With its Plug&Play solutions for automated cutting, the Wiesbaden-based system house provided impetus at Euroblech in terms of efficiency, process stability, machine safety and ease of use. The thematic highlights: E°SLC 89 Safety and E°Cut.

Automation and digitalization are the key to improved profitability and competitiveness, especially in times of a shortage of skilled workers and challenging framework conditions. The interest of trade visitors and the level of discussions at the Eckelmann stand were correspondingly high. “In the sometimes very intensive discussions, we were able to highlight the technical excellence, high flexibility and reliability of our solutions, which were specially developed for modern, industrial machining processes,” says Oliver Elias Sebastian, Senior Sales Manager Automation Products at Eckelmann.

Safety control unit E°SLC 89

With the Eckelmann Group’s safety portfolio, all safety-relevant applications of machines and systems can be operated. The E°SLC 89 safety control platform, a SIL3 and PL e certified safety master for cutting machines, was a particular focus at Euroblech. Thanks to the close interlocking of the safety PLC and CNC, even complex and fine-grained safety logic can be mapped in the PLC. Safe communication to the drive level and all safe IO modules takes place via FSoE (FailSafe over EtherCAT). The standardized control platform offers further advantages in terms of procurement, warehousing, training and service.

E°Cut packages

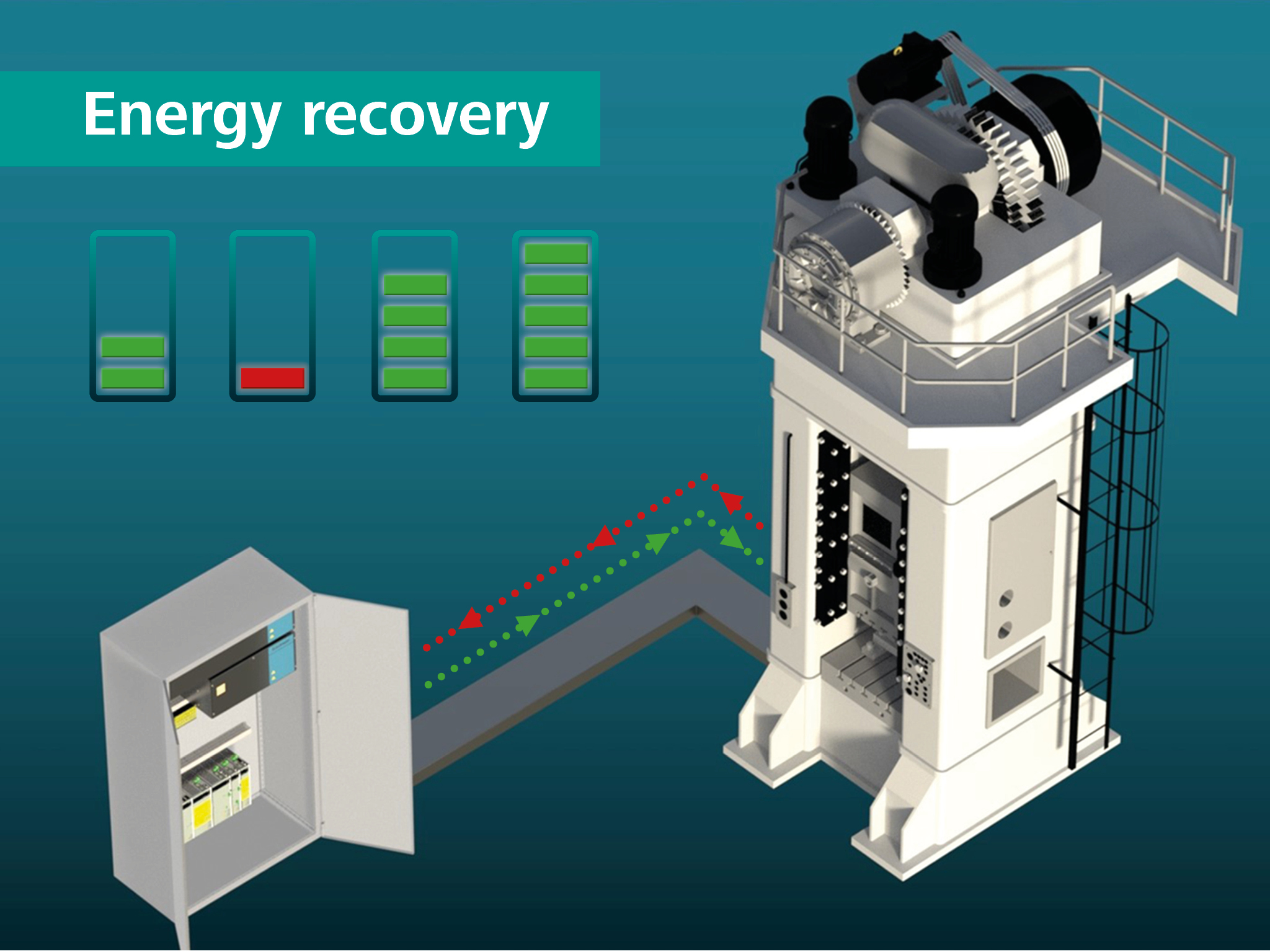

Eckelmann’s E°Cut automation packages cover all types of sheet metal cutting machines and application scenarios. They have been developed from practical experience and are based on more than 40 years of expertise: from the light industrial segment to high-end and combination machines, from plasma, laser and oxyfuel to waterjet cutting. “When it comes to selecting cutting equipment, we are open to all technologies so that customers have a free choice from the standard cutting technology providers,” emphasizes Dr. Marco Münchhof, one of the three members of the Eckelmann Group’s Executive Board, who was also on site in Hanover. Eckelmann adapts and continuously adds to the applications so that they fit in harmoniously with the machine concept and the look and feel of the machine manufacturer. Specifically, Eckelmann presented the “E°Cut Elements Box”, measuring just 60 cm x 50 cm x 25 cm, the latest addition to its product portfolio: The ready-to-plug-in box offers a quick and simple way to automate E°Cut Light Industrial machines with a controller, servo controllers, cables and motors. The E°Cut Elements software is included as standard, and the CAD-CAM software is available as the perfect complement. Thanks to the free configurability of the CNC kernel, the E°Cut solution also supports a wide variety of kinematics for the 3D future of bevel cutting. Various correction functions guarantee the optimization of the cutting quality.

Intuitive E°Cut HMI user interface

The intuitive E°Cut HMI user interface is a powerful tool for the OEM for configuring and commissioning the machine, as well as a service tool throughout the machine’s entire life cycle. In the daily production process, it offers the advantage that the machine can be controlled safely and conveniently by the respective user, even with only brief instruction. Up-to-date documentation is provided on the Eckelmann E°EDP platform. “The trade visitors were particularly impressed by the ease of use and the clarity of the information available,” summarizes Oliver Elias Sebastian.

Web:

www.eckelmann.de