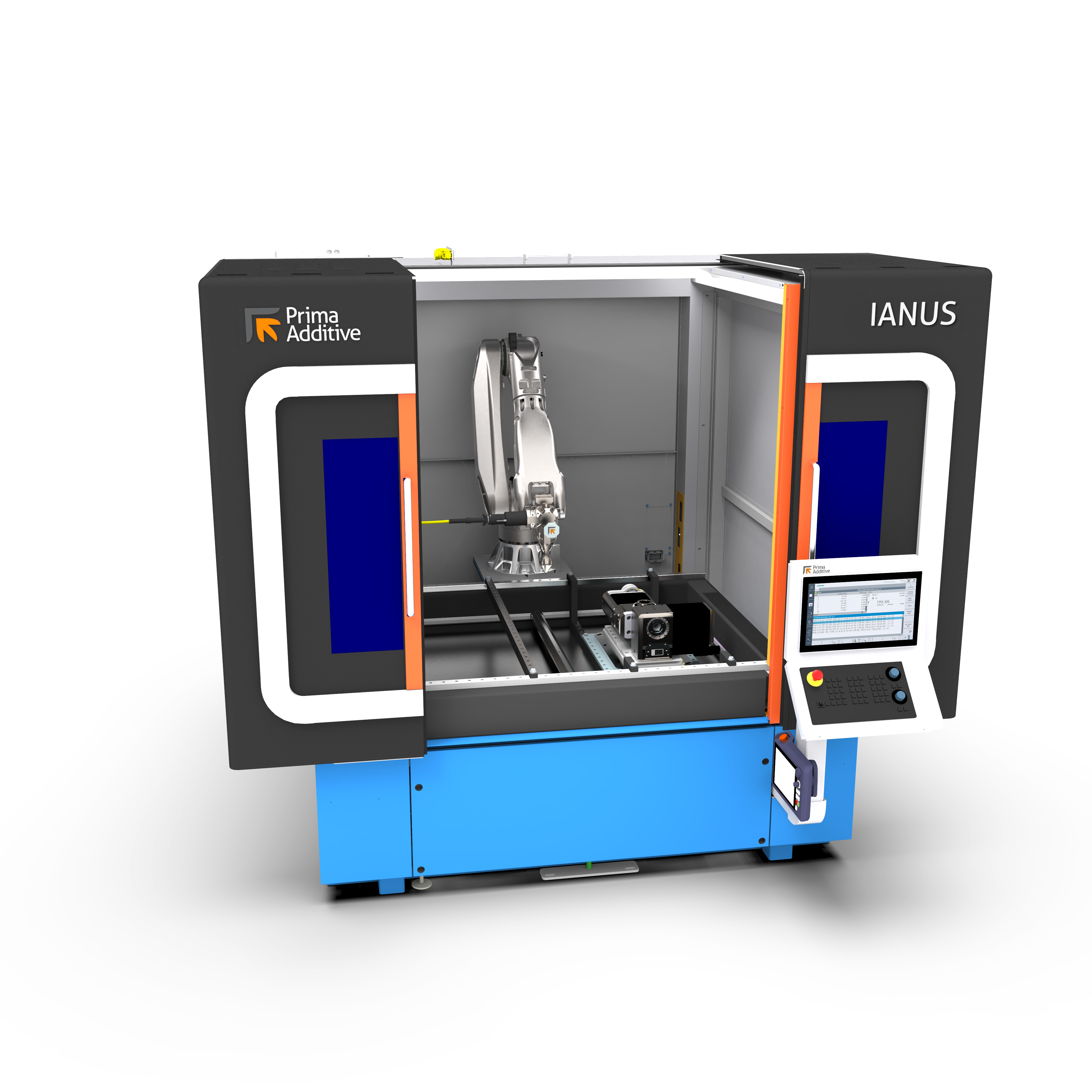

At the trade show in Munich, Prima Additive exhibited the Ianus Cell at the Siemens booth (Hall B6, Booth 302). Siemens is an important partner for Prima Additive, whose solutions enable the great potential of the Ianus multiprocess robotic cell.

