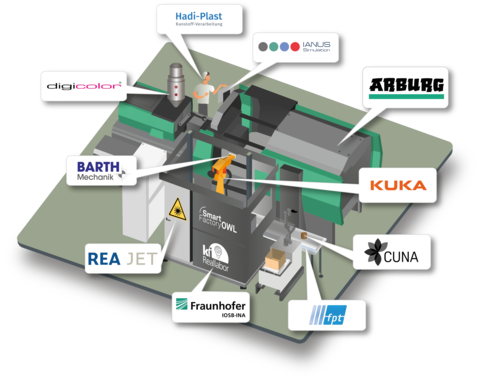

Exploiting the potential of artificial intelligence: This is the goal of a cooperative of ten partners initiated by Fraunhofer IOSB-INA. The basis for this: data from a real laboratory. In June, the SmartFactoryOWL will now start production of what is probably Germany’s smartest cup – with a KR Cybertech from Kuka. Another look at the factory of the future.

Real laboratories drive innovation in Germany. At the SmartFactoryOWL, a real laboratory for artificial intelligence (AI) in Lemgo, Fraunhofer IOSB-INA is researching the industrial data economy of tomorrow together with Kuka and other partners. The central question: How can industry make better use of AI technologies?

Smart cup created in the real lab

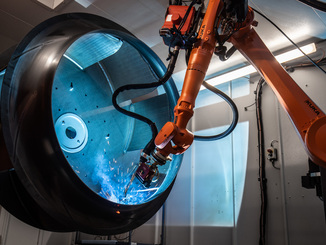

To this end, the AI Reallabor collects data streams from plants and processes and makes them freely available to AI developers and companies on a platform. In June, the SmartFactoryOWL will now become an experimental field: the fully networked and AI-supported production of a reusable cup made of a bio-based plastic that does not require any petroleum at all will start. The special feature: Not only the material used for production from renewable raw materials is sustainable, but also the recycling cycle specially organised by Cuna Products GmbH. In the production line, a KR Cybertech from Kuka removes the cups from the injection molding machine and then holds them up to a laser, where the cups are labeled and provided with a label. The robot then places the returnable cups on a conveyor belt.

Sustainable and data-integrated production

The Federal Ministry for Economic Affairs and Energy is funding the AI Reallabor with two million euros. Since 2016, the SmartFactoryOWL has been bringing together companies and research institutions to test solutions for the factory of the future in real interaction scenarios. “When Fraunhofer IOSB-INA approached us with the request, I was excited about the potential,” says Bernd Besserer, Global Key Account Manager and Team Leader Regional Sales DACH_2 at Kuka. “Technological use cases give us valuable experience to drive Industry 4.0. And on the other hand, AI providers get real data with which they can develop and improve custom-fit solutions for industry.”

Nissrin Perez, project manager for real production at Fraunhofer IOSB-INA, is also convinced that the open database will mean great progress for the German plastics industry. Even more: “We want to understand and localize errors and causes in production processes. To do this, components and systems need a common, interoperable language. The basis for this is the data streams that we will be collecting in the future as part of ‘Collaborative Condition Monitoring’.”

Web:

www.kuka.com