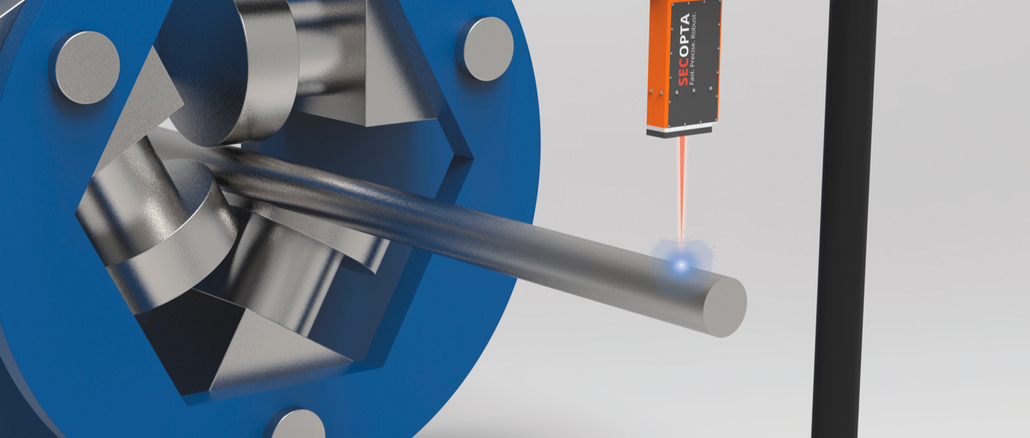

At Tube/Wire, Secopta will present its LIBS system for fully automatic inline mix-up inspection for the first time for the inspection of long products made of black steel.

© Secopta

The fully automated Positive Material Identification (PMI) system has already proven its worth in many bright steel mills. Now Secopta offers the “FiberLIBS black bar” system for the first time also for black steel. The laser system drastically reduces the manual effort required for material identification and in many cases eliminates the need for mechanical sample preparation. With a detection rate of more than 99.9 percent, LIBS reliably ejects material whose composition does not meet the specifications from the process. In this way, it avoids the confusion of semi-finished products before they are further processed.

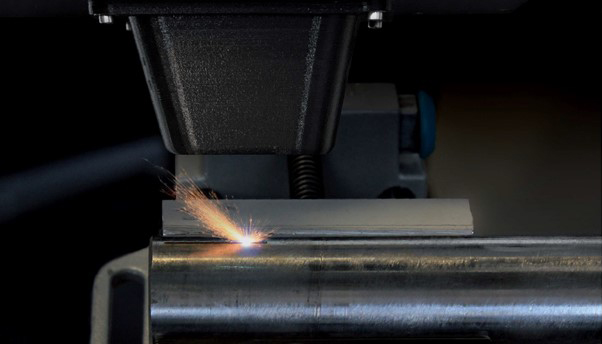

Secopta has adapted the integrated sample preparation especially for the inspection of black steel. It removes surface contaminants such as rolling skins, oil or other interfering factors fully automatically. This makes it possible for the first time to also test this material without prior mechanical sample preparation.

Against the background of the demand for smaller batch sizes and the constantly growing number of steel grades, the importance of reliable material identification in the entire process chain is constantly increasing.

Dr. Christian Bohling, one of the managing directors of Secopta analytics GmbH, sees laser-optical material analysis as the solution: “In the rolling mill, many processes are reliably automated, and the risk of mix-ups is low. But as soon as humans come into play, things look different: There are manual work steps with a high risk of mix-ups, for example, when the wrong starting or intermediate material is mistakenly taken from a store or the wrong billets are loaded in the reheating furnaces. This is particularly critical when it comes to safety-relevant components, where mix-ups have serious consequences.”

Other areas of application for LIBS systems are the analysis of the melt in the steel mill, the inspection of delivered scrap or the mix-up control of steel billets before reheating. There, too, LIBS avoids that mix-ups are not detected and products with the wrong material properties are delivered to the customer.

Tube Hall 6, Booth J11

© Secopta

The technology in detail

LIBS (Laser Induced Breakdown Spectroscopy) systems analyze the composition of the alloy of metals inline and thus enable almost 100 percent reliable material identification – fully automatically and virtually in real time. Separate analysis of samples in the laboratory is no longer necessary. During the measurement, a laser beam is focused on the material from a safe distance. Due to the energy superelevation, small amounts are ablated and transferred into a plasma. In this state, the bonds of the various molecules are broken and free charge carriers (electrons, atoms, ions) are excited. As the plasma regresses, they emit an element-specific light that is detected by a spectrometer and evaluated up to 1000 times per second. The results are compared with the corresponding melt analysis, which was transmitted directly from the plant’s database to the LIBS system by the PLC at the beginning of the measurement. Since the material evaporates instantaneously, the heat input to the sample material is very low. In order to be able to perform fully automatic material identification with LIBS despite heavy contamination, a laser-based pre-cleaning process integrated into the measuring head removes oxide layers and dirt.

Web:

www.secopta.de