Based on continuous market analysis and discussions with customers, in recent months Saronni has arranged to add some levelers to its product range.

The main reasons can be summarized in two main points:

– Strong focus on the customer’s process need: High-performance materials, precisely defined thickness ranges and very demanding flatness tolerances require levelers specifically designed for the specified operating points. The solution with multiple straightening rolls (from 9 to 21), counter rolls in different levels (4hi or 6hi straighteners) and increasingly powerful automation allows Saronni to meet the requirements of practically any production.

– Optimization of the offer: as a consequence of the above point, but no less important, the development of this range allows benefits not only in terms of specific services, but also in terms of cost. In fact, this extended range of standard levelers allows to choose the most suitable solution for the specific needs of the customer and, in most cases, to avoid an oversized machine. This advantage is clearly noticeable with smaller lines.

All existing features (for example, the proprietary A.S.A. “Automatic Straightening Adjustment” software) and options previously offered on Saronni lines will continue to be available.

© Saronni

Surface-friendly blanking line for aluminum

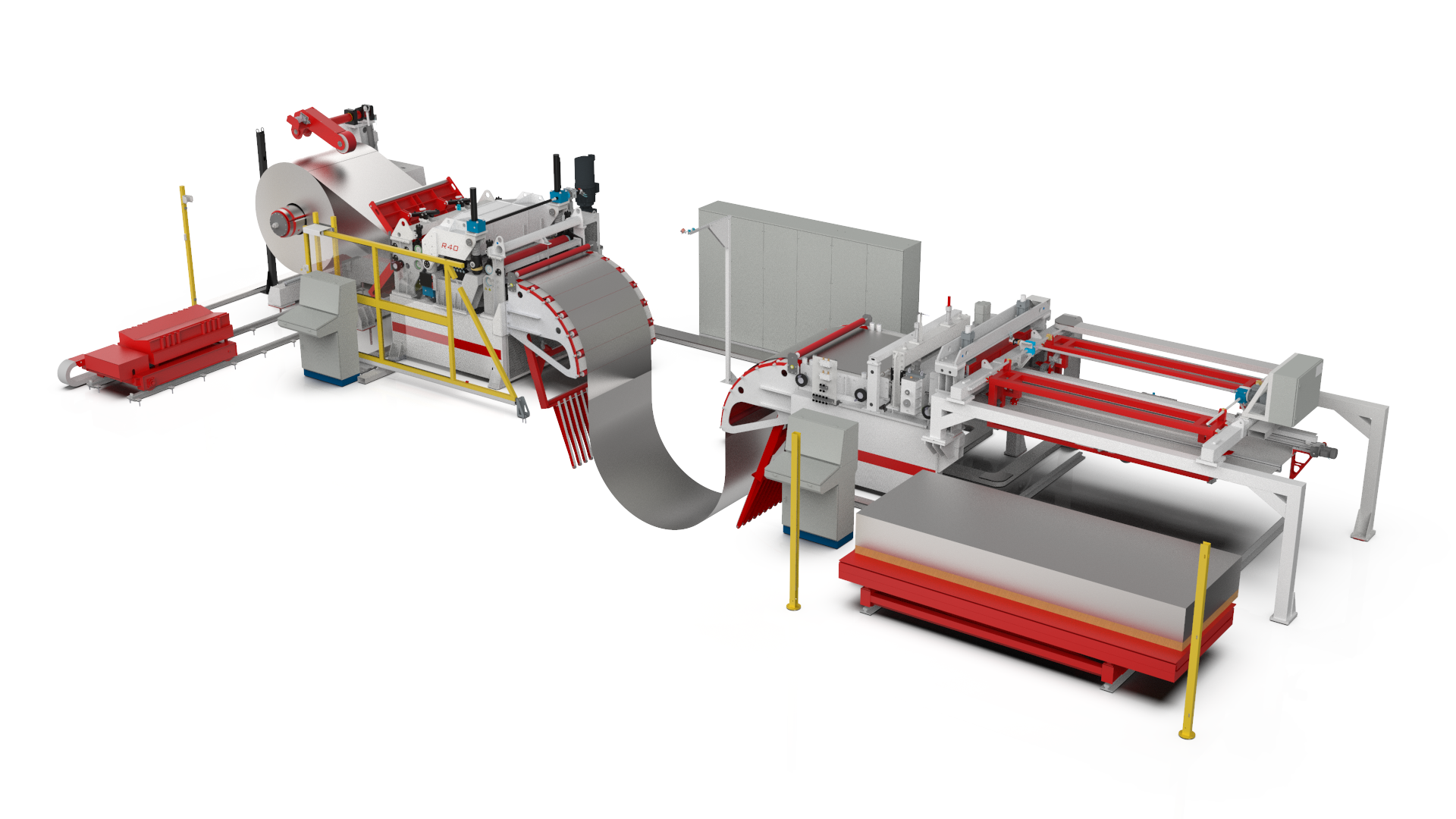

The blanking line, specially designed and developed for aluminum, with automatic coil change and automatic insertion of the strip head up to the hydraulic shear, can be equipped with an automatic end-of-strip cycle to reduce coil change time. The equipment has been designed with special precautions and solutions to maintain the surface finish of the material throughout the process. The automatic stacking system with mobile platform, is designed and manufactured according to the customer’s specific requirements, adapted to the logistic needs of the customer.

Complete line enables processing of strip widths up to 1,500 mm and thicknesses up to 3 mm. Thanks to the proprietary A.S.A. “Automatic Straightening Adjustment” software, the line also optimizes itself.

Web:

www.saronni.it