© Prima Additive

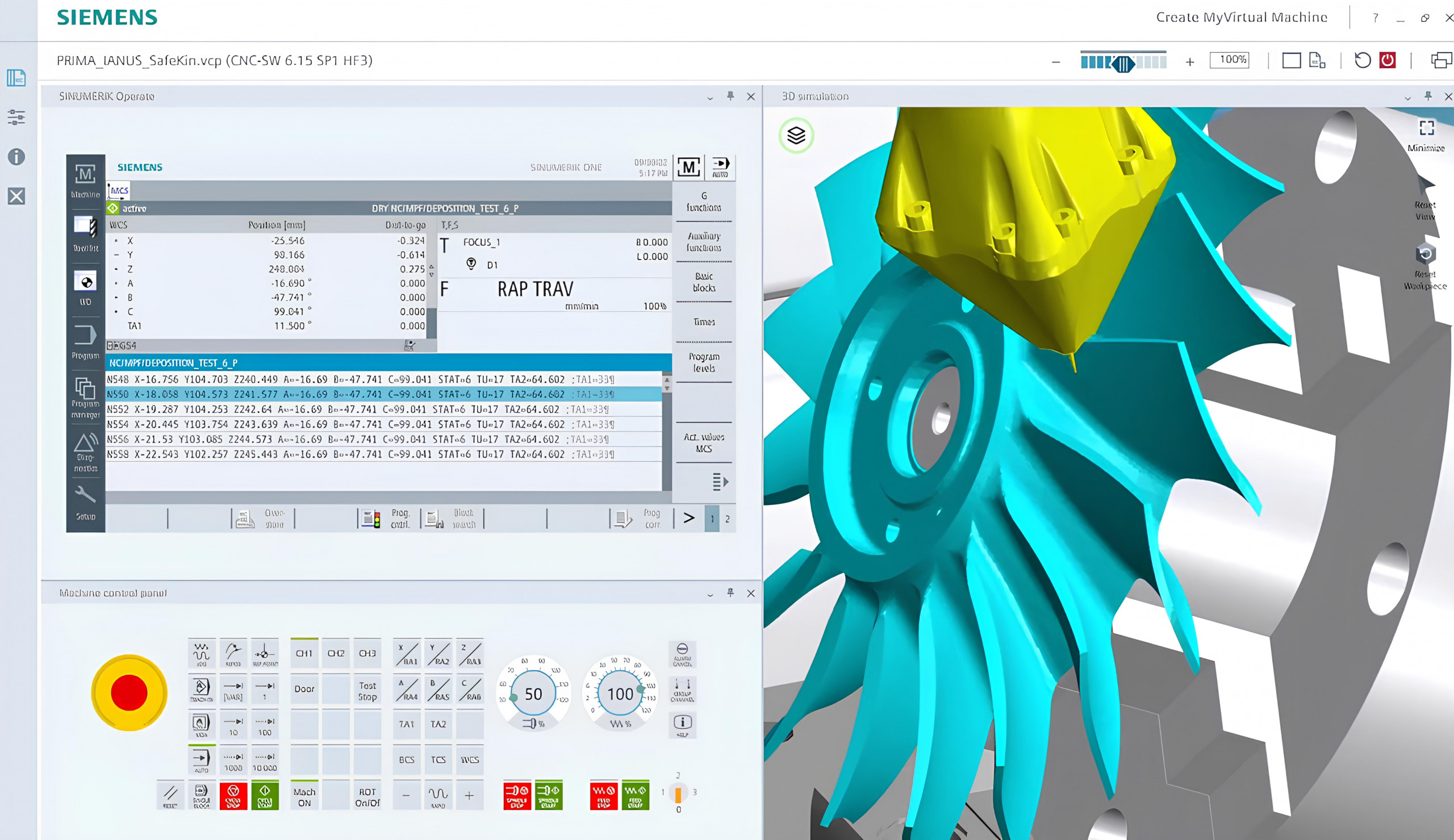

The combination of Siemens and Prima Additive technologies is evident in the development of the Ianus cell and especially in the coordination of the robot arm and CNC through the Sinumerik “Run MyRobot / Direct Control” function. This feature allows the user to operate the machine and robot cell from a single control panel and, most importantly, to program the robot using the typical commands of a machine tool controller. So he does not need to know any additional robot-specific programming language. In addition, thanks to integration with the Siemens systems on which this platform is based, the Ianus cell can be easily networked with other machines present in the company.

At the Siemens booth, the Ianus Cell with a workspace of 1600 x 1200 x 700 mm will be on display in operation, equipped with the laser welding function, one of the four processes that can run on it: In addition to laser welding, it is possible, for example, to use it for Direct Energy Deposition based on powder or metal wire as the starting material, but also for laser hardening.

The fact that this robotic cell also performs processes outside the spectrum of additive manufacturing is testament to the Italian company’s desire to leverage its years of experience to position itself in a larger market for advanced laser solutions.

The name of the machine comes from the Roman god Ianus with his two faces. This indicates that the Prima Additive Ianus robotic cell can be configured to perform two different processes in the same machine. This makes it possible to switch from one application to another by simply swapping the head installed on the robot arm, similar to a tool change, increasing the overall flexibility of the system.

In addition, the flexibility of the system is increased by the possibility of installing different laser sources with different wavelengths in the same machine. For example, the system can be equipped with an infrared laser and a blue laser to use both within the same process to effectively machine any metal, enabling advanced multi-material applications.

To realize the full potential of this solution, Siemens’ Create MyVirtual Machine software can create a true digital twin of the system. This has proven extremely useful in facilitating design work during the machine development and optimization phases, which significantly reduces a product’s time to market.

Web:

primaadditive.com