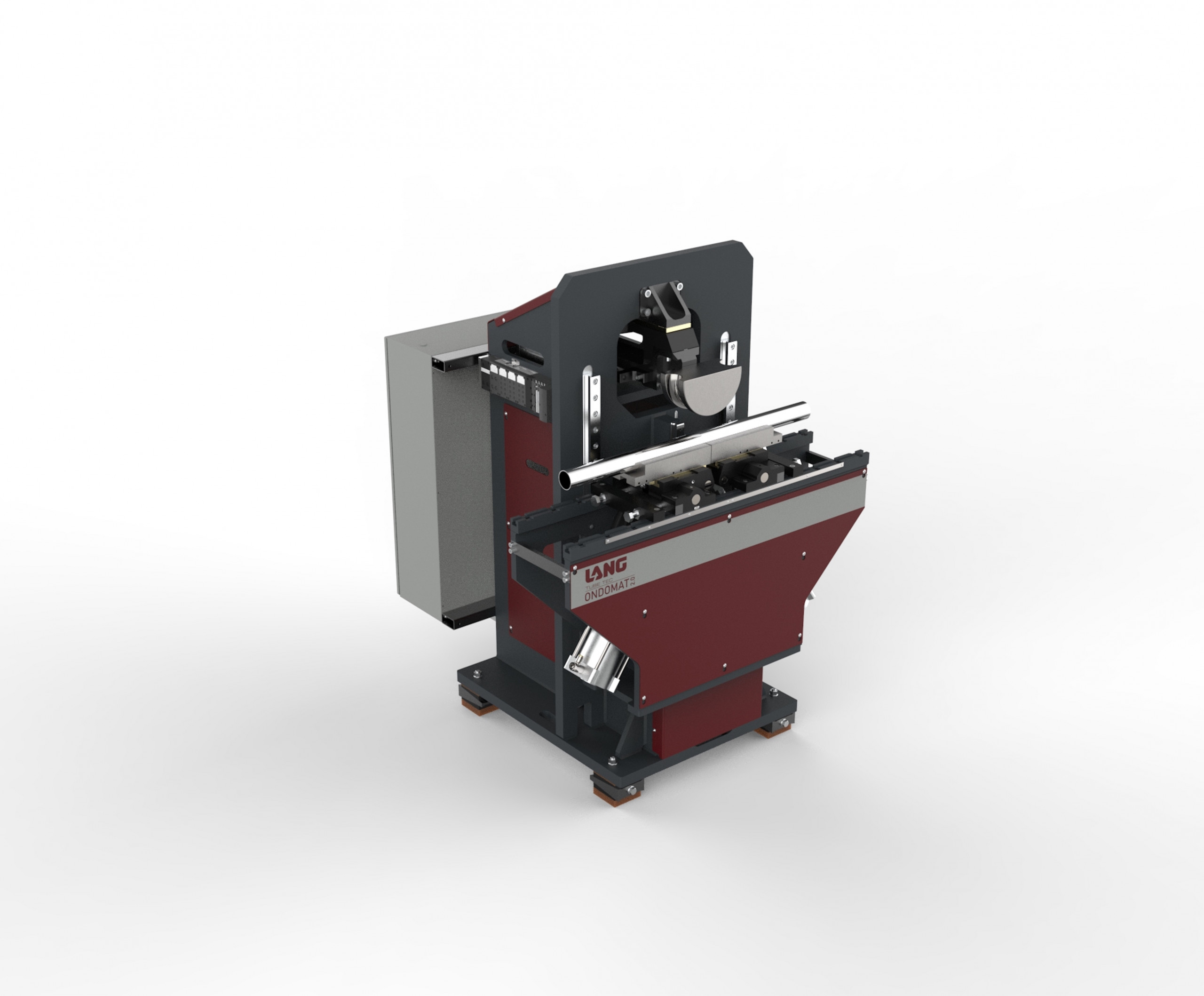

“Ondomat 2.0”: Lang Tube Tec presents new all-electric tube and profile bending machine for mandrel-less bends.

Lang Tube Tec, manufacturer of tube bending machines, is launching a real novelty on the market with the “Ondomat 2.0”: The fully electric tube and profile bending machine for mandrel-less bends is not only the company’s first machine from the “Vertical Bending Direction” series, but Lang Tube Tec says it is currently the only manufacturer to offer a fully electric Ondomat. Along with Dengler Tube Tec, the Lang Tube Tec brand is one of two brands that operate together under the umbrella of DenglerLang Tube Tec GmbH – a developer and manufacturer of CNC bending machines for the automotive and other vehicle industries, aerospace technology, shipbuilding, the offshore industry, the furniture industry and others.

The Ondomat 2.0 also has a CNC axis and is therefore suitable for use in a wide range of different applications. In addition to single bends, the automatic tube and profile bending machine is also capable of performing up to three bends at once in one work step, as well as processing several components simultaneously. The bending angle can always be freely programmed.

© DenglerLang Tube Tec

For Björn Brunner, project manager at Lang Tube Tec, the focus during the development of the machine was always on taking the customer’s interests into account: “The beauty of our Ondomaten 2.0 is that the machine can be used in a very individual way: as a manually controlled variant with a necessary safety concept and, due to a corresponding interface, also in combination with a cobot or as a completely unmanned production cell. In addition, with the help of an extensive selection of equipment modules, we can adapt the machine precisely to individual customer requirements and thus respond directly to their respective needs.”

In addition to its versatility, the Ondomat 2.0 is characterized above all by its ease of use: Based on the integrated “Simatic S7-1500” controller from Siemens, both the entire setup cycle can be performed automatically and operation is intuitive. In addition, the space-saving design allows good accessibility for maintenance purposes. The tube and profile bending machine is also extremely robust and designed for an extremely long service life.

“Customers who use Ondomaten 2.0 should feel a significant ease in their manufacturing process,” explains Björn Brunner. With this in mind, the team of experts at Lang Tube Tec paid particular attention to keeping the noise level of a running Ondomaten 2.0 as low as possible when designing the machine. In addition, the machine enables a 65 percent reduction in energy consumption and guarantees a clean working environment entirely without oil leaks. The machine complies with all existing safety regulations according to EN 60204, EN ISO 13855, EN 61496-1 as well as EN ISO 13850.