grinding costs per kilogram of stock removal: 17.37 €

– Price of Lukas SLTT flap discs: around5.00 € – Removal: 2.4 kg – Processing time: 34 minutes ➔ Sanding costs2) per kilogram of removal: 12.67 €

This means that the Lukas SLTT flap discs would not only be more efficient, but also more economical.

Longer service life – fewer tool changes and reduced costs

Longer service life – fewer tool changes and reduced costs

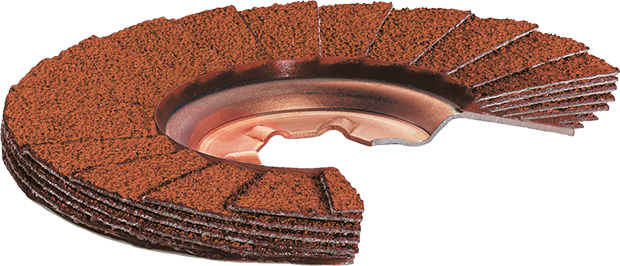

Frequent tool changes not only cost material, but also valuable time. The longer service life that Lukas-Erzett claims for the SLTT flap disc also leads to advantages here. The secret lies in the design, among other things: the flat position of the sickle flaps reduces wear. There are a particularly large number of abrasive grains in the outer area of the tool, which results in a particularly high removal rate per minute. And: When the upper flaps wear, fresh abrasive coating from the flaps below is exposed. This means that the SLTT flap discs remain “sharp” for longer – and can work over a significantly larger area with consistently high performance. The abrasive discs have a particularly stable, robust steel backing plate, which ensures a high level of safety without the risk of breakage.

Faster removal – for greater efficiency in every application

More material removal also reduces costs. Whether in the workshop, during assembly or in series production: The faster and more reliably a sanding tool works, the more cost-effective the entire process is. According to the manufacturer, Lukas-Erzett’s Turbo (SLTT) abrasive flap discs, for example, ensure an above-average removal rate per minute thanks to their sickle flap shape, grit distribution and high concentration of abrasive grit in the outer area – while requiring less force.

According to Lukas-Erzett, a single, cleanly guided grinding process is often sufficient instead of several passes, as is necessary with classic flap discs or rough grinding wheels. This saves time and significantly increases productivity. At the same time, employees are noticeably relieved by the reduced effort, reduced vibrations and smooth running.

According to the supplier, the machines used also benefit: Where less pressure is required, wear on the spindle, bearings and motor is reduced – as is the running time. This saves potential repair and maintenance costs as well as expensive energy.

Uniform surfaces – less reworking, higher quality

Lukas-Erzett promises that its flap discs will help users achieve the desired surface quality more quickly, as each additional sanding pass and each time-consuming reworking process costs time, money and nerves. The Turbo flap discs (SLTT) are intended to make a further decisive difference here.

By repeatedly exposing new abrasive grains in the working area of the flaps, the wheel remains sharp and efficient throughout its entire service life. The combination of precise grit, optimum pressure behavior and smooth running enables clean work – when chamfering, deburring and rough grinding as well as when processing weld seams. The good heat dissipation of the steel plate also ensures cool grinding and makes little reworking necessary.